Preparation method and application of n-p junction type ferrum-copper based oxide gas sensitive element

A gas-sensing element, iron-copper-based technology, which is applied in the field of preparation of n-p junction iron-copper-based oxide gas-sensing elements, can solve the problems of no technical enlightenment, no disclosure, etc., and achieve good synergistic sensitization effect and heat capacity. large, avoid the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

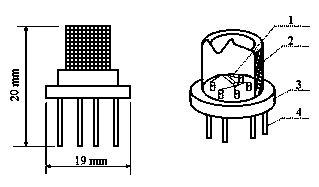

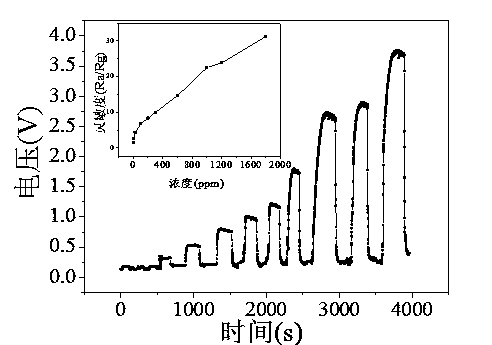

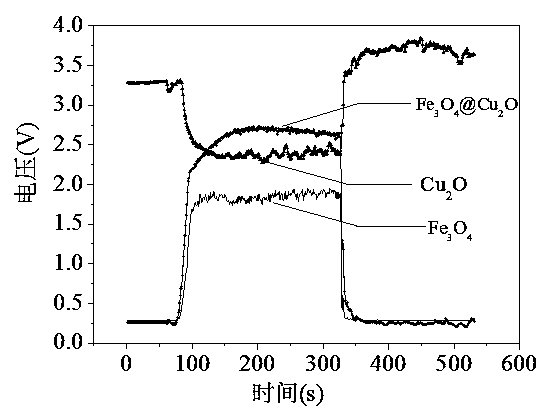

Image

Examples

Embodiment 1

[0034] (1) Preparation of monodisperse mesoporous Fe3O4 nanomaterials: 0.8 g FeCl 3 ?6H 2O was dissolved in 18 mL of ethylene glycol solution to form a transparent solution, then 2.6 g of anhydrous NaAc and 9.0 mL of ethylenediamine were added, the mixture was fully stirred for 32 min, and it was packaged in a polytetrafluoroethylene reactor and heated at 200 After 6.0 h at ℃, cool to room temperature, wash the black solid with water several times until neutral, and dry the solid in a vacuum oven at 50 °C for 8.5 h to obtain monodisperse mesoporous ferric oxide nanoparticles; The ethylenediamine is excessive, and the excess ethylenediamine makes the surface of ferric oxide contain 0.1 μg / mg of amino groups; the pore diameter of the monodisperse mesoporous ferric oxide nanoparticles is 3 nm.

[0035] (2) Preparation of cuprous oxide nanomaterials: 0.5 mL, 0.68 mol / L CuSO 4 and 0.7 g of polyvinylpyrrolidone K30 (PVP K30) were dissolved in 15 mL of ultrapure water, added to a r...

Embodiment 2

[0038] (1) Preparation of monodisperse mesoporous Fe3O4 nanomaterials: 0.9 g FeCl 3 ?6H 2 O was dissolved in 18 mL of ethylene glycol solution to form a transparent solution, then 2.7 g of anhydrous NaAc and 9.2 mL of ethylenediamine were added, the mixture was fully stirred for 33 min, and it was packaged in a polytetrafluoroethylene reactor and heated at 200 After 6.5 h at ℃, cool to room temperature, wash the black solid with water several times until neutral, and dry the solid in a vacuum oven at 50 °C for 9.0 h to obtain monodisperse mesoporous ferric oxide nanoparticles; The ethylenediamine is in excess, and the excess ethylenediamine makes the surface of ferric oxide contain 0.15 μg / mg of amino groups; the pore size of the monodisperse mesoporous ferric oxide nanoparticles is 12 nm.

[0039] (2) Preparation of cuprous oxide nanomaterials: 0.6 mL, 0.68 mol / L CuSO 4 and 0.8 g of polyvinylpyrrolidone K30 (PVP K30) were dissolved in 16 mL of ultrapure water, added to a ro...

Embodiment 3

[0042] (1) Preparation of monodisperse mesoporous iron oxide nanomaterials: 1.0 g FeCl 3 ?6H 2 O was dissolved in 18 mL of ethylene glycol solution to form a transparent solution, then 2.6 g of anhydrous NaAc and 9.4 mL of ethylenediamine were added, the mixture was fully stirred for 33 min, and it was packaged in a polytetrafluoroethylene reactor and heated at 200 After 7.0 h at ℃, cool to room temperature, wash the black solid with water several times until neutral, and dry the solid in a vacuum oven at 50 °C for 9.0 h to obtain monodisperse mesoporous ferric oxide nanoparticles; The ethylenediamine is excessive, and the excess ethylenediamine makes the surface of ferric oxide contain 0.2 μg / mg of amino groups; the pore diameter of the monodisperse mesoporous ferric oxide nanoparticles is 8 nm.

[0043] (2) Preparation of cuprous oxide nanomaterials: 0.7 mL, 0.68 mol / L CuSO 4 and 0.75 g of polyvinylpyrrolidone K30 (PVP K30) were dissolved in 15 mL of ultrapure water, added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com