Optical fiber with coating resin preheating device

A preheating device and resin-coating technology, which is applied to coatings, optical components, and other household appliances, can solve the problems of not being able to apply high-speed optical fibers, slow heating speed, and poor uniformity, so as to improve the quality of production technology and facilitate maintenance , The effect of reducing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

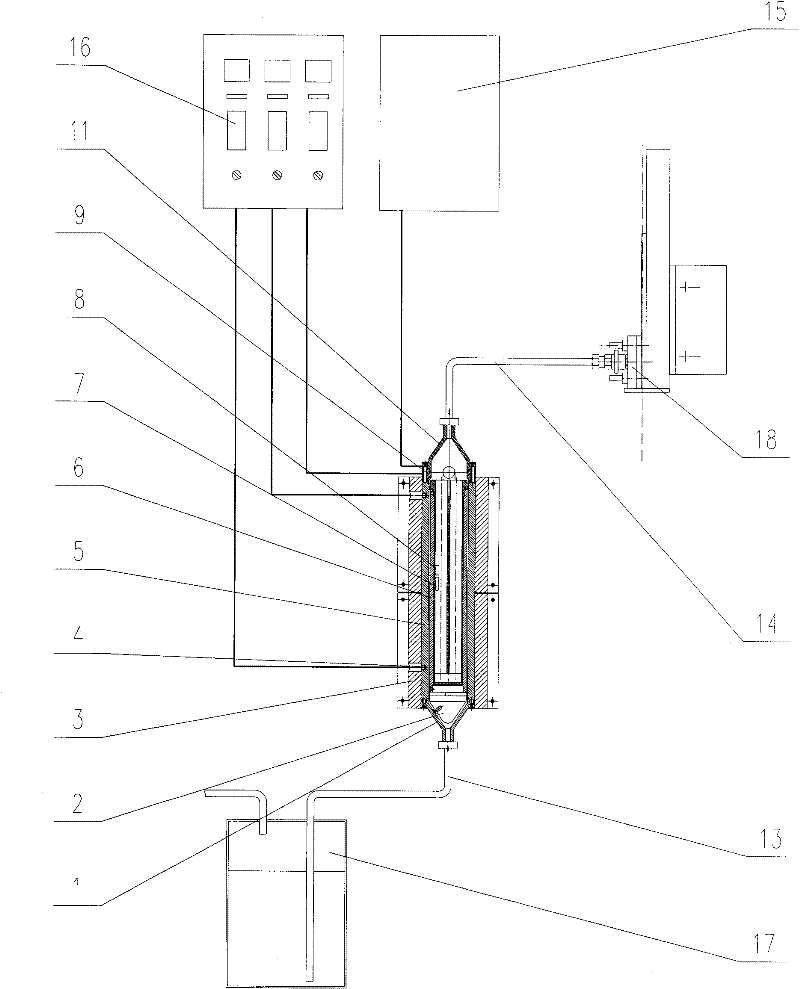

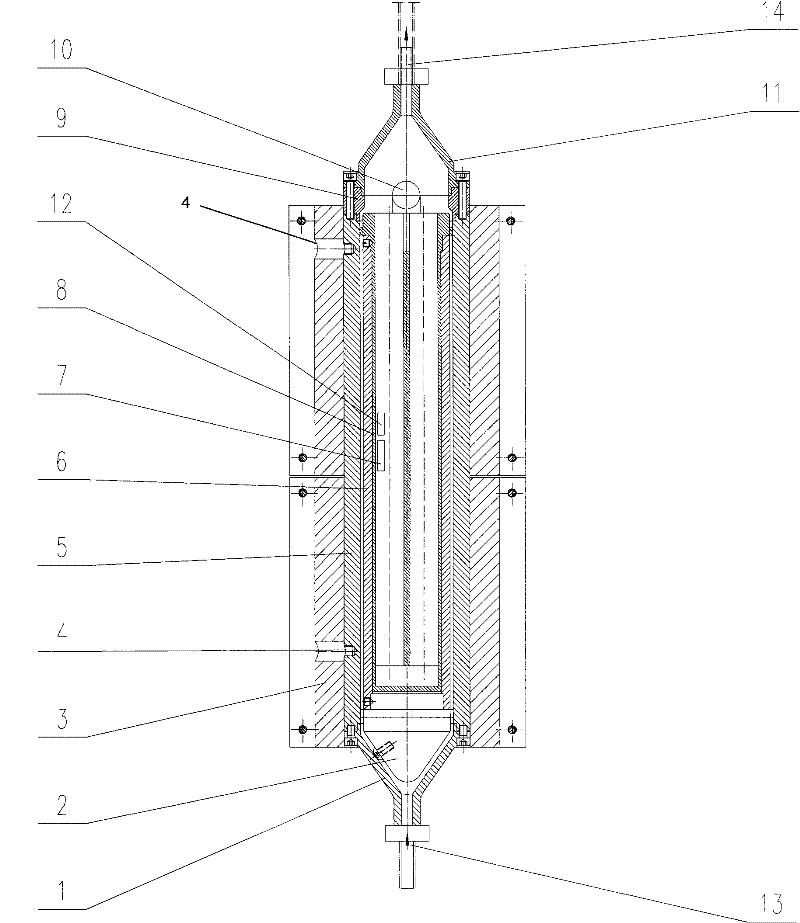

[0028] A preferred embodiment of the present invention is given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0029] Such as figure 1 As shown, the optical fiber of the embodiment of the present invention is equipped with