Device comprising nanowires and production method of device

A fabrication method and nanowire technology, applied in semiconductor/solid-state device manufacturing, nanotechnology, semiconductor devices, etc., can solve problems such as inability to fabricate nanowires, and achieve the effect of perfect lattice, good performance, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Methods of fabricating devices including nanowires include:

[0057] Provide a silicon substrate;

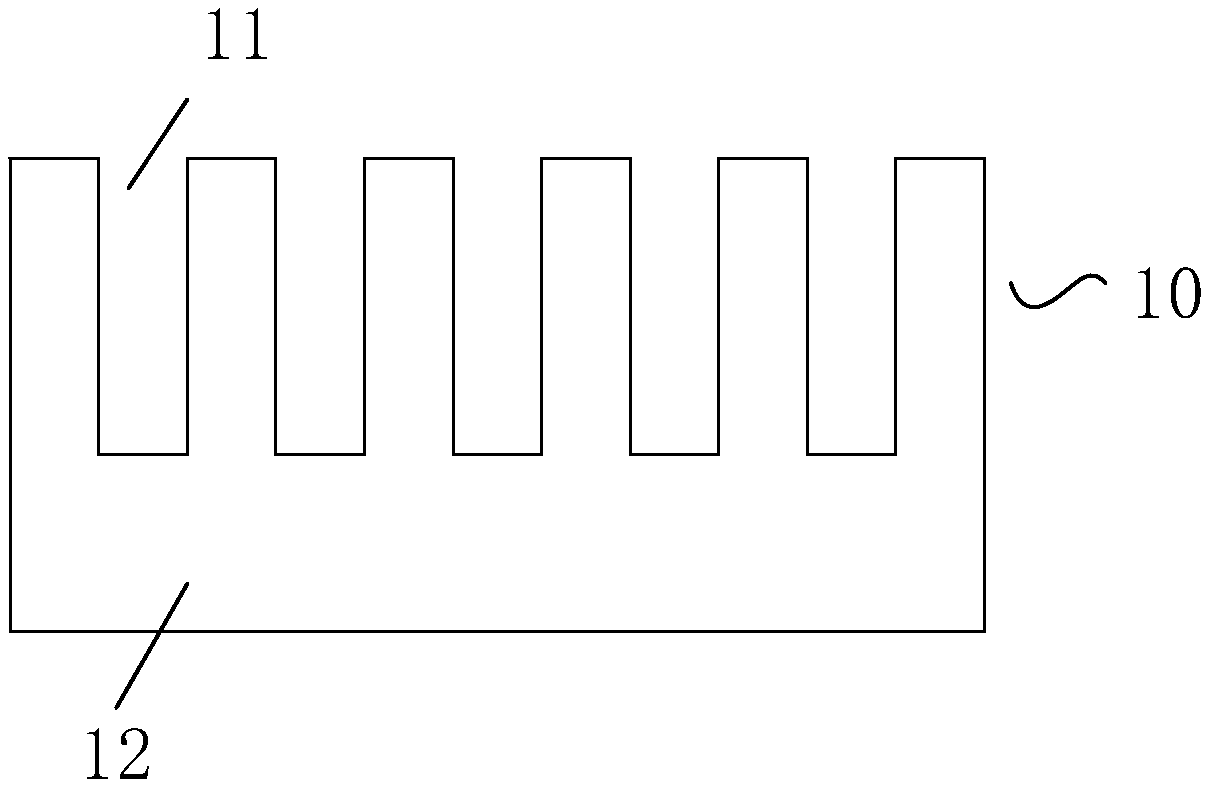

[0058] Using photolithography and plasma etching to dig a plurality of grooves with a width of 20nm (the distance between two adjacent grooves is 40nm) and a depth of 100nm on the silicon substrate, such as figure 1 shown;

