Preparation method of chitosan/polyvinyl alcohol hydrogel dressing

A polyvinyl alcohol and polyvinyl alcohol solution technology, applied in medical science, bandages, etc., can solve the problems of poor hydrogel strength, affecting wound healing, human tissue damage, etc., to overcome the strength difference, promote rapid healing, good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh chitosan powder with a relative molecular weight of 5w, place it in an acetic acid solution with a mass percent content of 1%, and stir the solution to form a chitosan solution with a mass volume concentration of 1%. Weigh 10 g of polyvinyl alcohol, add it to 90 ml of distilled water, and stir at 85°C for 3 hours until a clear and transparent polyvinyl alcohol solution with a mass fraction of 10% is formed. Mix the chitosan solution and polyvinyl alcohol solution according to the volume ratio of 1:1, stir evenly, and let it defoam under vacuum; then pour the chitosan / polyvinyl alcohol mixed solution into the mold, freeze and thaw twice process it after 60 Co gamma rays were irradiated, and the radiation absorbed dose was 30kGy, and a chitosan / polyvinyl alcohol hydrogel dressing was obtained.

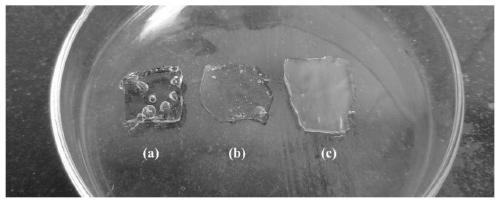

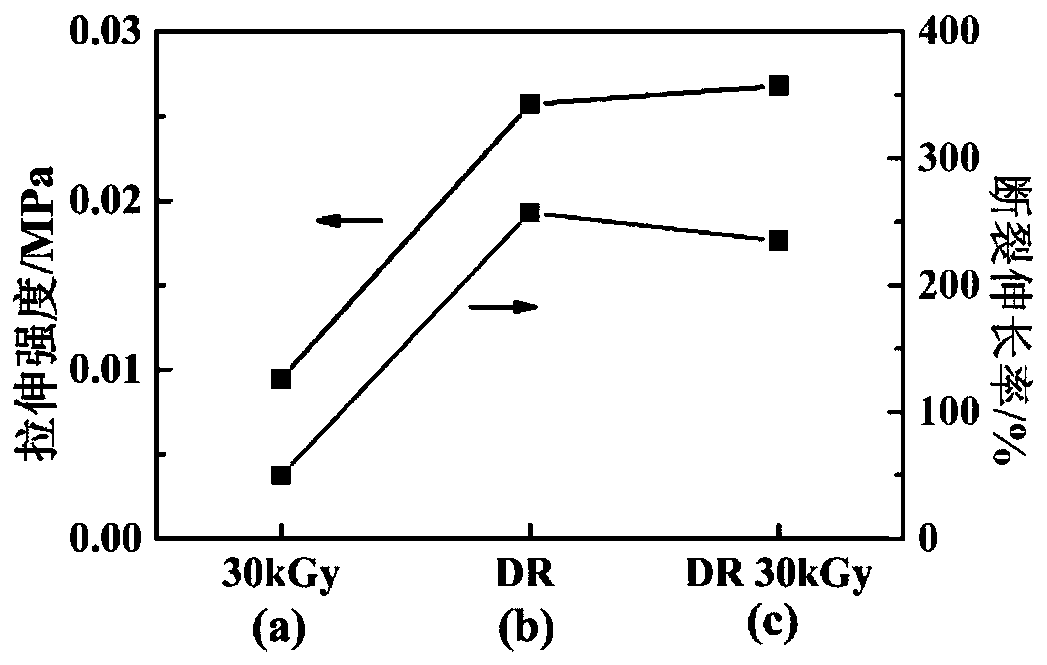

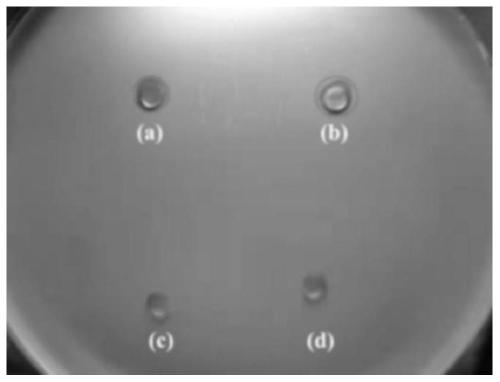

[0032] The appearance diagram, mechanical performance diagram, and antibacterial performance diagram of the chitosan / polyvinyl alcohol hydrogel dressing obtained in the pre...

Embodiment 2

[0035] Weigh chitosan powder with a relative molecular weight of 5w, place it in an acetic acid solution with a mass percent content of 1%, and stir the solution to form a chitosan solution with a mass volume concentration of 1%. Weigh 10 g of polyvinyl alcohol, add it to 90 ml of distilled water, and stir at 85°C for 3 hours until a clear and transparent polyvinyl alcohol solution with a mass fraction of 10% is formed. Mix the chitosan solution and polyvinyl alcohol solution according to the volume ratio of 1:3, stir evenly, and let it defoam under vacuum; then pour the chitosan / polyvinyl alcohol mixed solution into the mold, freeze and thaw once process it after 60 Co gamma rays were irradiated, and the radiation absorbed dose was 30kGy, and a chitosan / polyvinyl alcohol hydrogel dressing was obtained.

[0036] The chitosan / polyvinyl alcohol hydrogel dressing swelling ratio that the present embodiment obtains is 153%.

Embodiment 3

[0038] Weigh chitosan powder with a relative molecular weight of 1-2w, place it in an acetic acid solution with a mass percent content of 1%, and stir the solution to form a chitosan solution with a mass volume concentration of 2%. Weigh 10 g of polyvinyl alcohol, add it to 90 ml of distilled water, and stir at 85°C for 3 hours until a clear and transparent polyvinyl alcohol solution with a mass fraction of 10% is formed. Mix the chitosan solution and polyvinyl alcohol solution according to the volume ratio of 1:1, stir evenly, and let it defoam under vacuum; then pour the chitosan / polyvinyl alcohol mixed solution into the mold, freeze and thaw twice After processing, the hydrogel belt mold 60 Co gamma rays were irradiated, and the radiation absorbed dose was 40kGy, and a chitosan / polyvinyl alcohol hydrogel dressing was obtained.

[0039] The chitosan / polyvinyl alcohol hydrogel dressing swelling ratio that the present embodiment obtains is 192%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com