Aquagel with high water absorbing capacity and preparation method thereof

A hydrogel and high water absorption technology, applied in the field of polymer synthesis and modification, can solve the problems of difficult processing and low water absorption, and achieve the effects of high water absorption, improved compatibility, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

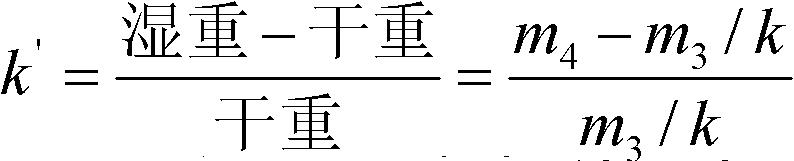

Method used

Image

Examples

Embodiment 1

[0044] In a 250ml four-necked flask, add 60g of water and 4.8g of polyvinyl alcohol (PVA-124, the degree of polymerization is 2450, Shanghai Aladdin Company), start mechanical stirring, the time of nitrogen is 30min, and heat up to 80°C , add 1 / 5 amount of ammonium persulfate (ie 0.0338g, the total amount is 0.169g), 3.09g-2-hydroxyethyl methacrylate and 1.71g acrylic acid, then add 1 / 5 amount of persulfuric acid at intervals of 0.5h Ammonium (ie 0.0338 g). After reacting for 1.5h (1 / 5 amount of ammonium persulfate was added 3 times, totaling 0.1014g), 30g of water, N,N'-methylenebisacrylamide (0.185g), 14.4g of acrylic acid (neutralized 0.7) and the remaining ammonium persulfate (ie 0.0676g), continue the reaction at 80°C for 2.5h, raise the temperature to 85°C, keep it warm for 1h and then lower it to 25°C to obtain a high water absorption hydrogel product.

Embodiment 2

[0046] In a 250ml four-neck flask, add 60g of water and 4.8g of polyvinyl alcohol (PVA-124, the degree of polymerization is 2450, Shanghai Aladdin Co., Ltd.), start the mechanical stirring, the time of nitrogen is 30min, and heat up to 70°C , add 1 / 5 amount of ammonium persulfate (ie 0.0186g, the total amount is 0.093g), 3.09g-2-hydroxyethyl methacrylate and 1.71g acrylic acid, and then add 1 / 5 amount of persulfuric acid at intervals of 0.5h Ammonium (ie 0.0186 g). After reacting for 1.5h (1 / 5 amount of ammonium persulfate was added 3 times, totaling 0.0558g), 20g of water, N,N'-methylenebisacrylamide (0.0822g), 6.4g of acrylic acid (neutralized 0.7) and the remaining ammonium persulfate (ie 0.0372g), continue the reaction at 70°C for 2.5h, raise the temperature to 95°C, keep it warm for 0.5h and then lower it to 15°C to obtain a high water absorption hydrogel product.

Embodiment 3

[0048] In a 250ml four-necked flask, add 60g of water and 4.8g of polyvinyl alcohol (PVA-124, the degree of polymerization is 2450, Shanghai Aladdin Co., Ltd.), start the mechanical stirring, the time of nitrogen is 30min, and heat up to 75°C , add 1 / 5 amount of ammonium persulfate (ie 0.0248g, the total amount is 0.124g), 3.09g 2-hydroxyethyl methacrylate and 1.71g acrylic acid, then add 1 / 5 amount of persulfuric acid at intervals of 0.5h Ammonium (ie 0.0248g). After reacting for 1.5h, add 25g of water, N,N`-methylenebisacrylamide (0.123g), 9.6g of acrylic acid (0.7 in neutralization degree) and the remaining ammonium persulfate (0.0496g), at 75°C Continue to react for 3 hours, raise the temperature to 85°C, keep it warm for 1 hour and then lower it to 35°C to obtain a high water absorption hydrogel product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com