Multilayer graphene flexible plate transfer printing method and graphene flexible plate assembly

A multi-layer graphene and graphene technology, applied in chemical instruments and methods, adhesive types, inorganic chemistry, etc., can solve problems such as inability to transfer graphene films, damaged electrical properties, and poor graphene films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

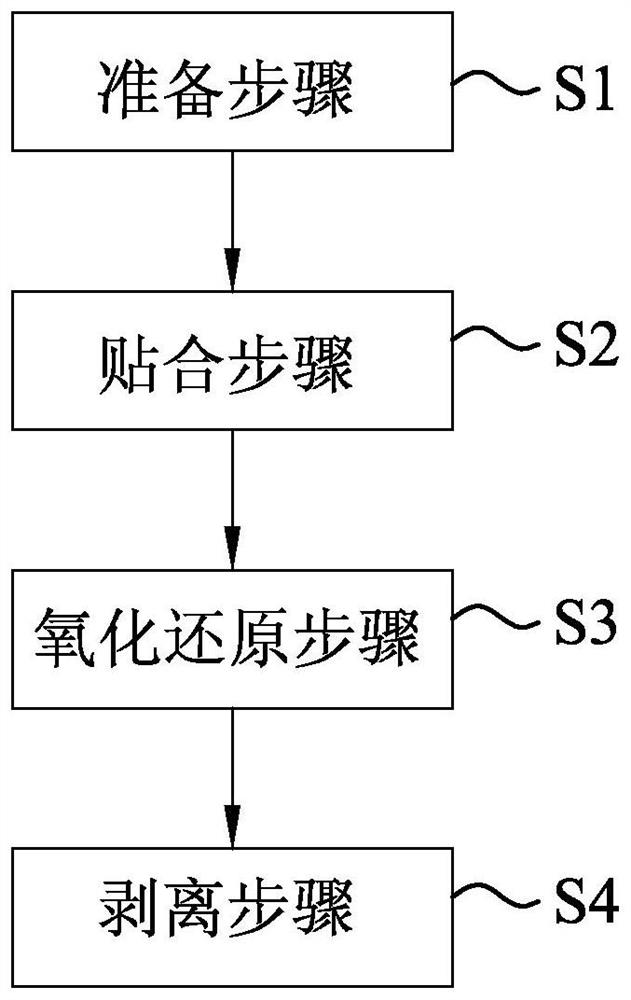

[0041] refer to Figures 1 to 4, an embodiment 1 of the present invention, comprising a preparation step S1, a bonding step S2, a redox step S3, and a peeling step S4.

[0042]

