Method for preparing semiconductor substrate with insulating buried layer and semiconductor substrate

An insulating buried layer, semiconductor technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components and other directions, can solve problems such as low device yield, achieve perfect lattice, no primary defects, low oxygen and metal content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Next, a method for preparing a semiconductor substrate with an insulating buried layer and specific implementations of the semiconductor substrate according to the present invention will be described in detail with reference to the accompanying drawings.

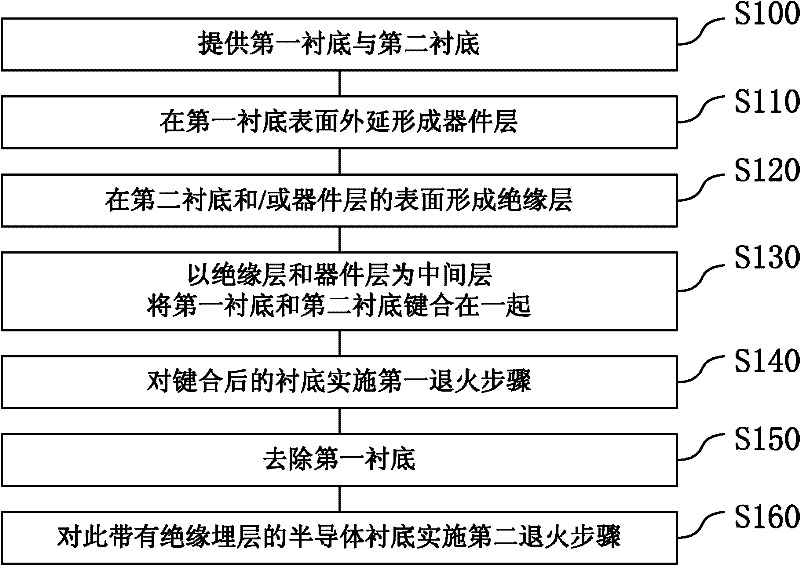

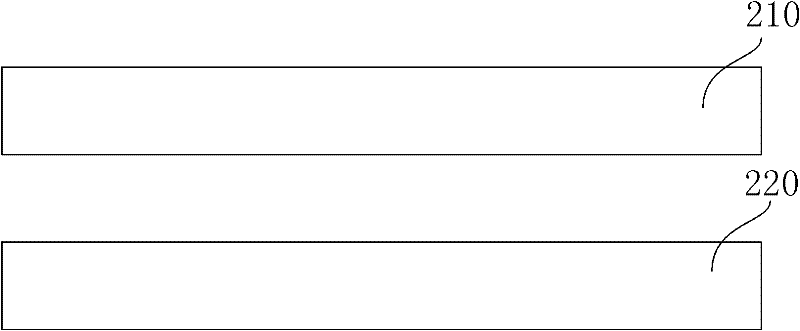

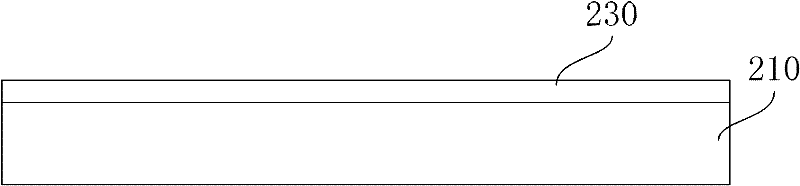

[0015] attached figure 1 Shown is a schematic diagram of the implementation steps of the method described in the specific embodiment of the present invention, including: step S100, providing a first substrate and a second substrate; step S110, epitaxially forming a device layer on the surface of the first substrate; step S120, in An insulating layer is formed on the surface of the second substrate and / or the device layer; Step S130, using the insulating layer and the device layer as an intermediate layer, bonding the first substrate and the second substrate together; Step S140, after bonding The substrate implements the first annealing step; Step S150, removes the first substrate to form a semiconductor substrate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com