Sealant

A technology of sealant and curing agent, applied in the field of sealant, can solve the problems of low storage stability, complicated preparation process and high production cost, and achieve the effects of simple process, easy storage and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

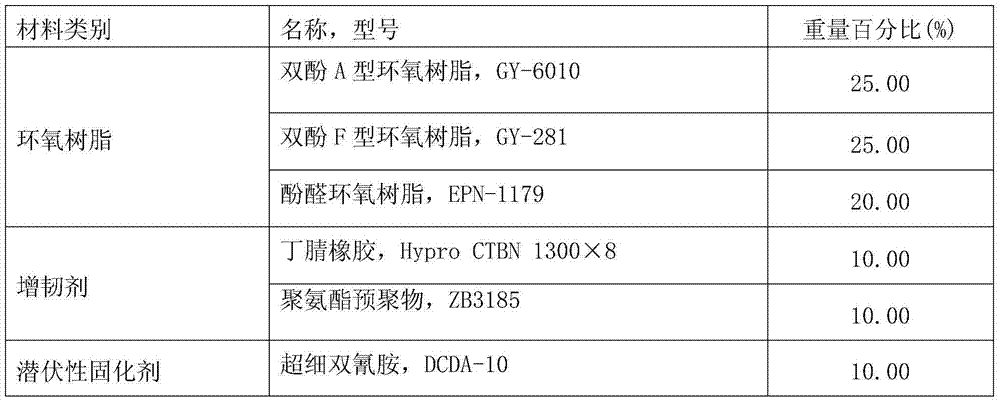

[0040] Sealant, its each component and corresponding weight percent are as shown in Table 1:

[0041] Table I

[0042]

[0043] The preparation method of sealant, concrete steps are as follows:

[0044] a. Add epoxy resin and toughening agent into the double planetary dynamic mixer according to the weight percentage stated in Table 1, control the temperature of the material in the mixer within the range of 80 ° C, stir at high speed for 80 minutes, and make the epoxy resin and toughening agent The toughening agent reacts, and the epoxy resin is modified into a toughened epoxy resin.

[0045] b. After the above reaction is sufficient, reduce the temperature of the reaction product in the double planetary mixer to 20°C, and add the curing agent according to the weight percentage in Table 1, and continue to stir for 45 minutes to make the curing agent and the reaction product uniform mix.

[0046] c. Take the above mixture out of the double planetary power mixer, and grind ...

Embodiment 2

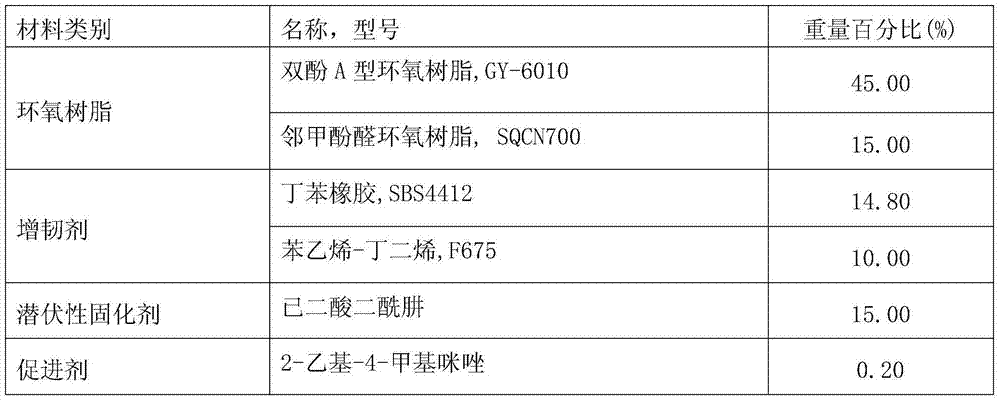

[0049] Sealant, its each component and corresponding weight percent are as shown in table two:

[0050] Table II

[0051]

[0052] The preparation method of sealant, concrete steps are as follows:

[0053] a. Add epoxy resin and toughening agent into the double planetary dynamic mixer according to the weight percentage stated in Table 2, control the temperature of the material in the mixer within the range of 100°C, and stir at high speed for 50 minutes to make the epoxy resin and toughening agent The toughening agent reacts, and the epoxy resin is modified into a toughened epoxy resin.

[0054] b. After the above reaction is sufficient, lower the temperature of the reaction product in the double planetary mixer to 30°C, and add the curing agent and the accelerator according to the weight percentage in Table 2, and continue to stir for 20 minutes to be uniform with the reaction product. mix.

[0055] c. Take the above mixture out of the double planetary power mixer, and ...

Embodiment 3

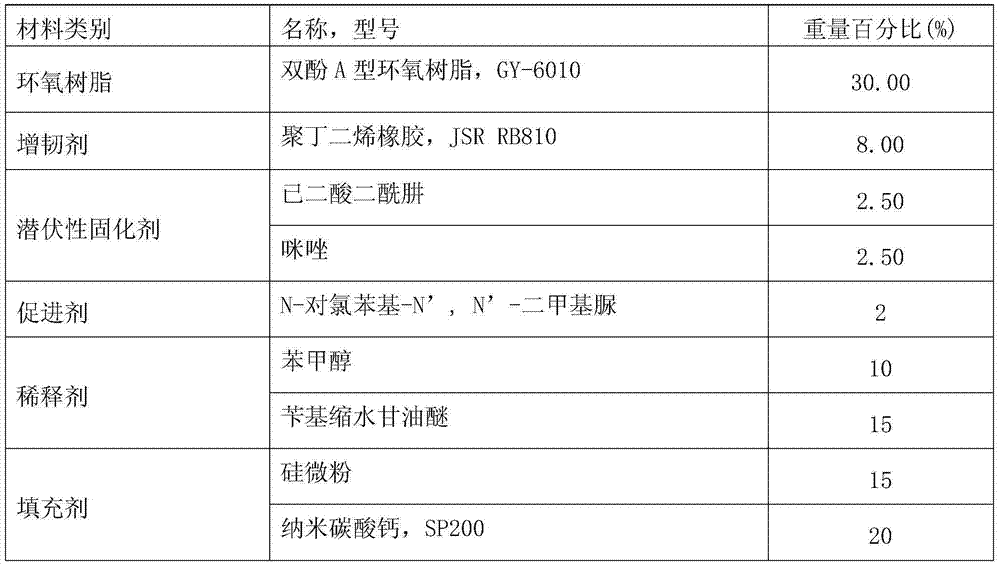

[0058] Sealant, its each component and corresponding weight percent are as shown in table three:

[0059] Table three

[0060]

[0061] The preparation method of sealant, concrete steps are as follows:

[0062] a. Add epoxy resin, toughening agent and filler into the double planetary dynamic mixer according to the weight percentage stated in Table 3, control the temperature of the material in the mixer within the range of 90°C, and stir at high speed for 60 minutes to make the epoxy The resin reacts with the toughening agent, and the epoxy resin is modified into a toughened epoxy resin, which is thoroughly mixed with the filler. During the stirring process, the viscosity of the mixture is adjusted by adding a diluent so that the viscosity of the mixture is not greater than 50,000 centipoise.

[0063] b. After the above reaction is sufficient, reduce the temperature of the reaction product in the double planetary dynamic mixer to 40°C, and add the curing agent and accelera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com