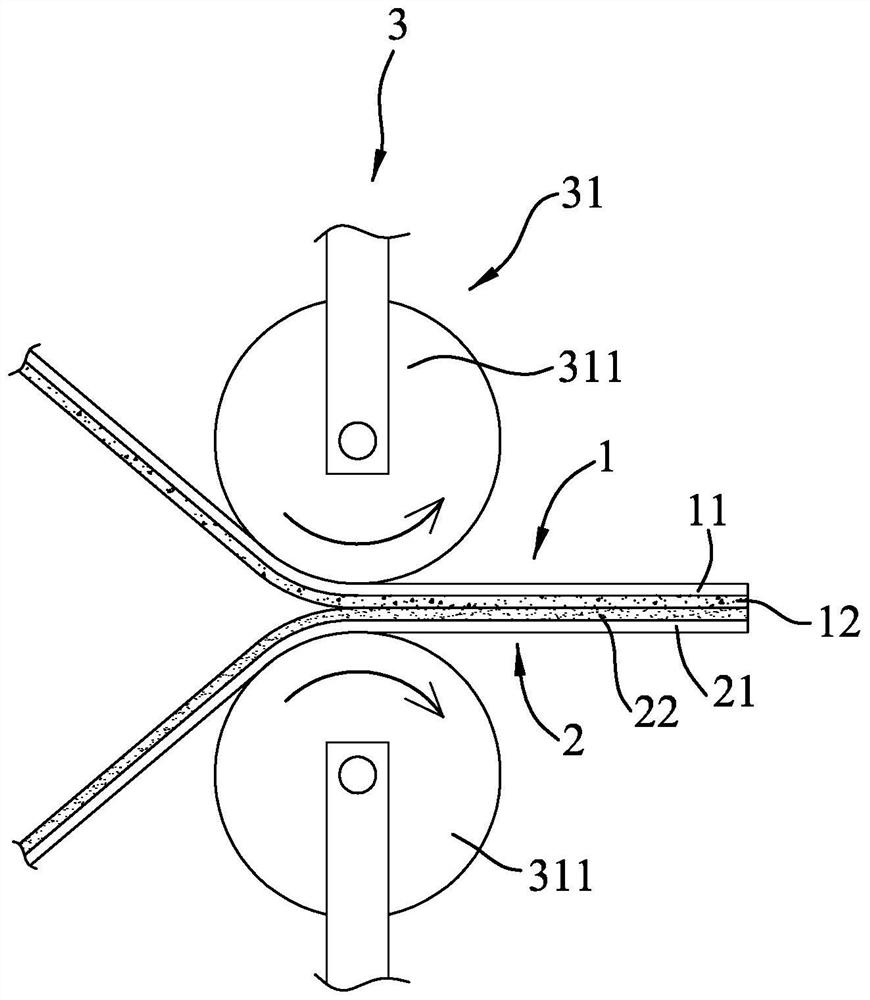

[0043] A transfer unit 1 , a flexible board unit 2 , and a roll-to-roll device 3 are provided.

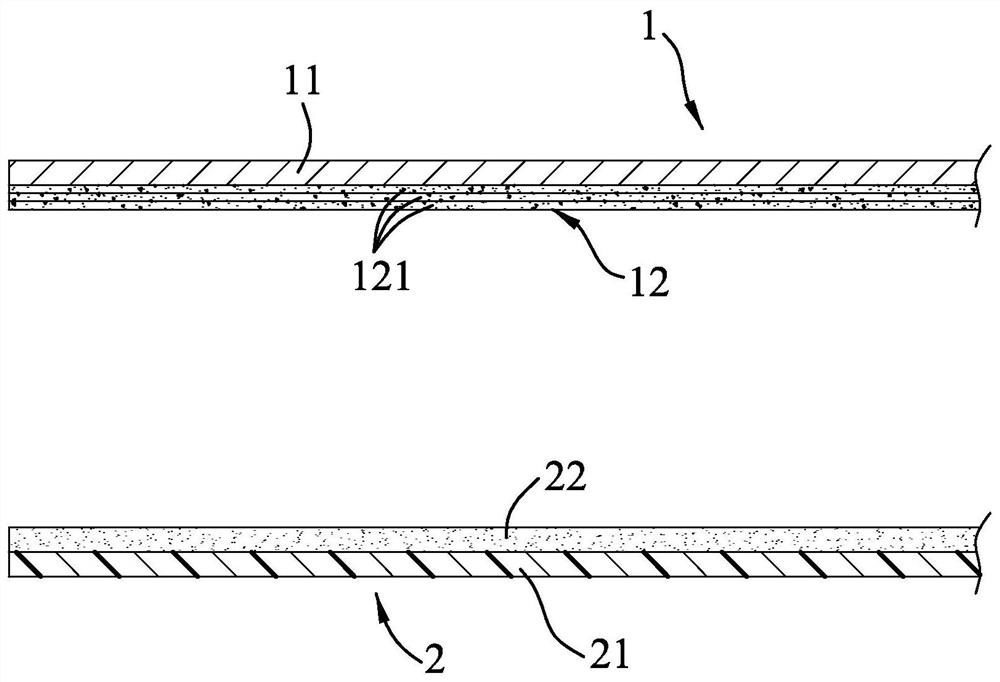

[0044] The transfer unit 1 includes a foil-shaped metal substrate 11 mainly composed of copper, and a graphene film 12 disposed on the metal substrate 11 . The graphene film 12 has several graphene layers 121 stacked on the metal substrate 11 . The flexible board unit 2 includes a flexible substrate 21 and an adhesive layer 22 disposed on the flexible substrate 21 . The adhesive force between the adhesive layer 22 and the metal substrate 11 is measured to be 0.25 kgf / cm. Next, the preparation method of the transfer unit 1 and the flexible board unit 2 , the structure of the roll-to-roll equipment 3 , and the test method of the adhesion between the adhesive layer 22 and the metal substrate 11 will be d...

Embodiment 2~4

[0072] Embodiments 2-4 are similar to this embodiment 1, the difference is:

Embodiment 2

[0073] Embodiment 2 is to get this polyimide colloid of 100g (containing polyimide 50g), and this epoxy resin of 20g is mixed into this bonding colloid. Therefore, if the total weight of the polyimide is 100 parts by weight, the epoxy resin is 40 parts by weight. The adhesive force between the adhesive layer 22 formed with the aforementioned adhesive colloid and the metal substrate 11 is 0.4 kgf / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com