Triethylamine sensor based on MoO3 nano sensitive material as well as preparation method and application thereof

A sensitive material, triethylamine technology, applied in the direction of material resistance, can solve the problems of poor selectivity and other applications, and achieve the effects of good stability, strong reliability, and simple steps in the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

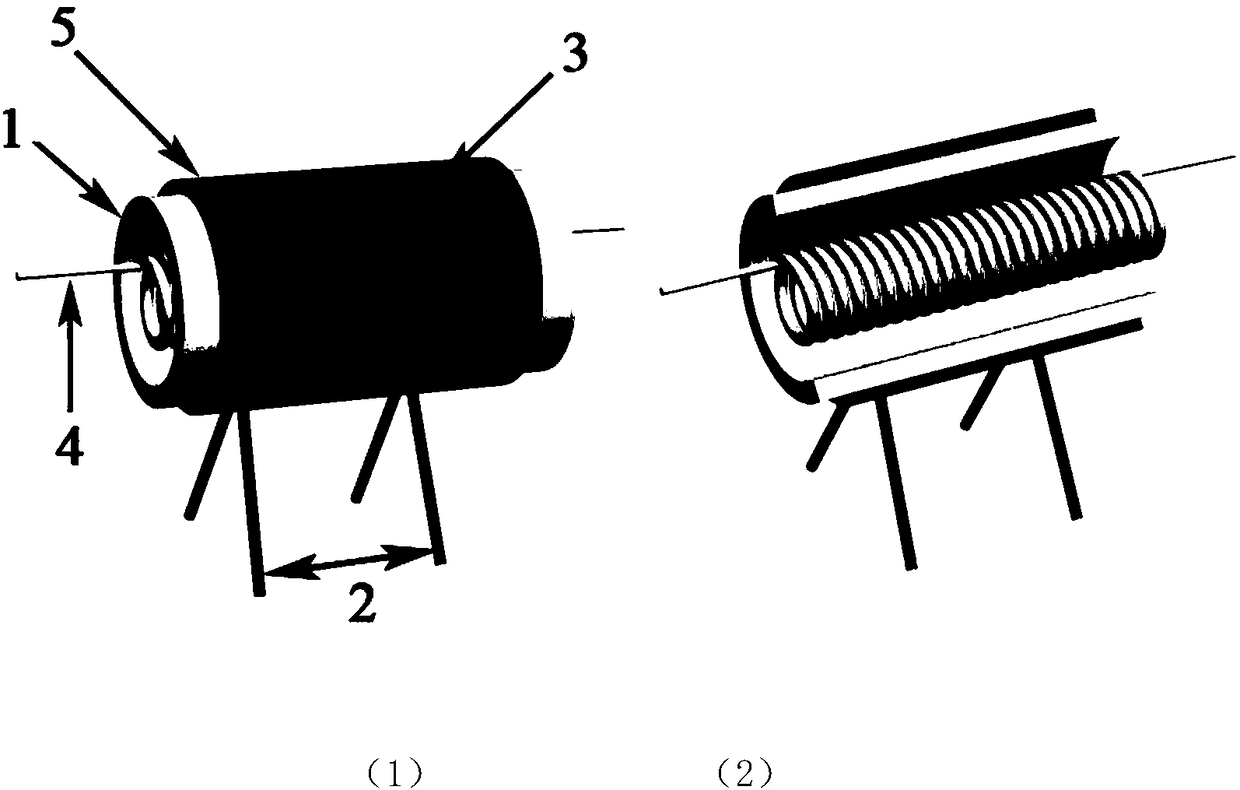

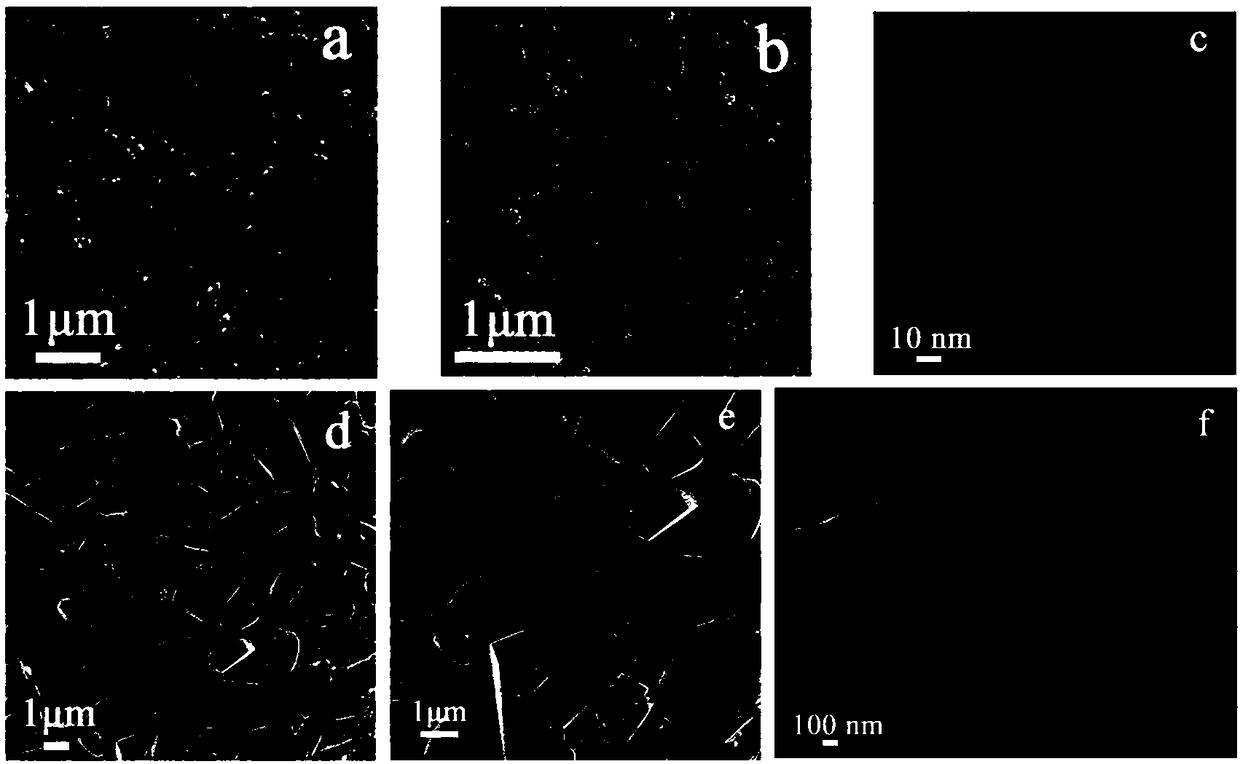

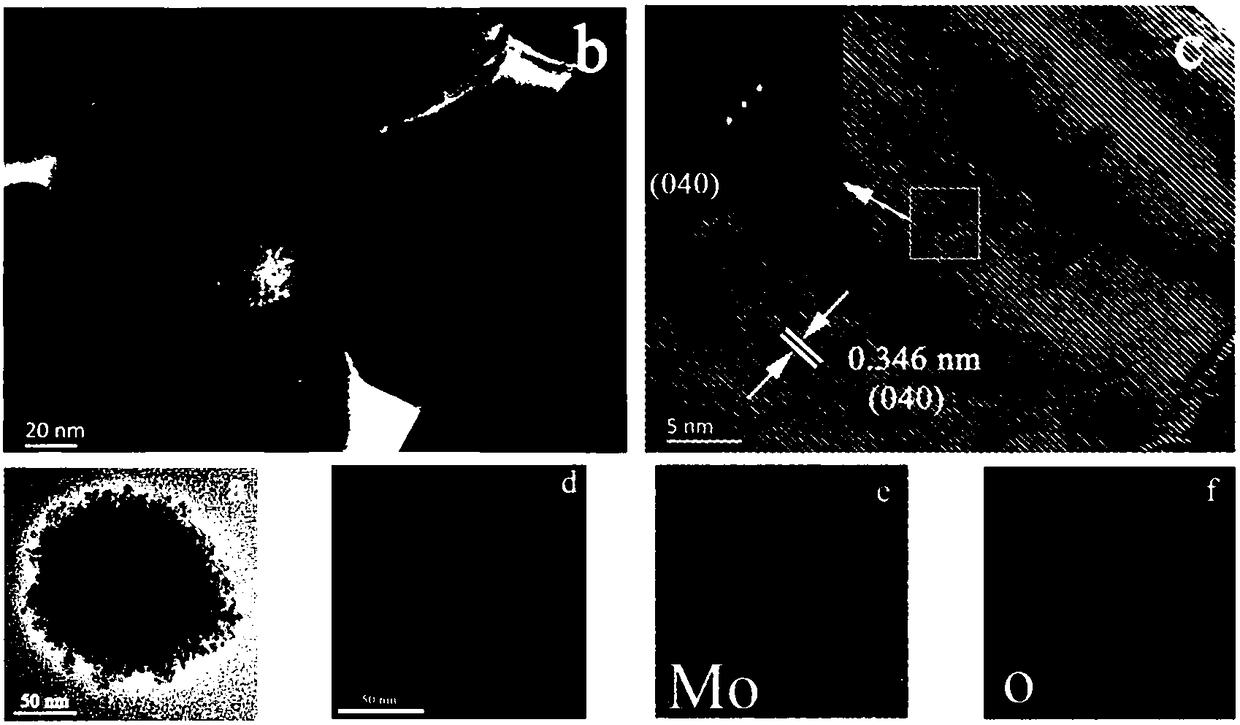

[0033] With MoO 3 Nanosheets are used as sensitive materials to make side-heated triethylamine sensors. The specific manufacturing process:

[0034] First add 0.087g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 30 mL deionized water. After stirring for 20min, 3mL PEG-400 and 3mL concentrated HNO 3 (65%) was dripped into the above solution drop by drop, and continued to stir for 20min;

[0035] 2. Put the above solution into a 50mL hydrothermal kettle, then put it into a hydrothermal oven, and set the oven parameters to 180°C for 24h;