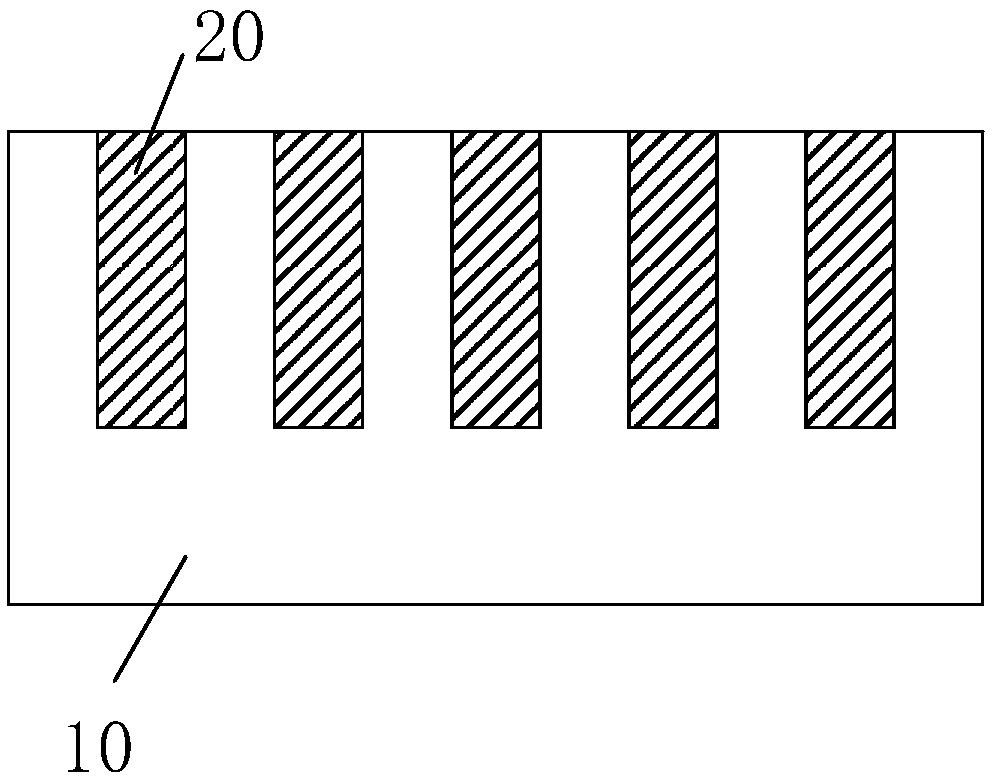

[0059] Using a thermal oxidation process, the substrate is thermally oxidized to form 1nm SiO 2 layer, and then use PECVD to deposit SiO in the groove 2 , and finally perform a CMP planarization process to form a similar figure 2 the structure shown;

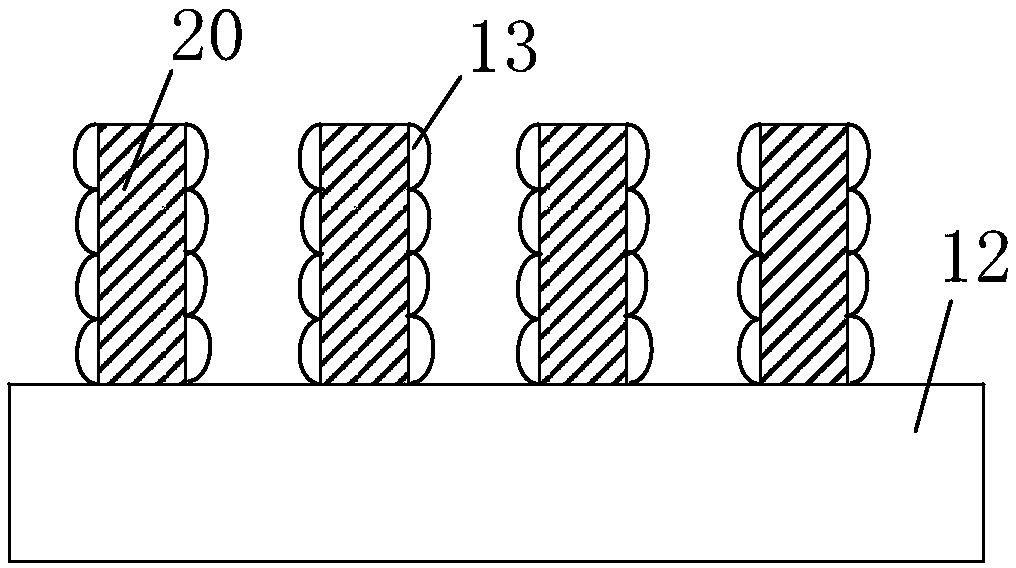

[0060] The second pre-nanowire is obtained by plasma alternate etching of anisotropic etching and isotropic etching, and the etching gas of anisotropic etching is SF 6 +O 2 , the etching gas for isotropic etching is SF 6 , the height of the second pre-nanowire is 3-6 nm;

[0061] Repeat the above process to obtain multiple stacked second pre-nanowires. For details, please refer to image 3 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com