Method of isolating 1,3-propanediol, acetic acid and butyric acid from fermentation liquor

A technology of propylene glycol and fermentation broth, applied in the field of bioengineering, can solve the problems of high separation cost, difficult recovery of by-products, etc., and achieve the effects of simple operation, easy recovery and utilization, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

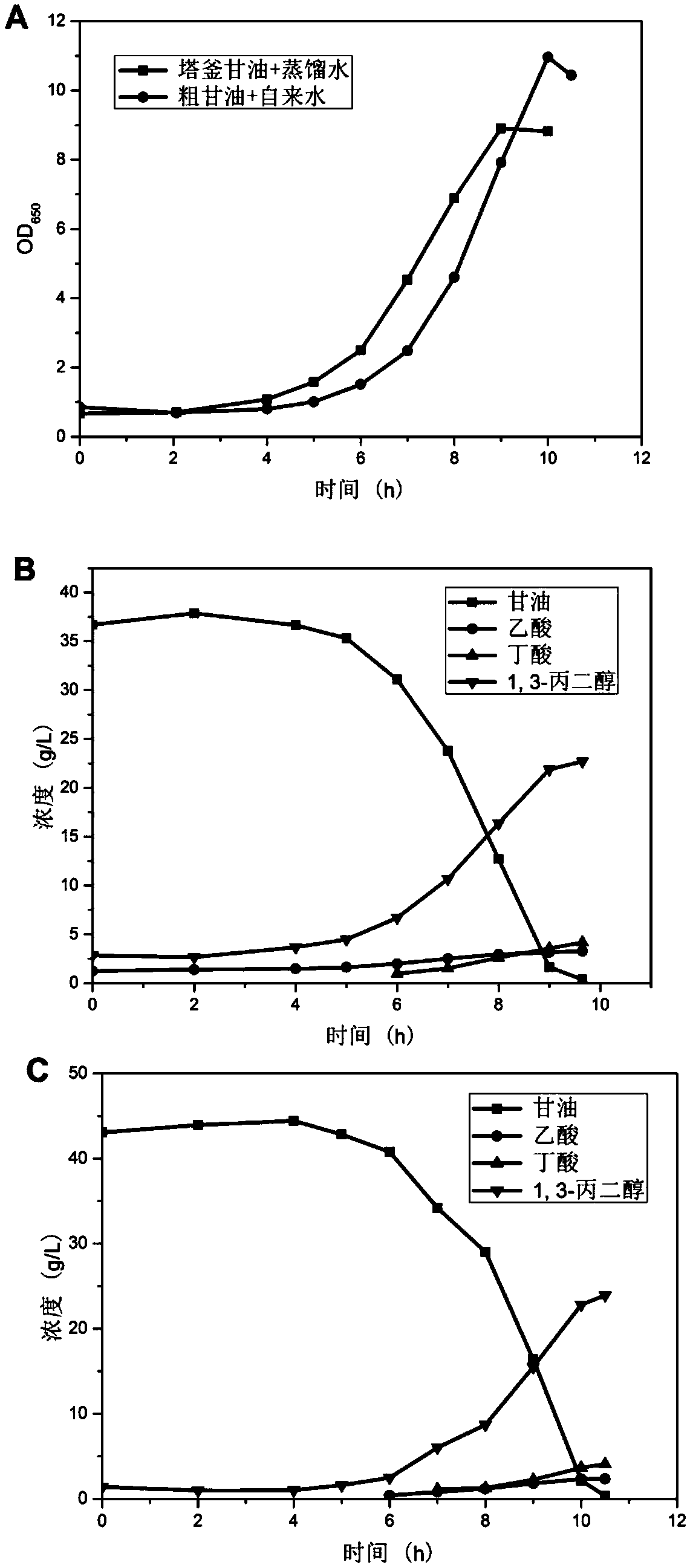

[0034] 1. Preparation of 1,3-propanediol fermentation broth

[0035] The 1,3-propanediol fermentation broth is a fermentation broth prepared by a conventional method and contains 1,3-propanediol, acetic acid and butyric acid.

[0036] The fermentation liquid of the following examples is obtained by using the batch flow of Clostridium butyricum (Clostridium butyricum) to ferment crude glycerol. By adjusting the substrate concentration or feeding time, 1,3-propanediol fermentation with appropriate component content is obtained. Liquid, in which the concentrations of 1,3-propanediol (1,3-PD), acetic acid (HAc) and butyric acid (BA) are 50-100g / L, 6-15g / L and 10-20g / L, respectively. Filter the 1,3-PD fermentation broth through a hollow fiber membrane to remove bacteria and some proteins to obtain a fermentation serum.

