Preparation method and application of carbon-doped mesoporous metal oxide acetone sensor

A technology of oxides and sensors, which is applied in metal material coating technology, instruments, scientific instruments, etc., can solve the problems of low sensitivity and narrow detection range of gas sensors, and achieve the advantages of avoiding mutual influence, good reliability and large heat capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

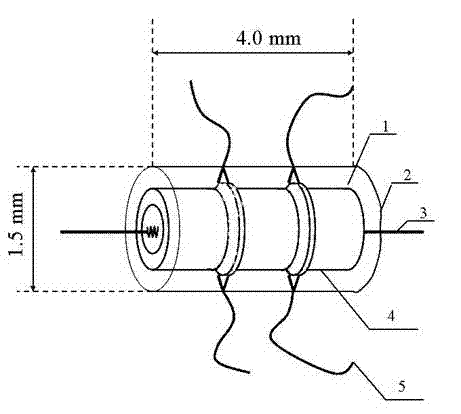

Image

Examples

Embodiment 1

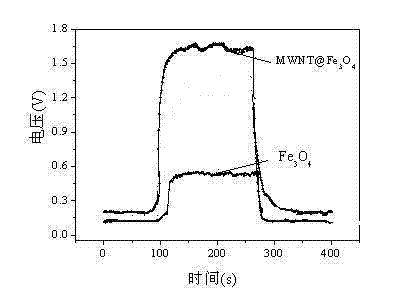

[0035] Example 1: MWNTFe 3 o 4 resolve resolution one

[0036] Pipette 20 mL of ethylene glycol, add 1.1 g FeCl 3 ?6H 2 O, sonicate to dissolve, under magnetic stirring, add 2.8 g of anhydrous sodium acetate and 9.6 mL of anhydrous ethylenediamine, and add multi-walled carbon nanotubes at the same time, stir vigorously for 20 min, and place the mixture in polytetrafluoroethylene In a reaction kettle of ethylene, react at 200°C for 7.0 h, then cool naturally to room temperature, wash with water until the solution is neutral, and dry the solid in a vacuum oven at 50°C for 6.0 h to obtain MWNTFe 3 o 4 ; The diameter of the multi-walled carbon nanotubes is 8 nm, the length is 50 μm, and the purity is greater than 95%; the ethylenediamine is excessive, so that the surface of the prepared mesoporous ferric oxide has amino groups, containing The amount of amino groups is 0.2 μg / mg; multi-walled carbon nanotubes and Fe 3 o 4 The mass ratio is 0.02:1.

Embodiment 2

[0037] Example 2: MWNTFe 3 o 4 resolve resolution two

[0038] Pipette 20 mL of ethylene glycol, add 1.2 g FeCl 3 ?6H 2O, sonicate to dissolve, under magnetic stirring, add 2.9 g of anhydrous sodium acetate and 9.7 mL of anhydrous ethylenediamine, and add multi-walled carbon nanotubes at the same time, stir vigorously for 22 min, and place the mixture in polytetrafluoroethylene In a reaction kettle of ethylene, react at 200°C for 7.5 h, then cool naturally to room temperature, wash with water until the solution is neutral, and dry the solid in a vacuum oven at 55°C for 5.0 h to obtain MWNTFe 3 o 4 The diameter of the multi-walled carbon nanotubes is 12 nm, the length is 50 μm, and the purity is greater than 95%; the ethylenediamine is excessive, so that the surface of the prepared mesoporous ferric oxide has amino groups, and the amino groups contained The amount is 0.10 μg / mg; multi-walled carbon nanotubes and Fe 3 o 4 The mass ratio is 0.04:1.

Embodiment 3

[0039] Example 3: MWNTFe 3 o 4 Synthetic method three

[0040] Pipette 20 mL of ethylene glycol, add 1.1 g FeCl 3 ?6H 2 O, sonicate to dissolve, under magnetic stirring, add 2.9 g of anhydrous sodium acetate and 9.8 mL of anhydrous ethylenediamine, and add multi-walled carbon nanotubes at the same time, stir vigorously for 25 min, and place the mixture in polytetrafluoroethylene In a reaction kettle of ethylene, react at 200°C for 8.0 h, then naturally cool to room temperature, wash with water until the solution is neutral, and dry the solid in a vacuum oven at 60°C for 5.0 h to obtain MWNTFe 3 o 4 The diameter of the multi-walled carbon nanotubes is 10 nm, the length is 50 μm, and the purity is greater than 95%; the ethylenediamine is excessive, so that the surface of the prepared mesoporous ferric oxide has amino groups, and the amino groups contained The amount is 0.15 μg / mg; multi-walled carbon nanotubes and Fe 3 o 4 The mass ratio is 0.1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com