a coating resin preheating device. The inlet end extends into the resin barrel 17 through the input pipeline 13 , and the outlet end is connected with the coating Hafur mold 18 through the output pipeline 14 .

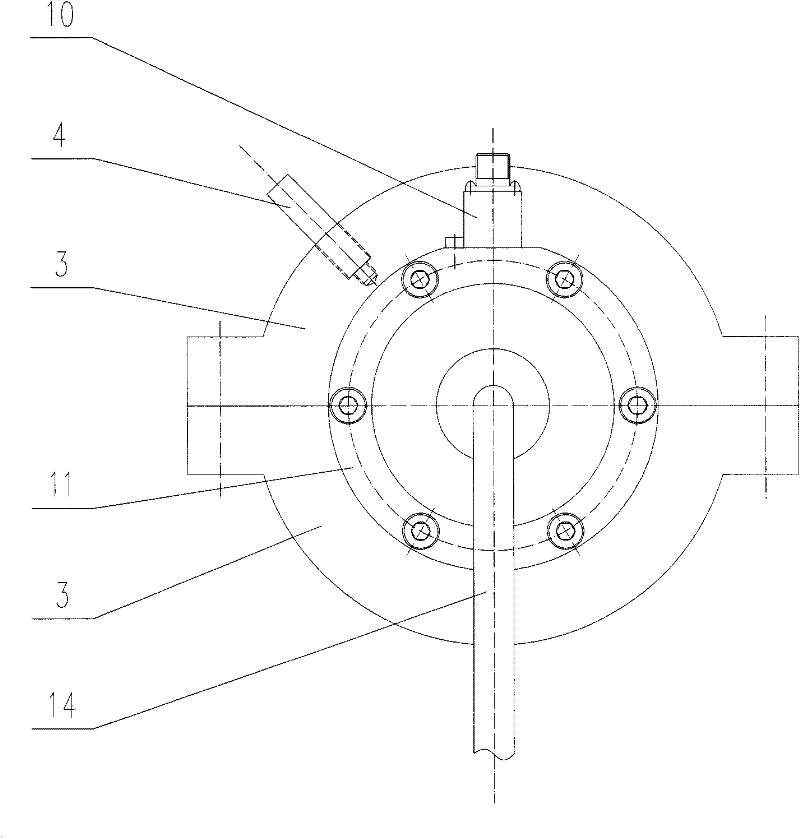

[0030] Such as figure 1 and 2 As shown, in this embodiment, the outer tube 5 is a hollow cylinder ( figure 2 is a sectional view), a cone-shaped flow equalizer 2 is installed at the inlet end of the outer pipe 5, and is fixed with the inlet flange joint 1 by bolts, and the inlet flange joint 1 plays a sealing role. The outer layer electric heater 3 surrounds the outer layer of the outer tube 5, the height is roughly the same as the outer tube 5, and is fixed on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com