Porcelain formula and manufacturing process

A production process and technology of porcelain, applied in the field of ceramics, can solve the problems of easy generation of fire bubbles, waste of energy, and decrease in glaze gloss, achieve good whiteness and glaze gloss, reduce resource consumption, and lower firing temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

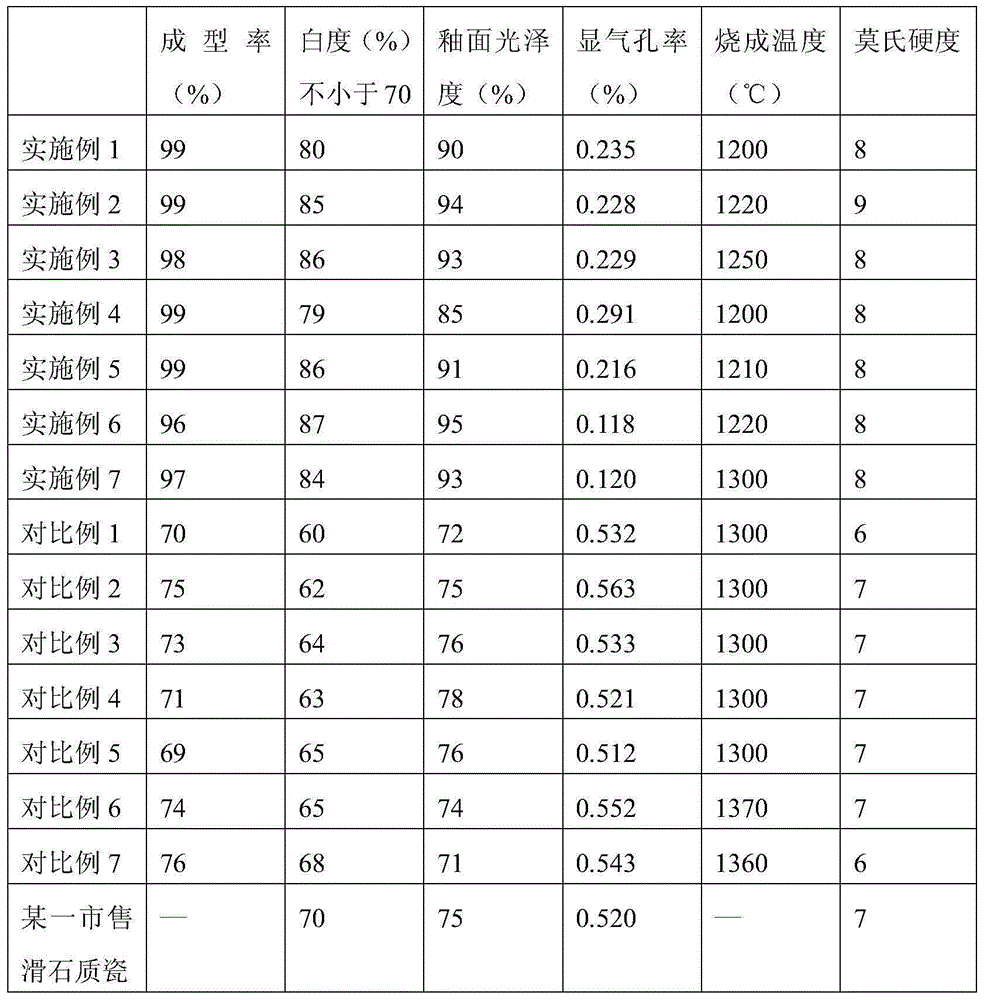

Examples

Embodiment 1

[0030] Prepare raw materials according to the following composition ratio:

[0031] 50 parts of Longyan soil, 20 parts of bone carbon, 5 parts of Mingling clay, 15 parts of talc, 2 parts of sepiolite, 8 parts of Enzhou strange stone powder.

[0032] Porcelain is produced by the following crafting process:

[0033] Step 1: select raw materials and remove impurities;

[0034] Step 2: Longyan soil, bone charcoal, Mingling mud, talc, sepiolite, and Enzhou strange stone powder are prepared according to the above-mentioned parts by weight;

[0035] Step 3: Grind Longyan soil, bone charcoal, Mingling mud, talc, and sepiolite to 800 mesh, sieve and mix with 1200 mesh Enzhou stone powder to obtain powder;

[0036] Step 4: Form the powder according to the design requirements, trim the blank, dry the trimmed blank, and then biscuit at 800°C in a reducing atmosphere containing 3% CO, and polish the biscuit blank;

[0037] Step 5: After glazing the biscuit body, heat and fire it at 1200...

Embodiment 2

[0039] Prepare raw materials according to the following composition ratio:

[0040] 30 parts of Longyan soil, 40 parts of bone carbon, 15 parts of Mingling mud, 5 parts of talc, 6 parts of sepiolite, and 4 parts of Enzhou strange stone powder.

[0041] Porcelain is produced by the following crafting process:

[0042] Step 1: select raw materials and remove impurities;

[0043] Step 2: Longyan soil, bone charcoal, Mingling mud, talc, sepiolite, and Enzhou strange stone powder are prepared according to the above-mentioned parts by weight;

[0044] Step 3: Grind Longyan soil, bone charcoal, Mingling mud, talc, and sepiolite to 1000 mesh, sieve and mix with 1300 mesh Enzhou stone powder to obtain powder;

[0045] Step 4: Form the powder according to the design requirements, trim the blank, dry the trimmed blank, and then biscuit at 820°C in a reducing atmosphere containing 4% CO, and polish the biscuit blank;

[0046] Step 5: After glazing the biscuit body, heat and fire it at ...

Embodiment 3

[0048] Prepare raw materials according to the following composition ratio:

[0049] 20 parts of Longyan soil, 10 parts of bovine bone carbon, 40 parts of Mingling mud, 20 parts of talc, 9 parts of sepiolite, and 1 part of Enzhou strange stone powder.

[0050]Porcelain is produced by the following crafting process:

[0051] Step 1: select raw materials and remove impurities;

[0052] Step 2: Longyan soil, ox bone charcoal, Mingling mud, talc, sepiolite, and Enzhou strange stone powder are prepared according to the above parts by weight;

[0053] Step 3: Grind Longyan soil, bovine bone charcoal, Mingling mud, talc, and sepiolite to 1200 mesh, sieve and mix with 1500 mesh Enzhou stone powder to obtain powder;

[0054] Step 4: Form the powder according to the design requirements, trim the blank, dry the trimmed blank, and then biscuit at 850°C in a reducing atmosphere containing 5% CO, and polish the biscuit blank;

[0055] Step 5: After glazing the biscuit body, heat and fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com