Tungstic acid thin film air-sensitive sensor surface modifying method

A gas sensor, tungsten trioxide technology, applied in the field of gas sensors, can solve the problems of high working temperature, poor selectivity, long recovery time, etc., achieve the effect of uniform thickness, improved gas sensing performance, and increased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

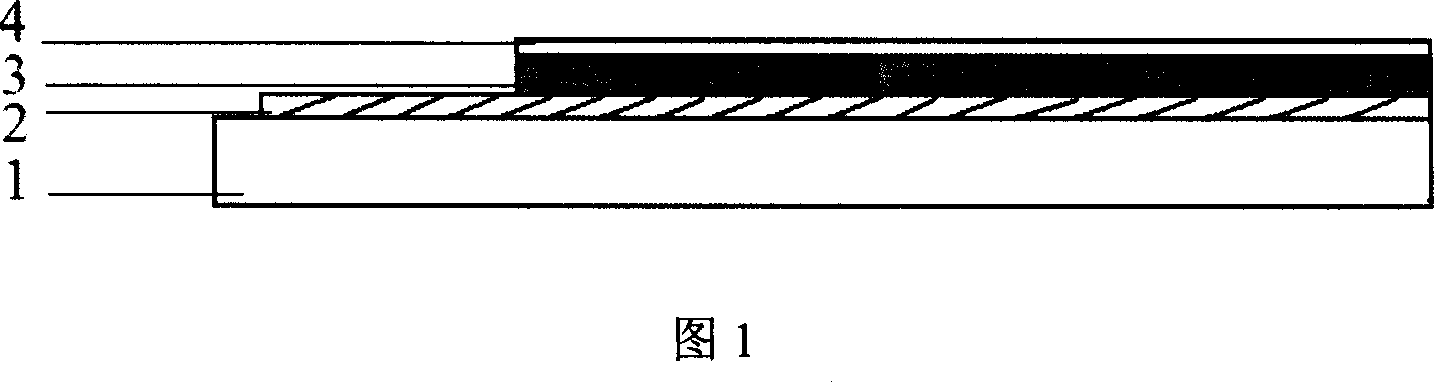

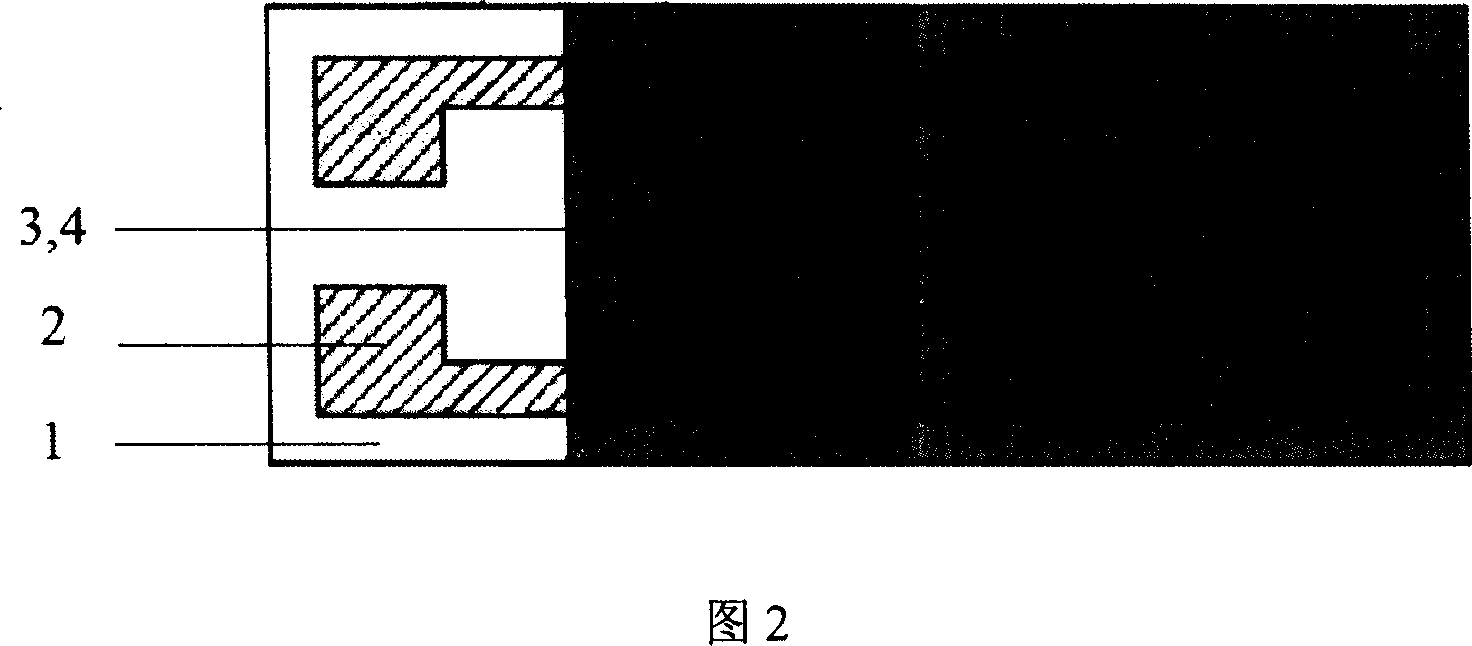

[0020] 1) Using Al with a thickness of 350 μm, a length of 2.5 cm, and a width of 1.0 cm 2 o 3 The ceramic substrate was ultrasonically cleaned with acetone for 10 minutes, rinsed with deionized water, then ultrasonically cleaned with absolute ethanol for 10 minutes, rinsed with deionized water, and dried at 50°C for later use; 2) Al 2 o 3 An iron finger mask with a thickness of 100 μm is attached to the ceramic substrate. Masked Al 2 o 3 The substrate is placed in the vacuum chamber of the DPS-III type ultra-high vacuum facing target magnetron sputtering equipment. The metal platinum with a mass purity of 99.95% is used as the target material, and argon gas with a mass purity of 99.999% is used as the working gas. The specific steps of controlled sputtering are: pumping the vacuum to 2.5×10 -4 Pa, the argon gas flow rate is 25ml / min, the sputtering working pressure is 2.0Pa, the sputtering power is 80W, the sputtering time is 7 minutes, and the substrate temperature is 2...

