Application of copper tungstate and preparation method of copper tungstate gas sensor

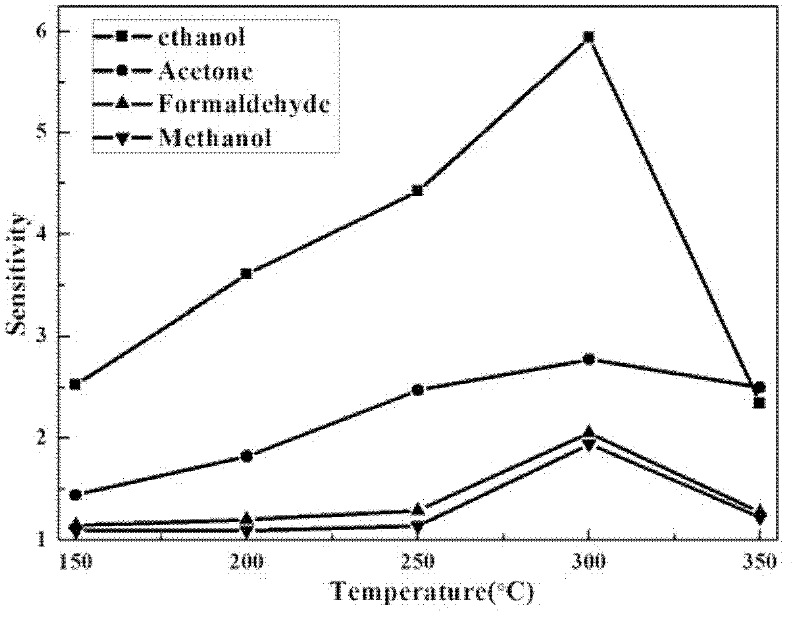

A gas sensor and gas sensing technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., to achieve good selectivity, simple preparation process, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] CuWO 4 The preparation method of gas sensor comprises the steps:

