Automatic temperature control system for heat treatment and using method thereof

A technology of temperature control system and monitoring system, applied in heat treatment process control, control/regulation system, humidity control and other directions, can solve the problems of long heating time, difficult temperature measurement, unintuitiveness, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

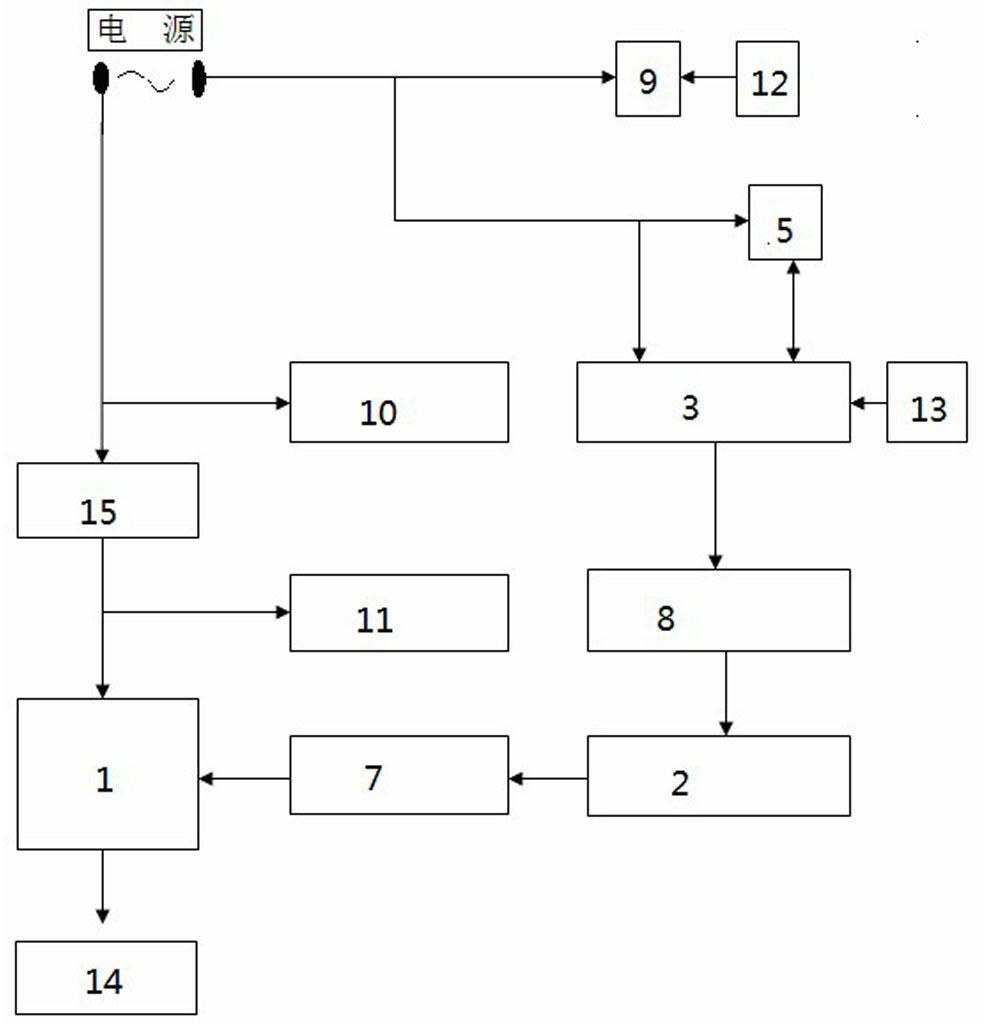

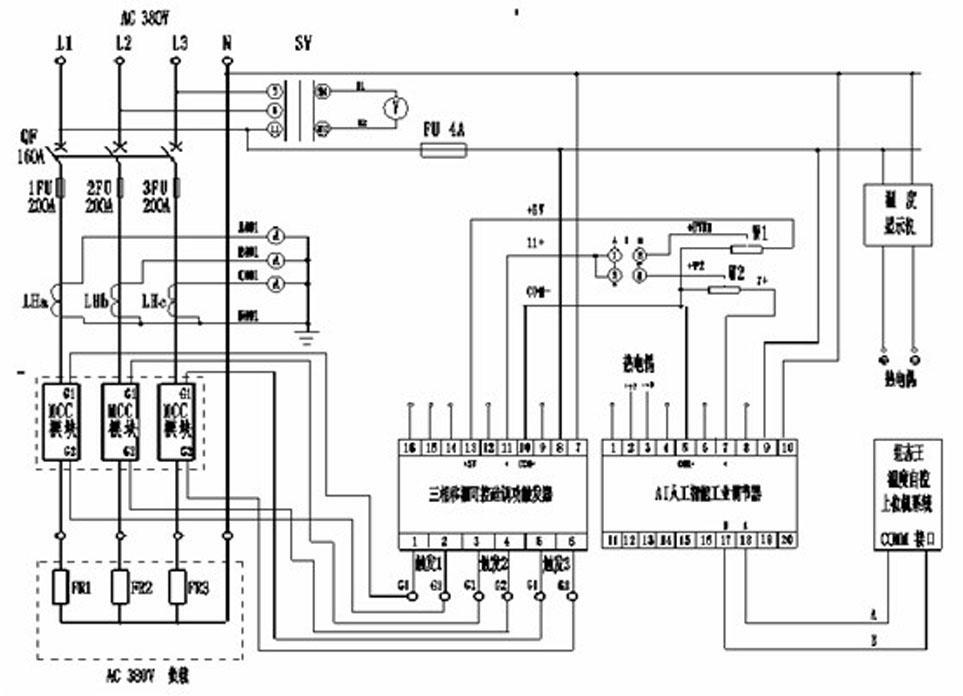

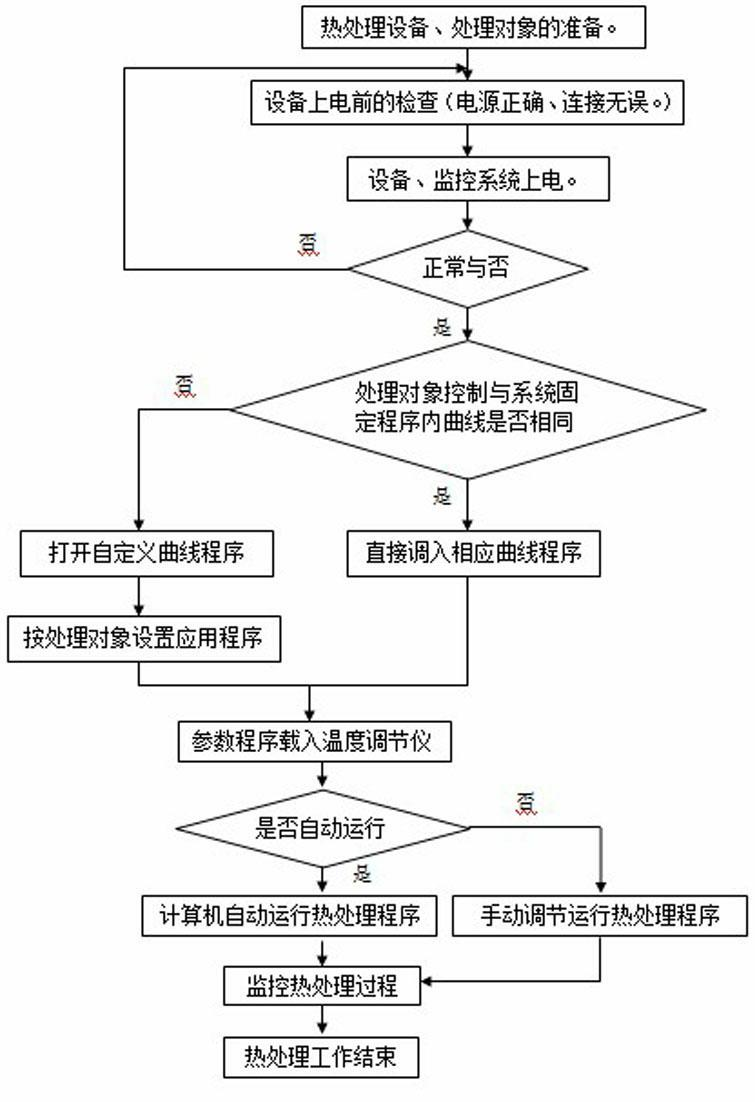

Method used

Image

Examples

Embodiment 1

[0046] 3# vaporizer in a chemical plant

[0047] The first step, the equipment arrives at the site. First, according to the thickness of the weld seam: 50mm; the length of the single-sided weld seam: 3×3.14=9.42m, heat treatment on both sides of the weld seam, determine the capacity of the working power supply required for heat treatment, and connect the power supply to Heat treatment equipment; K graduation number thermocouple 12 and K graduated thermocouples 13 is fixed on both sides of the weld, and the load 14 is a crawler-type ceramic electric heater. Fix the load 14 on the specific part that needs to be heated, and connect the lead wires of the crawler-type ceramic electric heater. The power of the crawler-type ceramic electric heater is reasonable. Distribute the load of each phase and try to balance the load of each phase;

[0048] The second step is to start the heat treatment operation program. According to the required heat treatment workpiece and the requiremen...

Embodiment 2

[0053] The body of a 120,000-ton sulfuric acid waste heat boiler in a chemical plant

