Lead-acid capacitor battery and method for preparing lead-acid capacitor battery

A capacitor battery and lead-acid technology, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of poor charging and discharging efficiency, conductive discontinuous coating film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

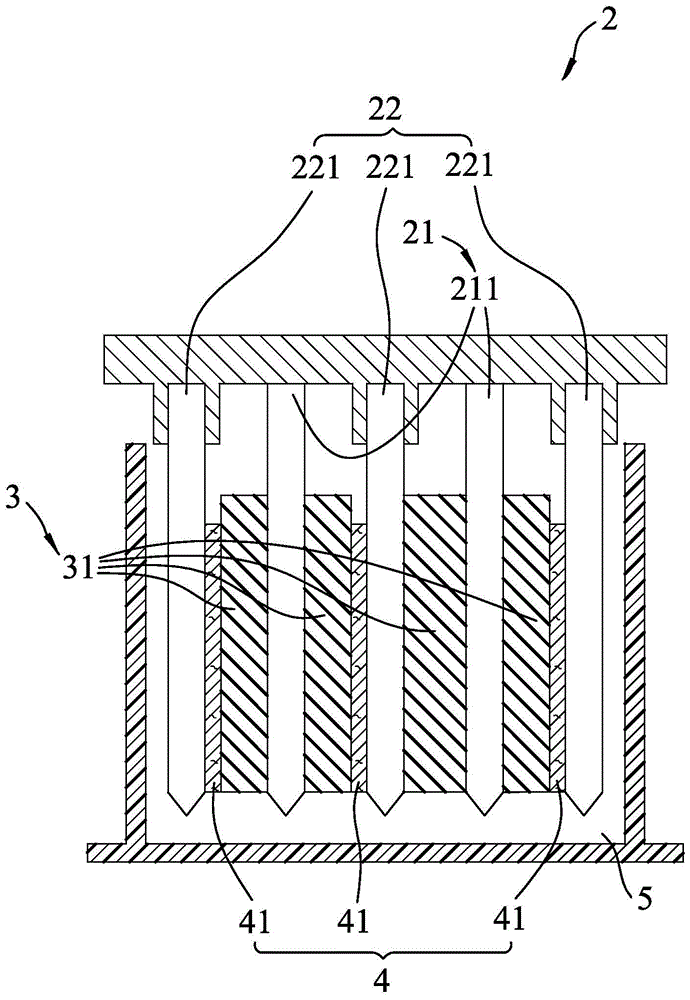

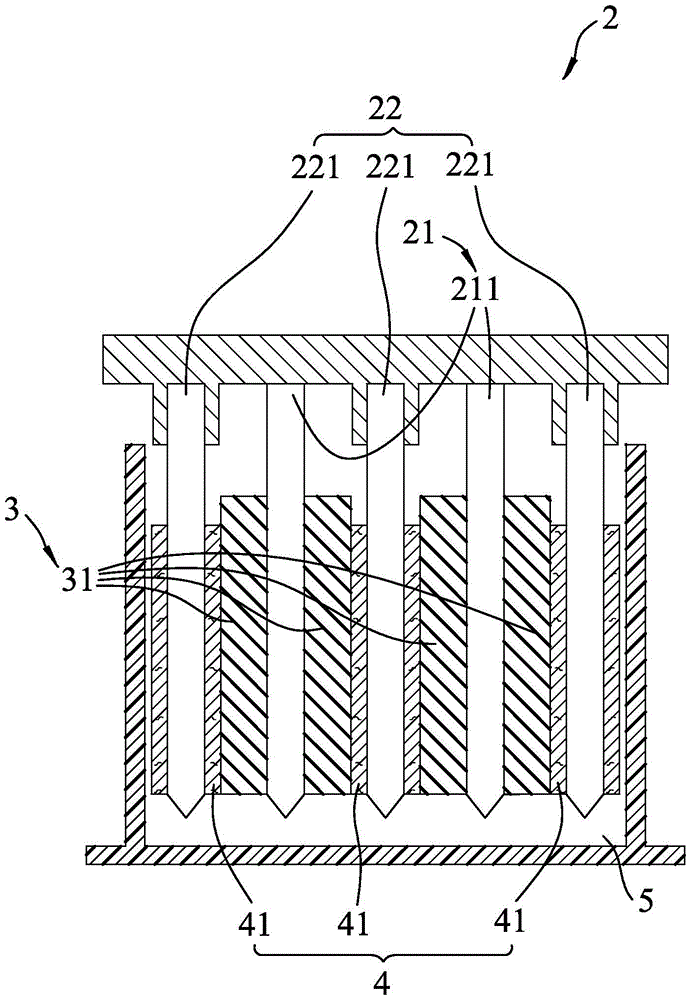

[0043] refer to figure 2, the first preferred embodiment of the lead-acid capacitor battery of the present invention comprises an electrode group 2, a separator unit 3, a continuous carbon fiber weaving unit 4, and an electrode group 2, the separator unit 3 and the continuous The electrolyte solution 5 that the carbon fiber weaving unit 4 contacts. There is no adhesive between the electrode group 2 and the continuous carbon fiber woven fabric unit 4 . The electrolytic solution 5 is sulfuric acid.

[0044] The electrode set 2 includes a positive electrode unit 21 and a negative electrode unit 22 spaced apart from the positive electrode unit 21 . The anode unit 21 includes two anodes 211 , and the anode unit 22 includes three anodes 221 . The separator unit 3 includes four separators 31 , which are respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com