Limestone-wet flue gas desulfurization defoaming method for thermal power plant based on desulfurization defoaming agent

A technology for wet flue gas desulfurization and defoaming agent, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as increased wind resistance and pressure difference, hidden dangers of equipment safety, and large amount of foaming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

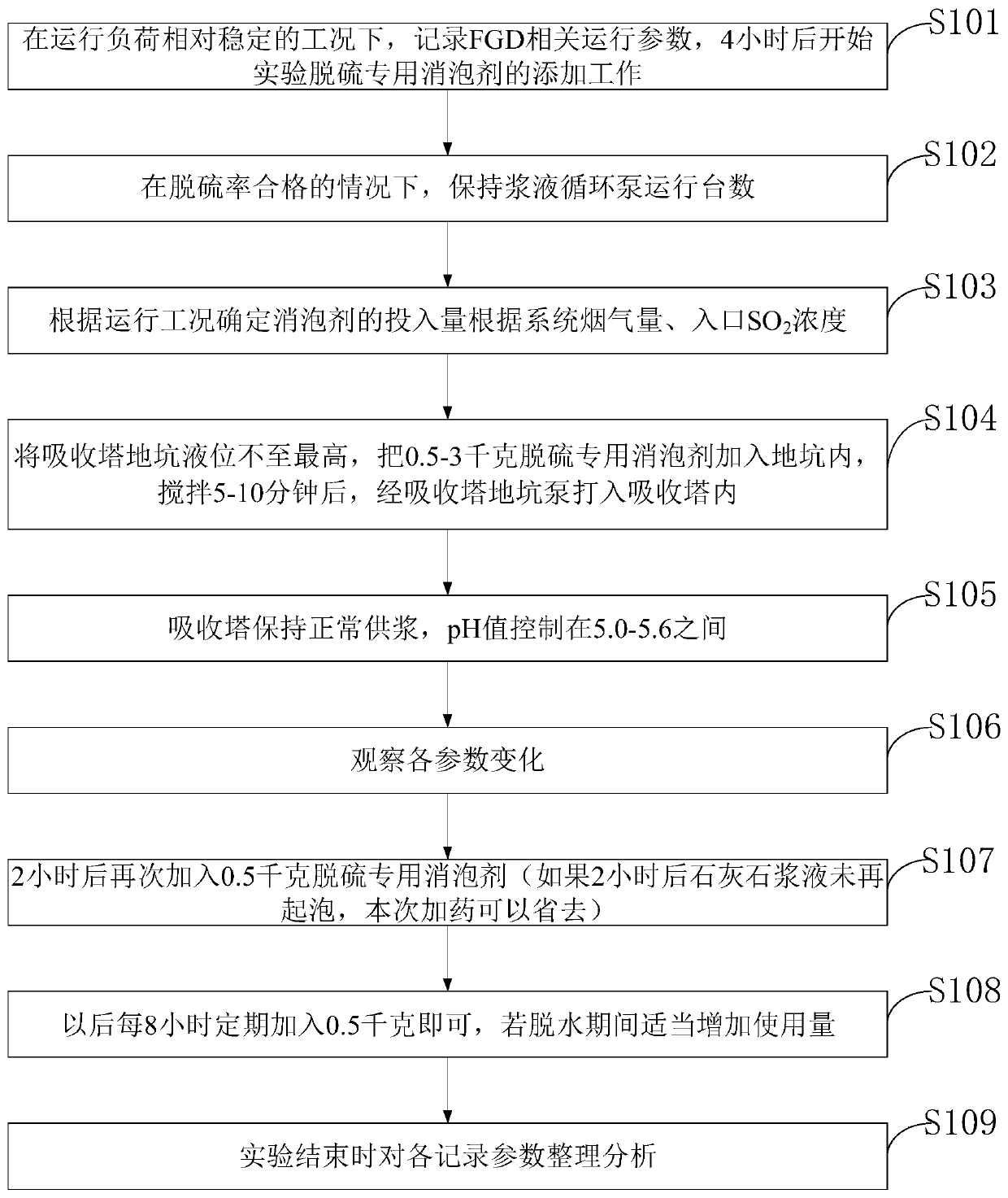

[0032] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0033] Aiming at the problems existing in the prior art, the present invention provides a limestone-wet flue gas desulfurization and defoaming method for thermal power plants (municipal coal-fired heating units, steelworks and coking plants) based on a special defoamer for desulfurization, combined below Accompanying drawing describes the present invention in detail.

[0034] Such as figure 1 As shown, the desulfurization defoamer based thermal power plant limestone-wet flue gas desulfurization absorption tower limestone slurry defoaming method provided by the embodiment of the present invention includes the following steps:

[0035] S101. Under the condition of relatively stable operating load, record the relevant operating parameters of FGD, and start the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com