[0036] 3. After the reaction is finished, the obtained product is alternately centrifuged and washed with water and ethanol. The centrifuge parameter is set as 10000r / min, 10min. After centrifugation the product was dried. After drying, the product was calcined at 500° C. for 2 h.

[0037] 4. Take an appropriate amount of prepared nanomaterials and ethanol and mix them uniformly at a mass ratio of 0.3 mg:1 mg to form a slurry. Dip an ...

Embodiment 2

[0042] With MoO 3 Nanosheets are used as sensitive materials to make side-heated triethylamine sensors. The specific manufacturing process:

[0043] First add 0.087g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 30 mL deionized water. After stirring for 20min, 3mL PEG-400 and 3mL concentrated HNO 3 (65%) was dripped into the above solution drop by drop, and continued to stir for 20min;

[0044] 2. Put the above solution into a 50mL hydrothermal kettle, then put it into a hydrothermal oven, and set the oven parameters to 180°C for 24h;

[0045] 3. After the reaction is finished, the obtained product is alternately centrifuged and washed with water and ethanol. The centrifuge parameter is set as 10000r / min, 10min. After centrifugation the product was dried. After drying, the product was calcined at 500° C. for 2 h.

[0046] 4. Take an appropriate amount of prepared nanomaterials and ethanol and mix them uniformly at a mass ratio of 0.3 mg:1 mg to form a slurry. Dip an ...

Embodiment 3

[0051] With MoO 3 Nanosheets are used as sensitive materials to make side-heated triethylamine sensors. The specific manufacturing process:

[0052] First add 0.087g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 30 mL deionized water. After stirring for 20min, 3mL PEG-400 and 3mL concentrated HNO 3 (65%) was dripped into the above solution drop by drop, and continued to stir for 20min;

[0053] 2. Put the above solution into a 50mL hydrothermal kettle, then put it into a hydrothermal oven, and set the oven parameters to 180°C for 24h;

[0054] 3. After the reaction is finished, the obtained product is alternately centrifuged and washed with water and ethanol. The centrifuge parameter is set as 10000r / min, 10min. After centrifugation the product was dried. After drying, the product was calcined at 500° C. for 2 h.

[0055] 4. Take an appropriate amount of prepared nanomaterials and ethanol and mix them uniformly at a mass ratio of 0.3 mg:1 mg to form a slurry. Dip an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com