Preparation method of rare earth doped zinc oxide nanowire for gas sensor

A zinc oxide nanowire and gas sensor technology, applied in the field of preparation of rare earth doped zinc oxide nanowires, can solve the problems of high cost, toxicity and price, and achieve the effects of low cost, easy regulation and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 4 g of sodium hydroxide and place it in a three-necked flask, add 50 ml of deionized water, and add 2 ml of triethanolamine to the solution; weigh 15 g of zinc nitrate hexahydrate, add 50 ml of deionized water to make zinc nitrate Aqueous solution, weigh 1 g of dysprosium nitrate pentahydrate, and place it in the zinc nitrate solution; heat the three-necked flask to 80 °C, and after about 20 minutes, inject the zinc-rare earth precursor composite solution, and continue to maintain the temperature for about 30 minutes after injection. The sample was centrifuged to obtain a white powder. Dry it in a drying oven at 50° C. to obtain rare earth-doped zinc oxide nanowires.

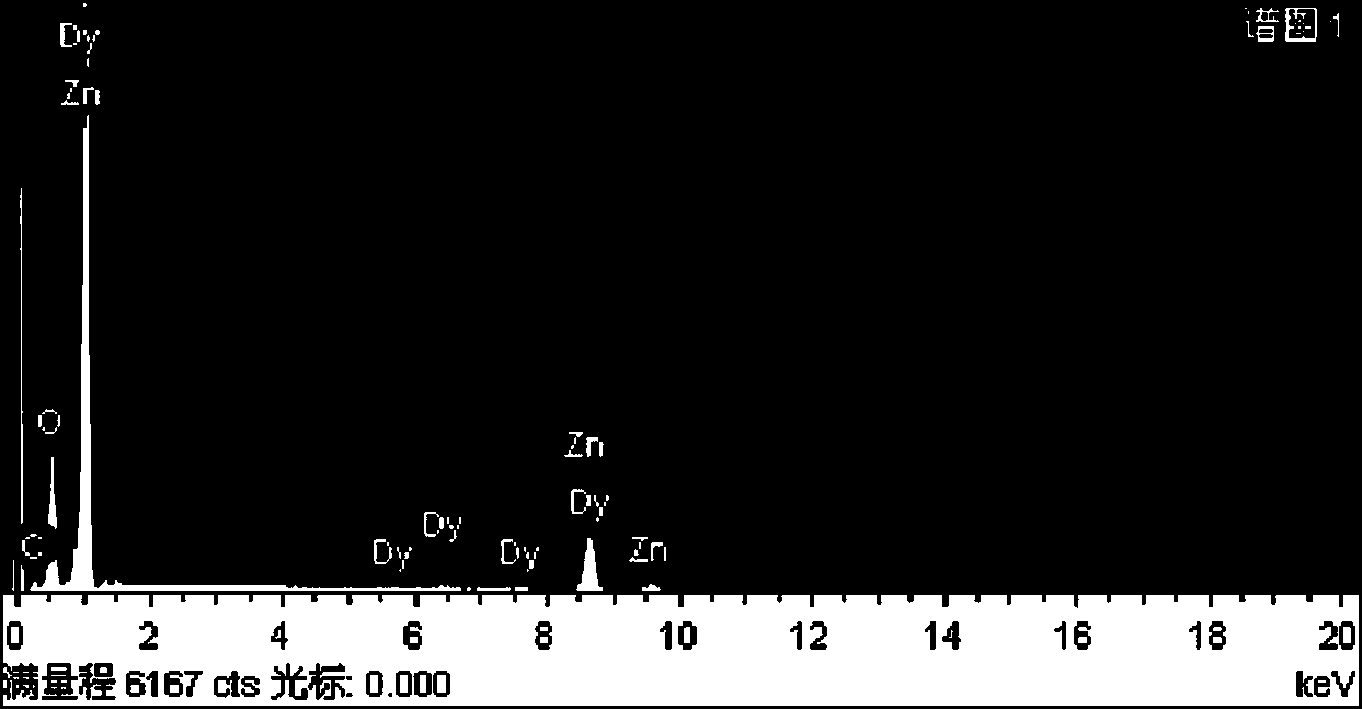

[0025] figure 1 , figure 2 The SEM images and EDS energy spectrum images of the dysprosium-doped zinc oxide nanowires prepared in this example are given respectively. It can be seen from the SEM image that the size distribution of dysprosium-doped zinc oxide nanowires is uniform and the diameter...

Embodiment 2

[0027] Weigh 4 g of sodium hydroxide and place it in a three-necked flask, add 50 ml of deionized water, and add 2 ml of diethanolamine to the solution; weigh 14.3 g of zinc sulfate heptahydrate, add 50 ml of deionized water to make zinc sulfate aqueous solution, weigh 1 g of dysprosium nitrate pentahydrate, and place it in zinc sulfate solution; heat the three-necked bottle to 80 o C. After about 20 minutes, inject the zinc-rare earth precursor composite solution, continue to maintain the temperature for about 30 minutes after injection, and centrifuge the sample to obtain a white powder. at 50 o Dry in a drying oven at C to obtain rare earth-doped zinc oxide nanowires.

Embodiment 3

[0029] Weigh 2.8 g of potassium hydroxide and place it in a three-necked flask, add 50 ml of deionized water, and add 3 ml of diethanolamine to the solution; weigh 14.3 g of zinc sulfate heptahydrate, add 50 ml of deionized water to make zinc sulfate As an aqueous solution, weigh 1 g of dysprosium nitrate pentahydrate and place it in a zinc sulfate solution; heat the three-necked flask to 80°C, and after about 20 minutes, inject the zinc-rare earth precursor composite solution, and continue to maintain the temperature for about 30 minutes after injection. The sample was centrifuged to obtain a white powder. Dry it in a drying oven at 50° C. to obtain rare earth-doped zinc oxide nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com