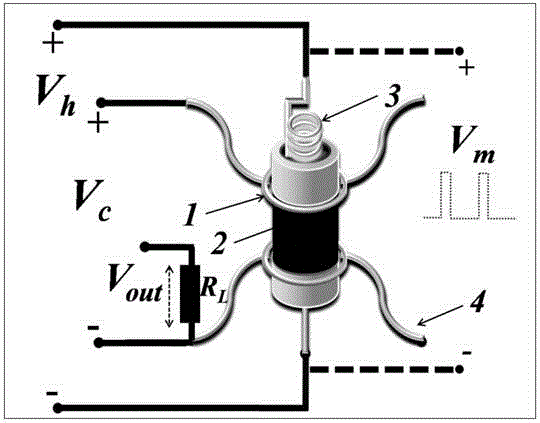

Semiconductor sensor and testing circuit of hydrogen sulfide gas

A semiconductor, hydrogen sulfide technology, applied in the direction of material resistance, can solve the problems of environmental temperature sensitivity and unfavorable detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

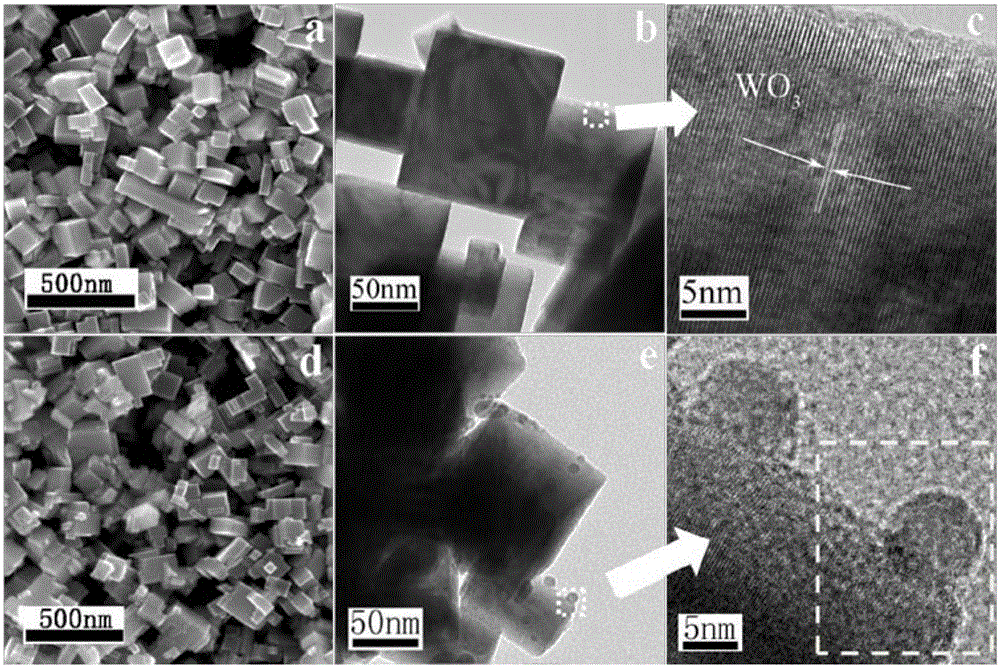

[0033] Weigh 2.1gNa 2 WO 4 ·H 2 O, add 30ml of distilled water, stir well to make it all dissolve. Then use a peristaltic pump to add an equal volume of 2MH dropwise at a rate of 1 rap / min. 2 SO 4, fully stirred, the solution gradually changed from colorless to golden yellow. Take 15ml of the golden-yellow precursor solution, add it into a 25ml reaction kettle, and conduct a hydrothermal reaction at 180°C for 12 hours. Centrifuge, pour off the supernatant, wash with water and ethanol three times respectively, and finally dry at 60°C to obtain a yellow powder, which is a pure-phase tungsten trioxide cube, see figure 1 .