Embodiment 2

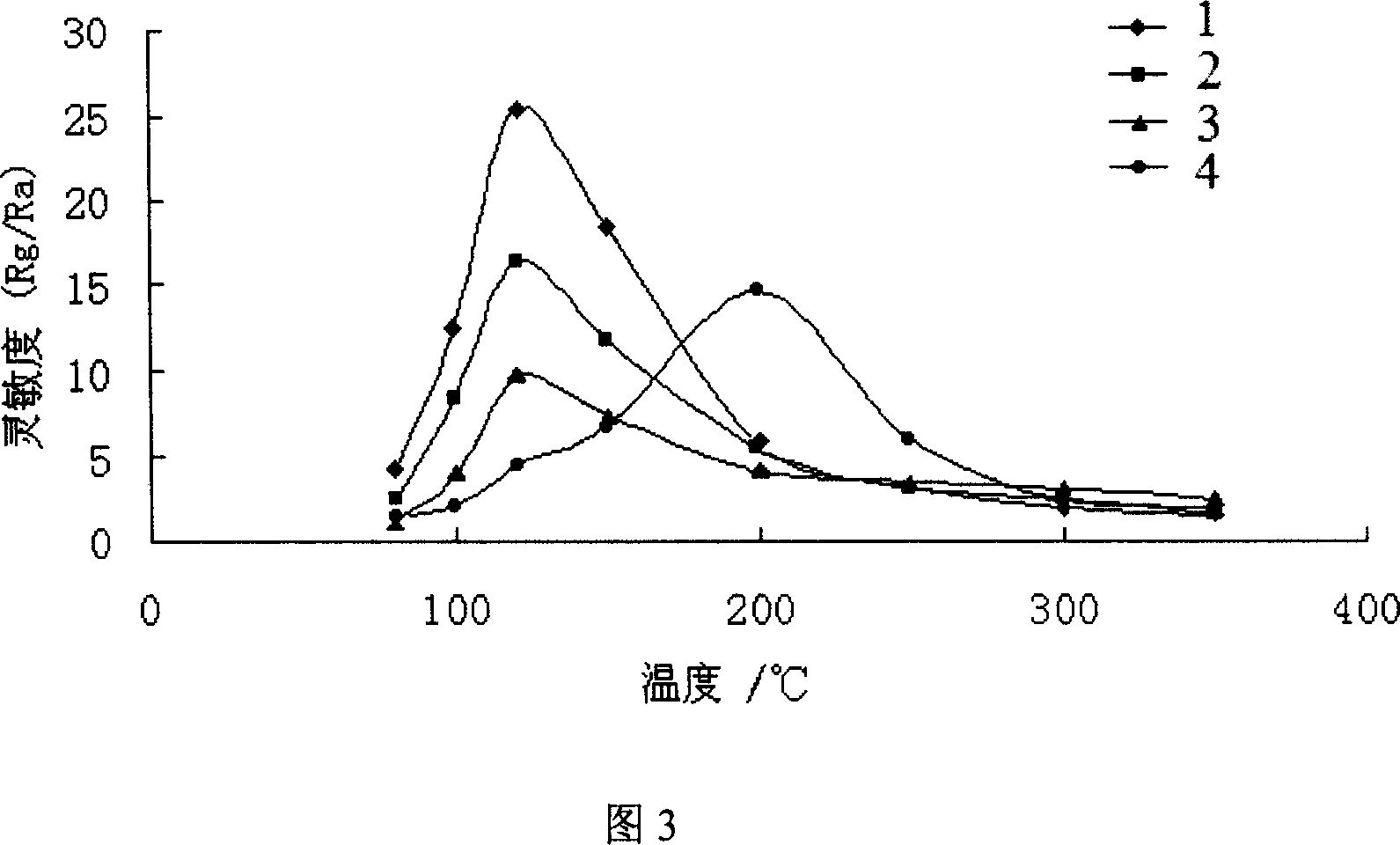

[0022] This embodiment is similar to Embodiment 1, except that the sputtering time of metal titanium in step 4) is 20 minutes, and a titanium oxide layer with a thickness of 0.06 μm is obtained on the surface of the tungsten trioxide layer. Sensitivity test was carried out on the prepared tungsten trioxide thin film gas sensor, and the relationship curve between sensitivity and working temperature is shown in curve 1 in Fig. 3 . It can be seen from Figure 3 that not only the operating temperature of the tungsten trioxide thin film gas sensor is greatly reduced, but also the sensitivity is greatly improved.

Embodiment 3

[0024] The present embodiment is similar to Embodiment 1, except that the working pressure of titanium sputtering in step 4) is 0.5Pa, the sputtering time is 15min, and the flow rate of argon gas is 22ml / min. Titanium oxide layer with a thickness of 0.04 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com