Irregular object volume measurement method based on compressed sensing

A volume measurement and compressive sensing technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of limited application, inapplicability to dynamic scenes, large amount of calculation, etc., to reduce manual operations, promote industrial development, and improve the national economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

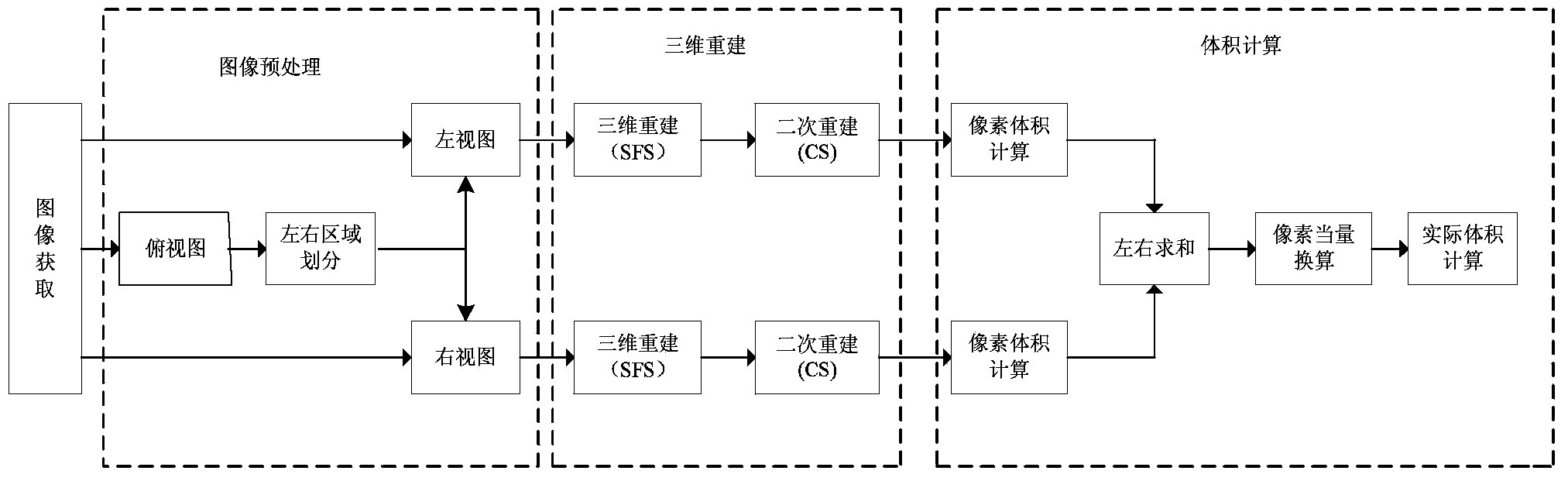

[0019] The present invention takes stones as the measured object, and the processing flow is as attached figure 1 As shown, the specific implementation steps are as follows:

[0020] Step1. Install three cameras located in the left, right, and upper directions of the irregular object to be measured to form a volume measurement system. First, calibrate the volume measurement system, that is, use the system to measure an object whose geometric parameter L is known. Get the number of pixels M representing its parameters, and then use the formula ε=L / M to calculate the pixel equivalent ε to get the actual size represented by the unit pixel.

[0021] Step2. Obtain the top view and left and right side views of the object to be tested through the CCD camera.

[0022] Step3. Use the Otsu method threshold segmentation to binarize the top view.

[0023] Step4. Obtain the position of the upper and lower vertices of the top view, take the horizontal symmetrical centerline of the two, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com