[0037] 2. Analysis method

[0038] In the aqueous solution, the content of 1,3-PD, HAc and BA was detected by high performance liquid chromatography. Aminex HPX...

Embodiment 1

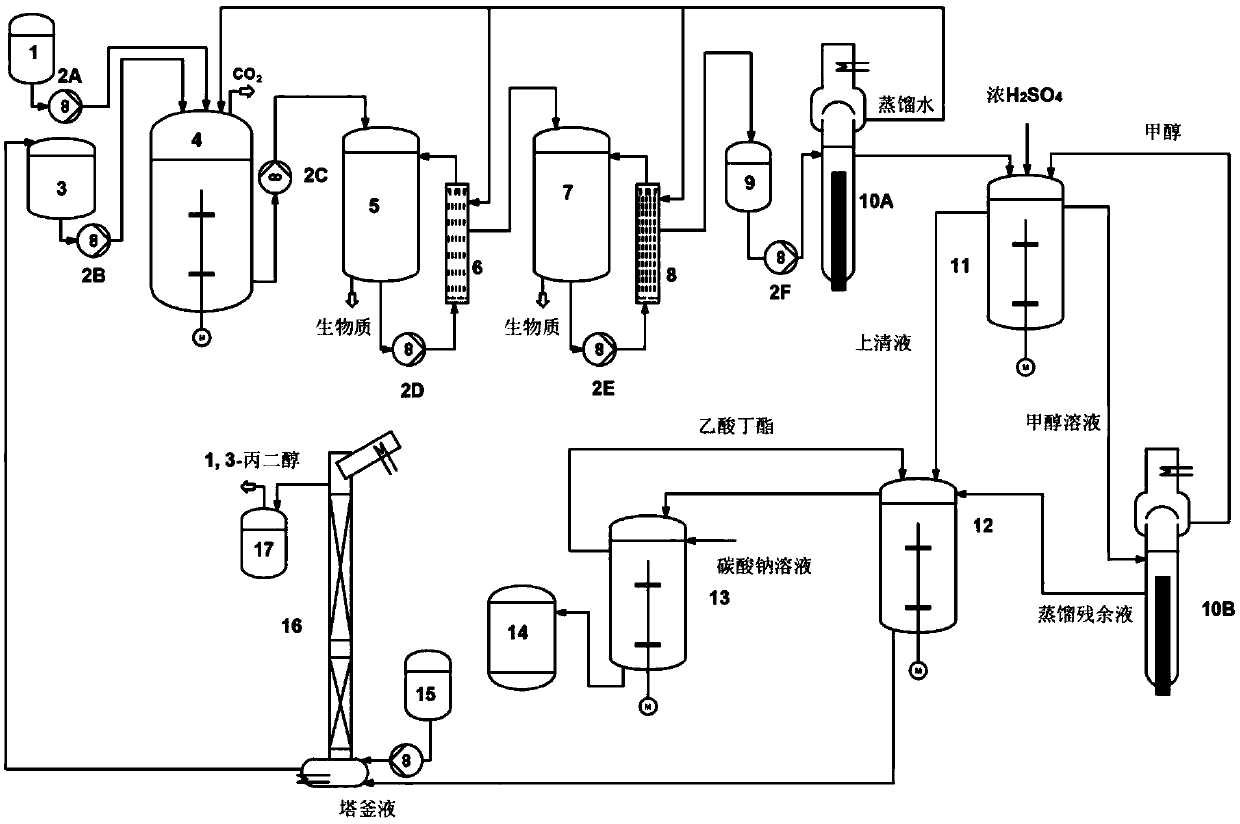

[0042] The method for separating 1,3-propanediol, acetic acid and butyric acid from 1,3-PD fermented liquid comprises the steps of microfiltration, ultrafiltration-concentration-precipitation under acidic conditions-organic solvent extraction-rectification, and the specific steps are as follows :

[0043] 1) The fermented liquid is removed by microfiltration and ultrafiltration to remove impurities such as bacteria and protein to obtain a fermented clear liquid;

[0044] 2) Distilling, concentrating and dehydrating the fermented clear liquid obtained in step 1) to obtain concentrated fermented liquid;