Embodiment 2

[0035] The specific experimental details of the second step of hydrothermal synthesis of tungsten trioxide nano-square and copper oxide particle heterojunction structure for the preparation of the gas-sensitive material for the hydrogen sulfide gas test sensor in the present invention are as follows:

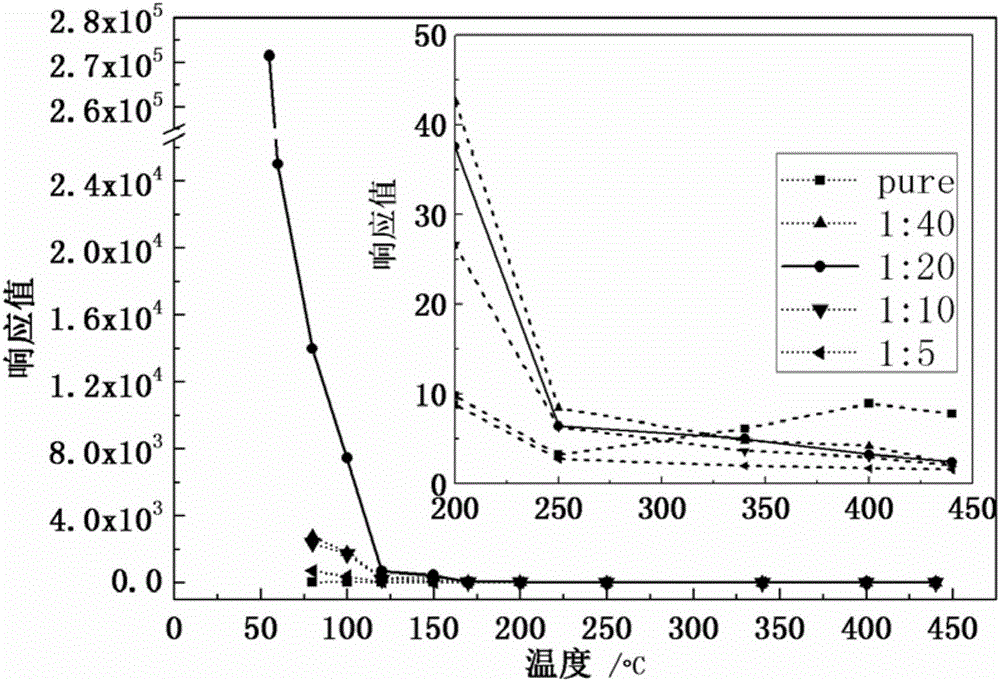

[0036] Weigh 0.232gWO 3 Nano cubes, evenly dispersed in 50ml ethanol, then add 10ml different concentrations of (CH 3 COO) 2 Cu ethanol solution (0.0025M, 0.005M, 0.01M, 0.02M respectively) was stirred thoroughly to make it evenly mixed. Water heating at 140°C for 4h. Centrifuge, discard the supernatant, wash twice with water and ethanol, and finally dry at 60°C to obtain a yellow to brown powder. Finally, calcined at 500°C for 1 hour, and finally obtained WO whose color gradually transitioned from yellow to dark yellow. 3 / CuO composite structure powder (corresponding to pure molar ratio; 100:2.5; 100:5; 100:10; 100:20), see figure 1 , figure 2 .

Embodiment 3

[0038] The details of the second method of the second hydrothermal synthesis of the heterojunction structure of tungsten trioxide nanocubes and copper oxide particles in the present invention are as follows:

[0039] Weigh 5g (CH 3 COO) 2 Cu was dispersed in 50ml of ethanol, mixed evenly, heated in water at 140°C for 4h, washed, and calcined to obtain CuO particle powder. Weigh 15.8, 7.9, 3.95, 1.975mg CuO powder respectively, and then weigh five parts of 2.1gNa 2 WO 4 ·H 2 O, add 30ml of distilled water respectively, stir well to make it all dissolve. Then use a peristaltic pump to add an equal volume of 2MH dropwise at a rate of 1 rap / min. 2 SO 4 , stir well. Take 15ml of the golden-yellow precursor solution, add it into a 25ml reaction kettle, and conduct a hydrothermal reaction at 180°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com