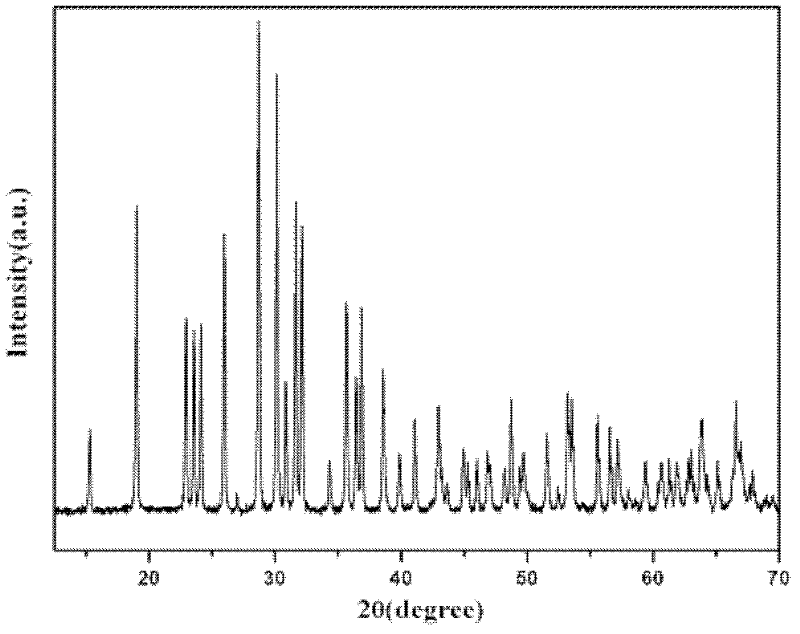

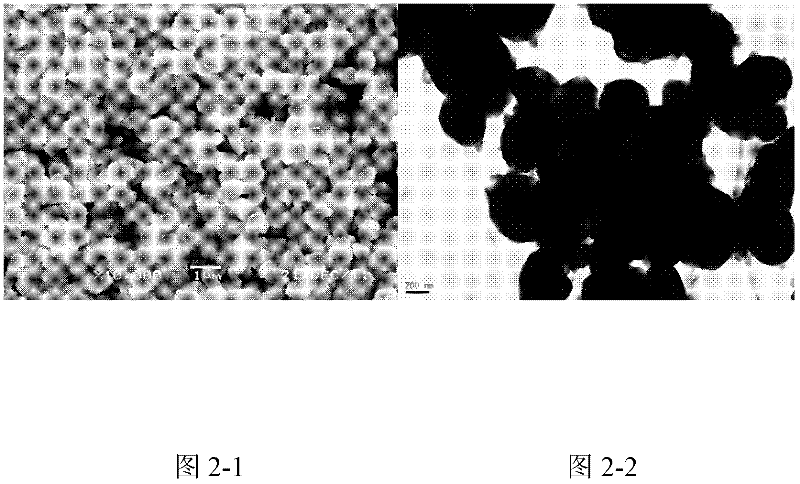

[0056] (1) CuWO 4 Gas-sensitive material preparation: first weigh 0.01mol copper sulfate (CuSO 4 ·5H 2 O) Add to 50ml deionized water and ultrasonically dissolve it for 10 minutes, weigh 0.01mol sodium tungstate (Na 2 WO 4 2H 2 O) Add it to 50ml deionized water and ultrasonically dissolve it for 10 minutes; then mix the above-mentioned copper salt solution and tungsten salt solution to obtain a mixed solution, and control the molar ratio of copper to tungsten to be 1:1; secondly, place the mixed solution at 60° C. React under the same conditions for 6 hours; after the reaction is completed, cool to room temperature, wash the product repeatedly with deionized water 3 times, and dry at 80°C for 6 hours to obtain the precursor; finally, roast the precursor at 600°C for 6h to obtain 300-800nm CuWO 4 powder.

[0057] (2) the CuWO described in step (2) 4 The powder is fully mixed with the terpineol s...

Embodiment 2

[0064] CuWO 4 The preparation method of gas sensor comprises the steps:

[0065] (1) CuWO 4 Gas-sensitive material preparation: first weigh 0.01mol copper sulfate (CuSO 4 ·5H 2 O) Add to 50ml deionized water and ultrasonically dissolve it for 10 minutes, weigh 0.01mol sodium tungstate (Na 2 WO 4 2H 2 O) Add it to 50ml deionized water and ultrasonically dissolve it for 10 minutes; then mix the above-mentioned copper solution and tungsten solution to obtain a mixed solution, and control the molar ratio of copper to tungsten to be 1:1; secondly, put the mixed solution at 60°C React for 12 hours; after the reaction is completed, cool to room temperature, wash the product repeatedly with deionized water three times, and dry at 80°C for 6 hours to obtain the precursor; finally, roast the precursor at 400°C for 12 hours to obtain 40-120nm CuWO 4 gas sensitive material.

[0066] (2) the CuWO described in step (2) 4 The material is fully mixed with the terpineol solution of met...

Embodiment 3

[0071] CuWO 4 The preparation method of gas sensor comprises the steps:

[0072] (1) CuWO 4 Gas-sensitive material preparation: first weigh 0.01mol copper sulfate (CuSO 4 ·5H2 O) Add to 50ml deionized water and ultrasonically dissolve it for 10 minutes, weigh 0.01mol sodium tungstate (Na 2 WO 4 2H 2 O) Add it to 50ml deionized water and ultrasonically dissolve it for 10 minutes; then mix the above-mentioned copper solution and tungsten solution to obtain a mixed solution, and control the molar ratio of copper to tungsten to be 1:1; secondly, put the mixed solution at 60°C React for 1 hour; after the reaction is completed, cool to room temperature, wash the product repeatedly with deionized water 3 times, and dry at 80°C for 6 hours to obtain the precursor; finally, the precursor is roasted at 800°C for 1 hour to obtain 2-3 μm CuWO 4 gas sensitive material.

[0073] (2) the CuWO described in step (2) 4 The material is fully mixed with the terpineol solution of methyl cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com