Wall mounting type and floor type electric heating warming stove heater-type light wave electrical heating tube installation structure

A technology of installation structure and electric heating tube, which is applied in the direction of lighting and heating equipment, fluid heaters, etc., can solve the problems of water tank cracks, short life, corrosion breakdown, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

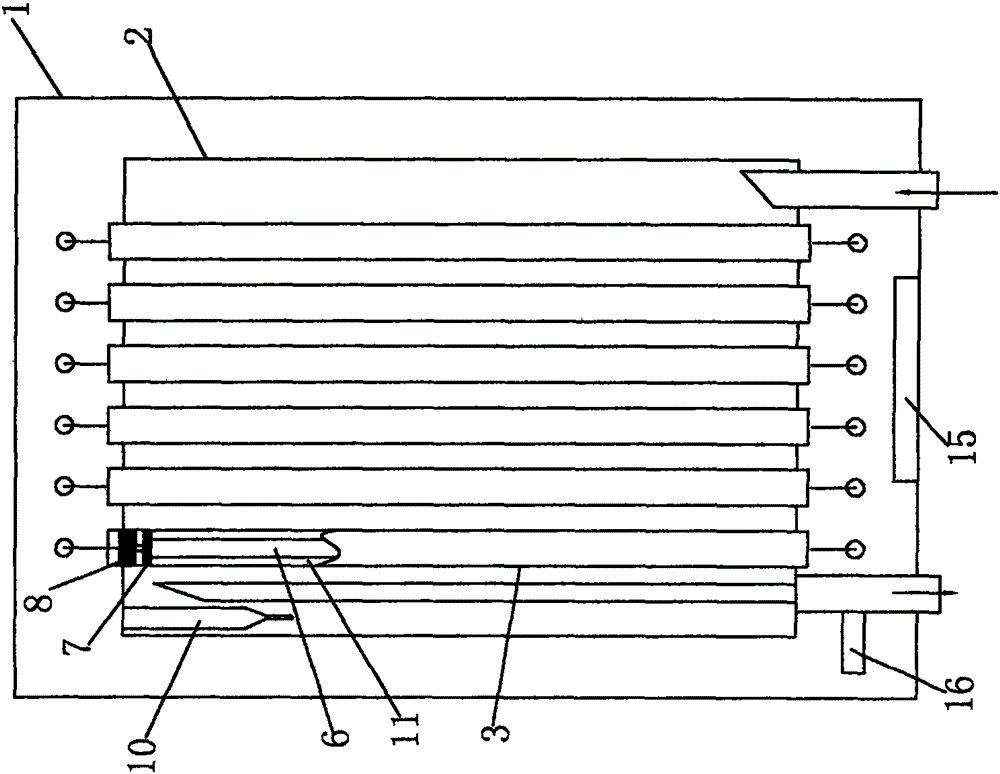

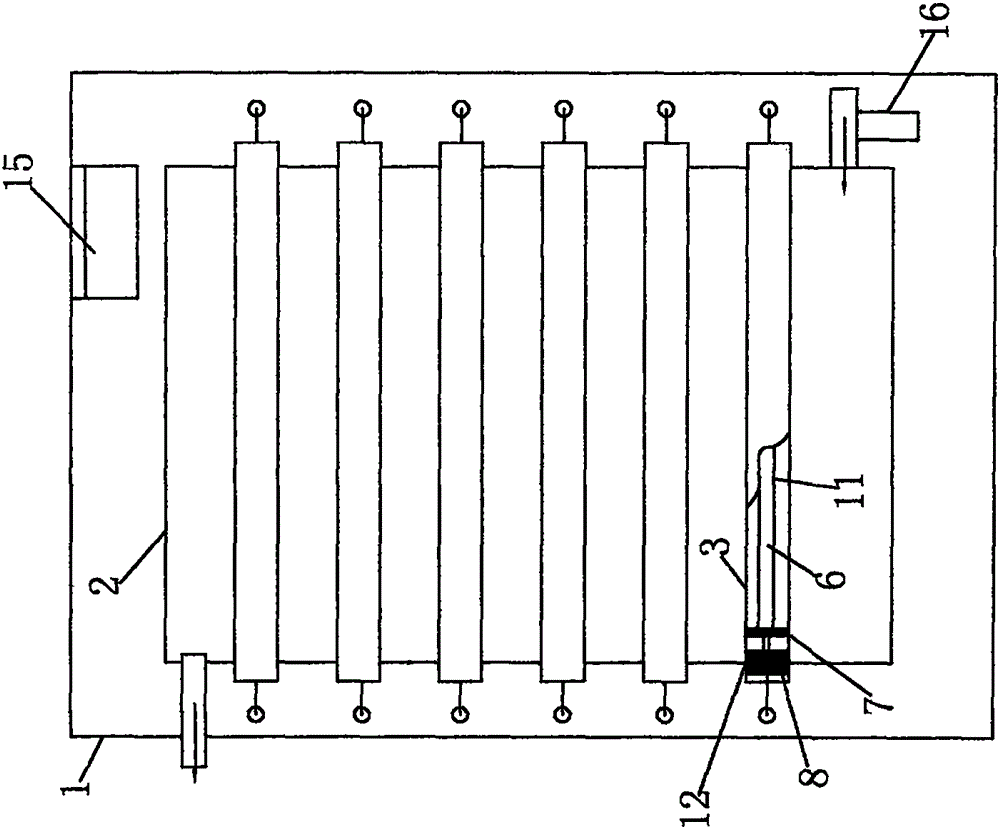

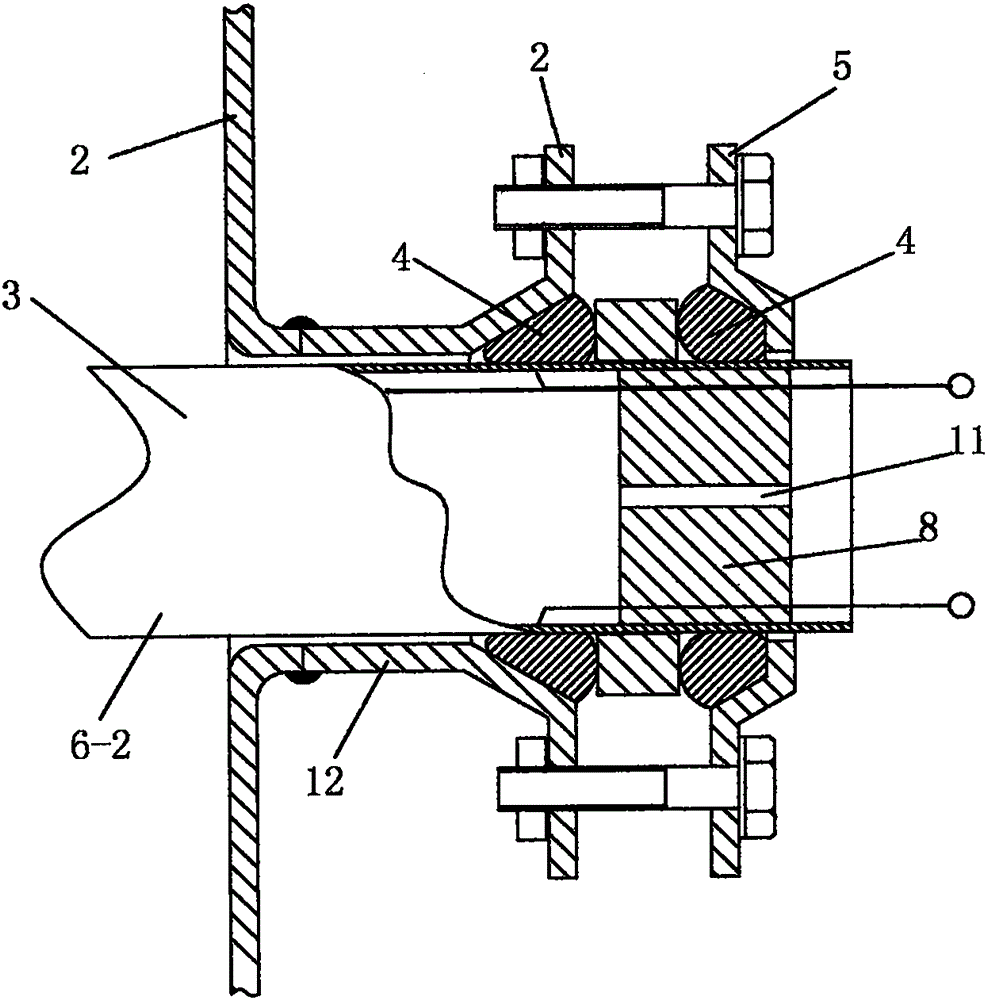

[0021] The following description will be made in conjunction with the accompanying drawings. In the accompanying drawings: shell 1, water tank 2, metal or non-metallic casing 3, seal 4, nut or cover plate 5, electric heating tube 6 (light wave electric heating tube 6-1, semiconductor electric heating tube 6-2), mica sheet 7, non-metallic bracket 8, intermediate glass tube 9, temperature measuring tube 10, air 11, joint with holes, flanges or threads 12, controller 15, pressure relief valve 16.

[0022] figure 1 is a wall-mounted structure, figure 2 It is floor-standing type; directly weld the metal casing 3 on both sides or the upper and lower parts of the water tank, and install the electric heating tube in the casing 3; or weld the joint 12 on the side wall of the water tank, which must be kept concentric to ensure that the installation position of the casing 3 is correct , and the water tank are sealed; the position and number of joints are not limited, and the light-wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com