Device and method for controlling NOx of circulating fluidized bed by coupling air staging and fuel staging

A technology of circulating fluidized bed and air classification, which is applied in the field of circulating fluidized bed, can solve the problems of not adopting fuel classification combustion technology, the boiler cannot produce natural gas, and the price of natural gas is high, so as to reduce emissions, ensure combustion efficiency and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

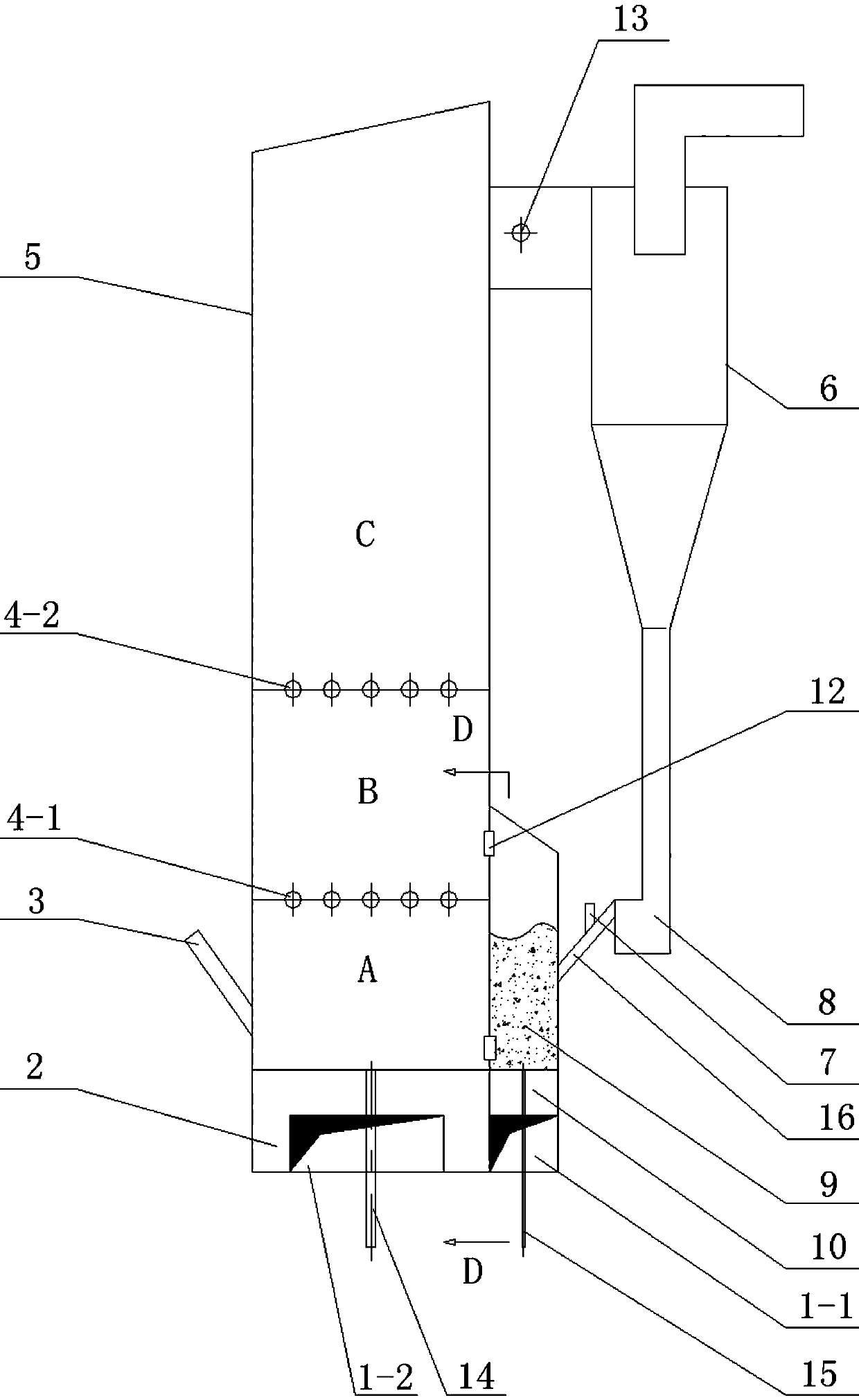

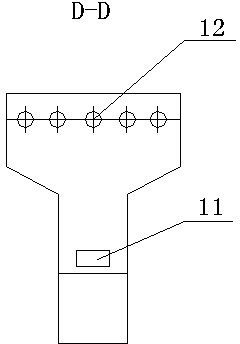

[0021] Specific implementation mode one: as figure 1 and figure 2 As shown, air staging and fuel staging are coupled to control circulating fluidized bed NO x The device includes a furnace body 5, a cyclone separator 6, a return valve 8, and a connecting pipe 16; the furnace body 5 is a circulating fluidized bed, and it is characterized in that: the air classification and the fuel classification are coupled to control the circulating flow BNO x The device also includes gasification chamber 9 and gasification chamber air chamber 10;

[0022] The lower part of the furnace body 5 is the main bed air chamber 2, the bottom of the furnace body 5 is provided with the main bed primary tuyere 1-2, and the lower part of the front wall of the furnace body 5 is located above the main bed air chamber 2 to arrange a primary fuel feeding port 3. The lower secondary tuyere 4-1 is arranged on the furnace body 5 above the primary fuel feeding port 3, and the upper secondary tuyere 4-2 is ar...

specific Embodiment approach 2

[0024] Specific implementation mode two: as figure 1 As shown, the coupling of air staging and fuel staging described in the first specific embodiment controls the circulating fluidized bed NO x device, the air staging and fuel staging are coupled to control circulating fluidized bed NO x The device also includes an SNCR denitration device 13; the SNCR denitration device 13 is installed at the outlet of the burnout zone C of the furnace body 5.

[0025] In this embodiment, since the SNCR denitrification device 13 is installed at the outlet of the burnout zone C of the body of furnace 5, urea is used as a reducing agent, and the urea aqueous solution is atomized from the separator 6 inlet and then sprayed into the flue. 6 Intensely mixed with flue gas to further reduce NO x emissions, can make the final NO x Emissions below 50mg / m 3 .

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 and figure 2 As shown, using the device described in the first or second embodiment to realize the coupling of air staging and fuel staging to control circulating fluidized bed NO x The method for discharging, described method comprises the steps:

[0027]Step 1: Add secondary fuel into the secondary fuel feeding port 7, the secondary fuel is fine coal particles with a particle size less than 1mm, and the high-temperature circulating material separated by the secondary fuel and the cyclone separator 6 Fully mixed in the chemical chamber 9; the temperature of the high-temperature circulating material is 850~950°C;

[0028] Step 2: Introduce air or steam or air plus steam from the bottom of the gasification chamber 9 as the fluidization medium of the gasification chamber 9, and fluidize the mixture of the high-temperature circulating material and the secondary fuel entering the gasification chamber 9 well, Gas is generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com