Winding, stator and motor

A winding and stator technology, applied in the shape/style/structure of motors, winding conductors, electromechanical devices, etc., can solve the problems of high cost, reduce motor efficiency and density, and improve electrical load density and achieve high density. , the effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

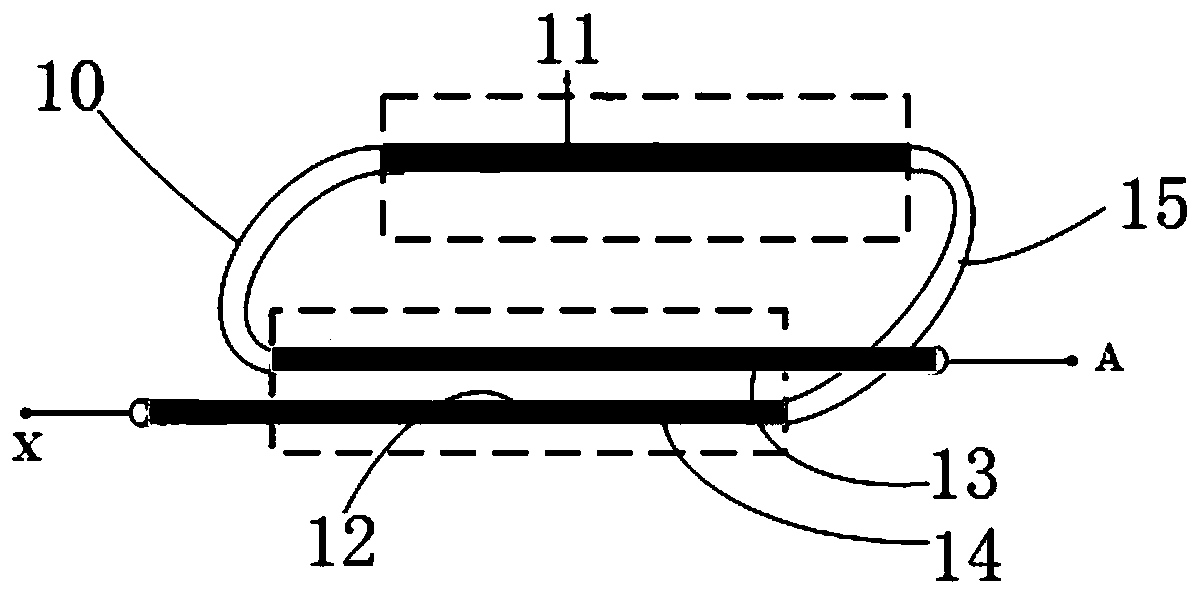

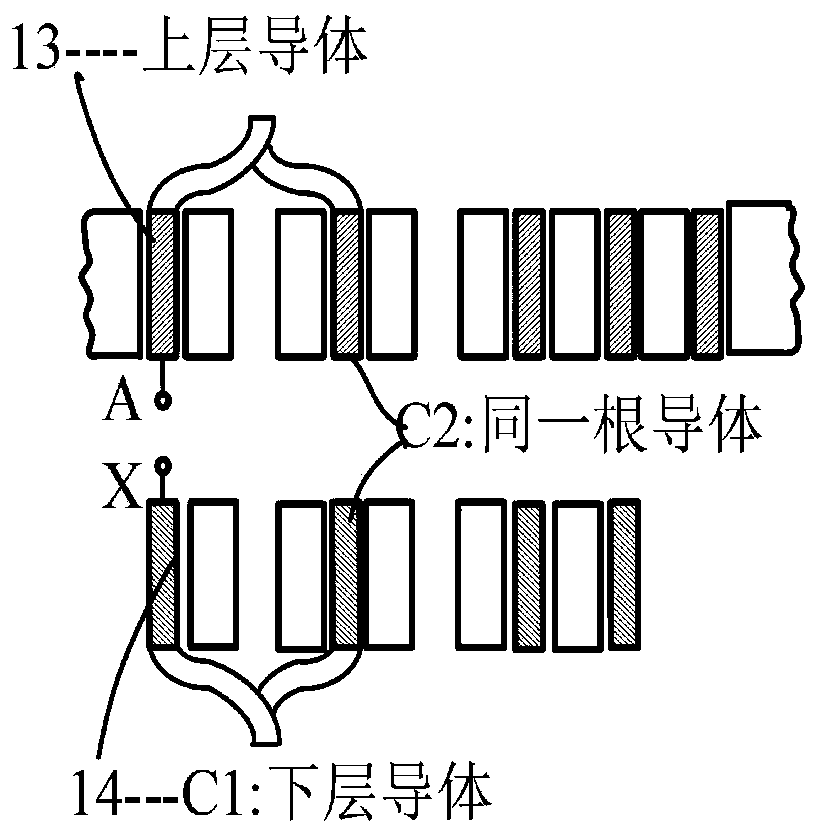

[0035] Such as figure 1 As shown, a winding includes: a plurality of coils; the coil is a 1.5-turn coil, and the coil includes a double-layer body module 12, a first conductor 11 and a connecting conductor module; the double-layer conductor module 12 and the The first conductor 11 is connected through the connecting conductor module; the double-layer conductor module 12 includes: a second conductor 13 and a third conductor 14; the connecting conductor module includes: a first connecting conductor 10 and a second connecting conductor 15; The second conductor 13 and the third conductor 14 are arranged side by side up and down, the input end of the second conductor 13 is the coil input end A, the output end of the third conductor 14 is the coil output end X, and the first The output end of the second conductor 13 is connected with the input end of the first conductor 11 through the first connecting conductor 10, and the output end of the first conductor 11 is connected with the i...

Embodiment 2

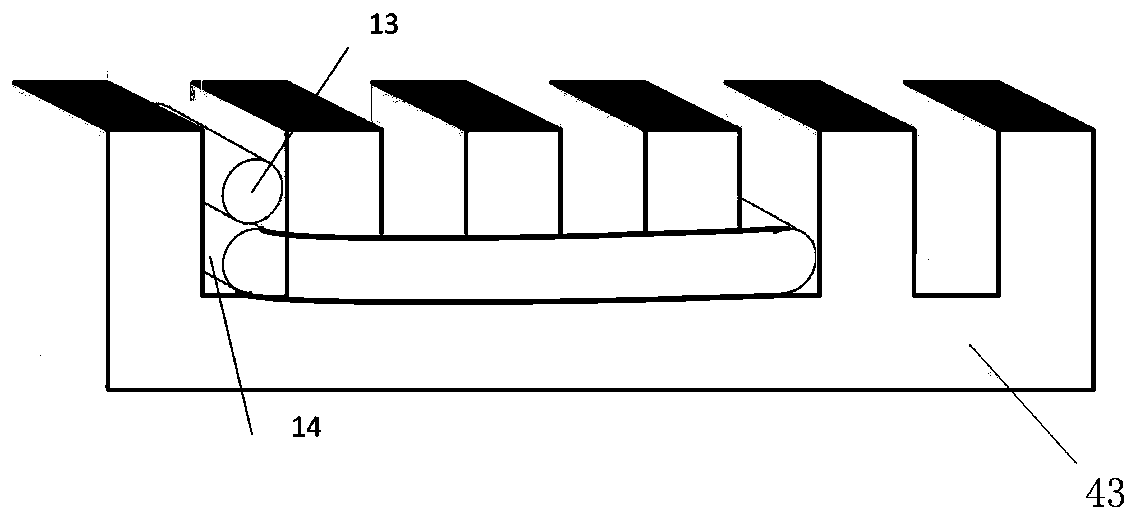

[0040] Such as Figure 2-Figure 3As shown, a stator includes: a stator core 43 and the winding described in Embodiment 1; m stator slots are uniformly arranged on the stator core 43; a double-layer conductor module of the nth coil of the winding (the first A plurality of stator