Dynamic flow heater

一种加热器、加热装置的技术,应用在紧凑的流体加热器,连续流动的加热器领域,能够解决比率大、冷的芯子流动等问题,达到有利温度控制特征、小空载时间和/或时间常数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

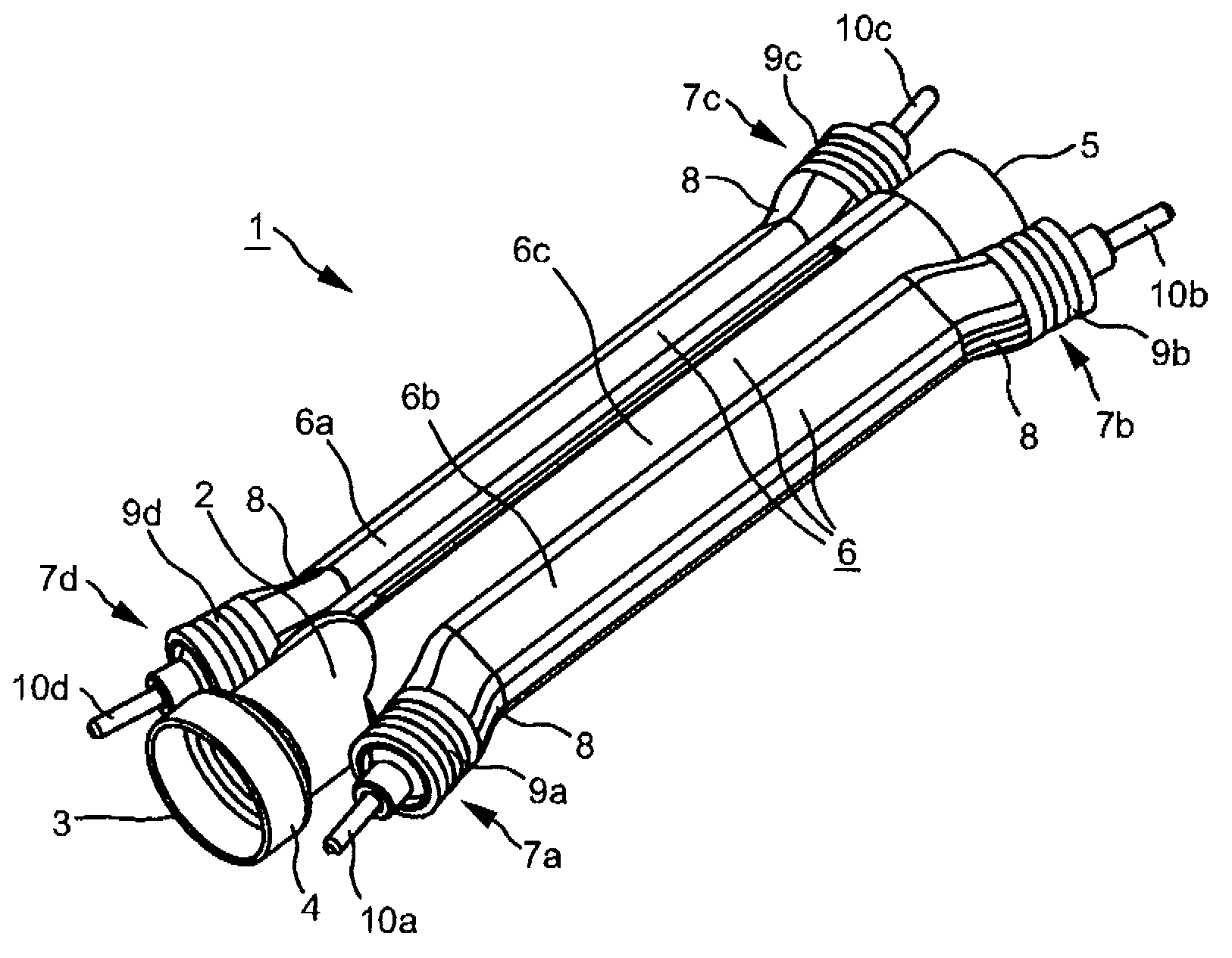

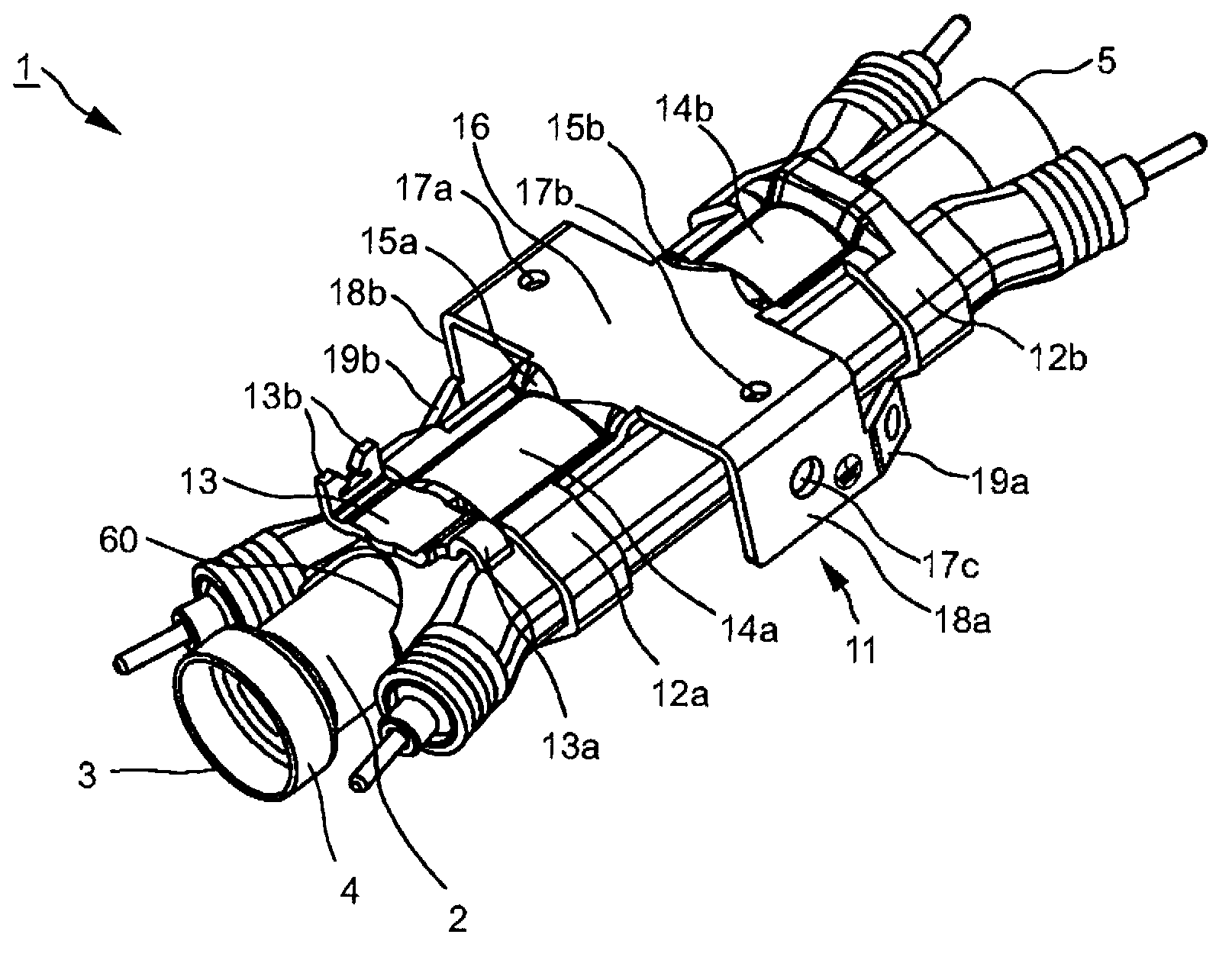

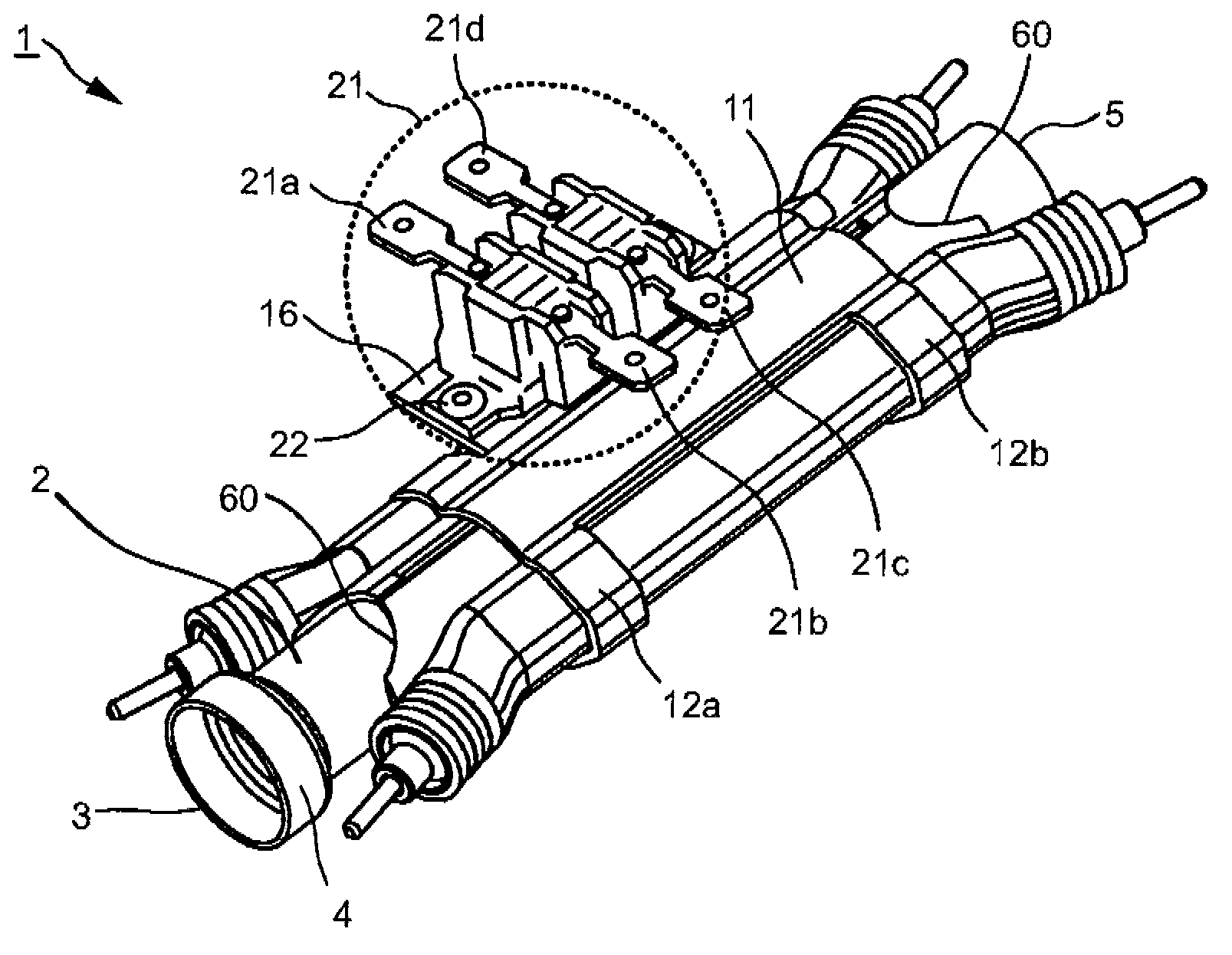

[0076] figure 1 It shows that the basic elements of the fluid connector 1 of the present invention, the metal pipe 2 and the heating device 6, the heating device 6 includes two identical tubular heating elements 6a, 6b and a heat conducting device 6c.

[0077] The metal pipe 2 has an opening 3 in a widened first end portion 4, and the widened first end portion 4 has a cross-sectional enlarged portion compared with other parts of the metal pipe. At the end 5 of the metal pipe 2 opposite to the widened end 4, a sealing plug or end cap 50 can be provided (see Figure 4 , 5, 9), to airtightly and pressure-tightly seal the end.

[0078] in figure 1 The heating device 6 shown in FIG. 6 includes tubular heating elements 6a and 6b and a heat conduction device implemented as a heat conduction plate 6c. The heat conduction plate 6c completely surrounds the metal pipe 2 in the circumferential direction, and the tubular heating elements 6a and 6b are equally spaced along the circumferential di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com