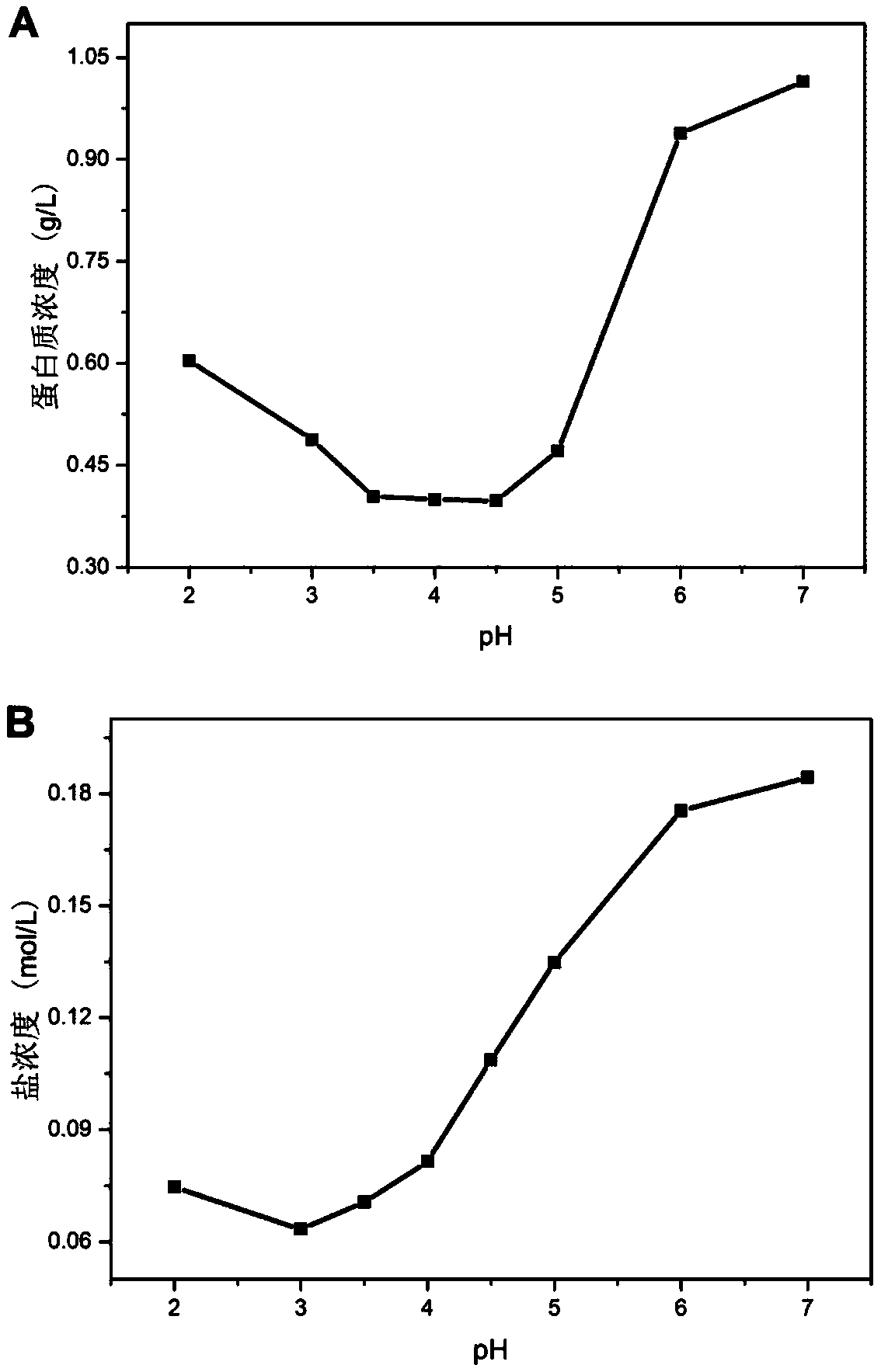

[0045] 3) adding an inorganic acid to the concentrated fermentation broth obtained in step 2), adjusting the pH to acidity, and then filtering to obtain a solid precipitate and a supernatant;

[0046] 4) adding methanol to the solid precipitate obtained in step 3), stirring, washing, and filtering, distilling the filtrate to recover methanol, and retaining the residual liquid;...

Embodiment 2

[0053] Example 2 Membrane Filtration

[0054] The concentrations of 1,3-PD, HAc, BA and glycerol in 1,3-PD fermentation broth were 87.97g / L, 8.59g / L, 16.62g / L, 6.76g / L, respectively.

[0055] 5L of fermented broth was passed through microfiltration membrane and ultrafiltration membrane at flow rates of 18mL / min and 16mL / min, respectively, to remove 99.90% of bacteria and 79.07% of protein in the fermented broth. Add 400mL of water to the last remaining bacteria-carrying liquid, filter again, and repeat three times to reduce product loss. The results are shown in Table 1. The recoveries of 1,3-PD, HAc, BA and glycerol were 99.10%, 98.82%, 96.05%, 75.52%, respectively. The lower recovery of glycerol may be due to its utilization and consumption by microorganisms surviving in the broth. The membrane liquid was mixed with the washing liquid three times to obtain the fermentation supernatant.

[0056] Table 1. Yield of main products after fermentation broth is filtered by membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com