slots are separated between the second conductor 13 and the third conductor 14) and the first conductor of the nth coil of the winding, and the double-layer conductor module of the nth coil of the winding is along the kth stator slot The slot edge of the stator core 43 is set in the kth stator slot of the stator core 43, and the first conductor of the nth coil of the winding is set in the stator core 43 along the slot edge of the k+bth stator slot. In the k+b stator slot; the double-layer conductor module of the n+1 coil of the winding is arranged in the k+b stator slot of the stator core 43 along the slot edge of the k+b stator slot , the first conductor of the n+1th coil of the winding is arranged in...

Embodiment 3

[0042] A motor whose magnetic flux is axially forming a main magnetic circuit, comprising: a rotor core 42, a magnetic steel 41 and the stator described in Embodiment 2, such as Figure 4-Figure 5 As shown, the magnetic steel 41 is arranged in the rotor slot of the rotor core 42 . The distance between the double-layer conductor module and the first conductor of the same coil of the stator is similar to the distance between the magnetic steel 41 in the adjacent rotor slot, which is equal to the pole pitch, shorter than the pole pitch, and longer than the pole pitch Three categories.

[0043] The arrangement equal to the pole distance is as Figure 6 As shown, the distances between the double-layer conductor modules and the first conductor 11 of all coils are equal. One rotor slot corresponds to one magnet steel 41 , the polarity of the magnet steel 41 is S pole or N pole, and the polarity of the magnet steel 41 in adjacent rotor slots is different. Figure 7 It is the view A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com