[0054] The first step, the equipment arrives at the site, first according to the thickness of the weld seam: 30mm, heat treatment on one side of the weld seam, determine the capacity of the working power supply required for heat treatment, and connect the power supply to the heat treatment equipment; K graduation number thermocouple 12 and K graduated thermocouples 13 is fixed on the edge of the weld seam, the load 14 is a rope-shaped ceramic electric heater, the load 14 is fixed on the weld seam, the lead wire of the load 14 is connected, and the load of each phase is reasonably distributed according to the power of the load 14, so that each phase load balance;

[0055] The second step is to start the heat treatment operation program, and set the process parameters according to the requirements through the self-defined program. The temperature rise slope requirement: 400°C or more is not...

Embodiment 3

[0060] The main steam pipeline of CDQ power station in a coking plant

[0061] The first step, the equipment arrives at the site, first according to the material of the required heat treatment test piece: 15CrMo; specifications: seamless steel pipe ф273×11, seamless steel pipe ф219×9, elbow D250, elbow 200, size head 273×219, Determine the capacity of the working power supply required for heat treatment, and connect the power supply to the heat treatment equipment; K graduation number thermocouple 12 and K graduated thermocouples 13 is fixed next to the heating workpiece, the load 14 is fixed on the specific part that needs to be heated, the lead wire of the load 14 is connected, the load of each phase is reasonably distributed according to the power of the load 14, and the load of each phase is balanced as much as possible;

[0062] The second step is to start the heat treatment operation program, and set the parameters according to the required heat treatment workpiece an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com