Gas turbine engine mild combustor and control method thereof

A combustion chamber and gentle technology, applied in combustion methods, combustion chambers, continuous combustion chambers, etc., can solve the problem of immature coal-to-synthesis gas lean premixing technology, limited nitrogen oxide emission potential, and difficulty in reducing nitrogen oxides, etc. problems, to achieve ultra-low nitrogen oxide emissions, increase the residence time of flue gas, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

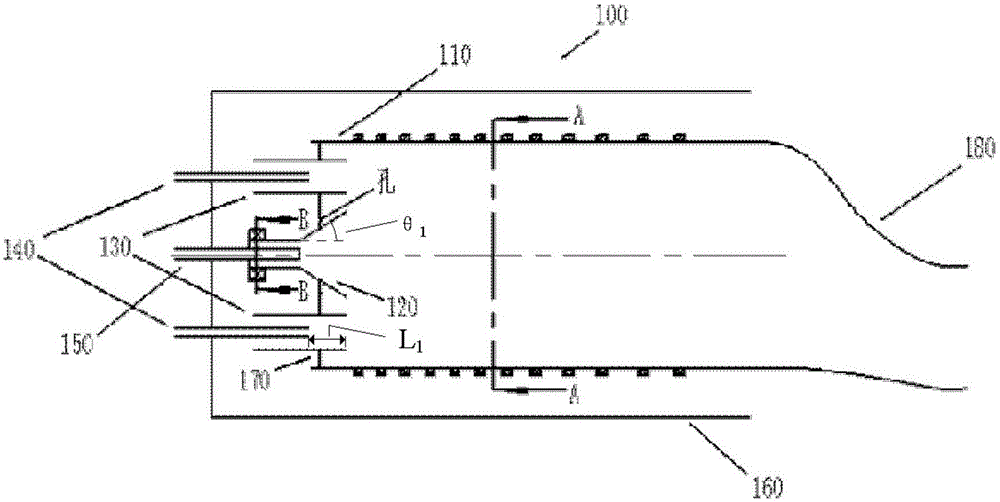

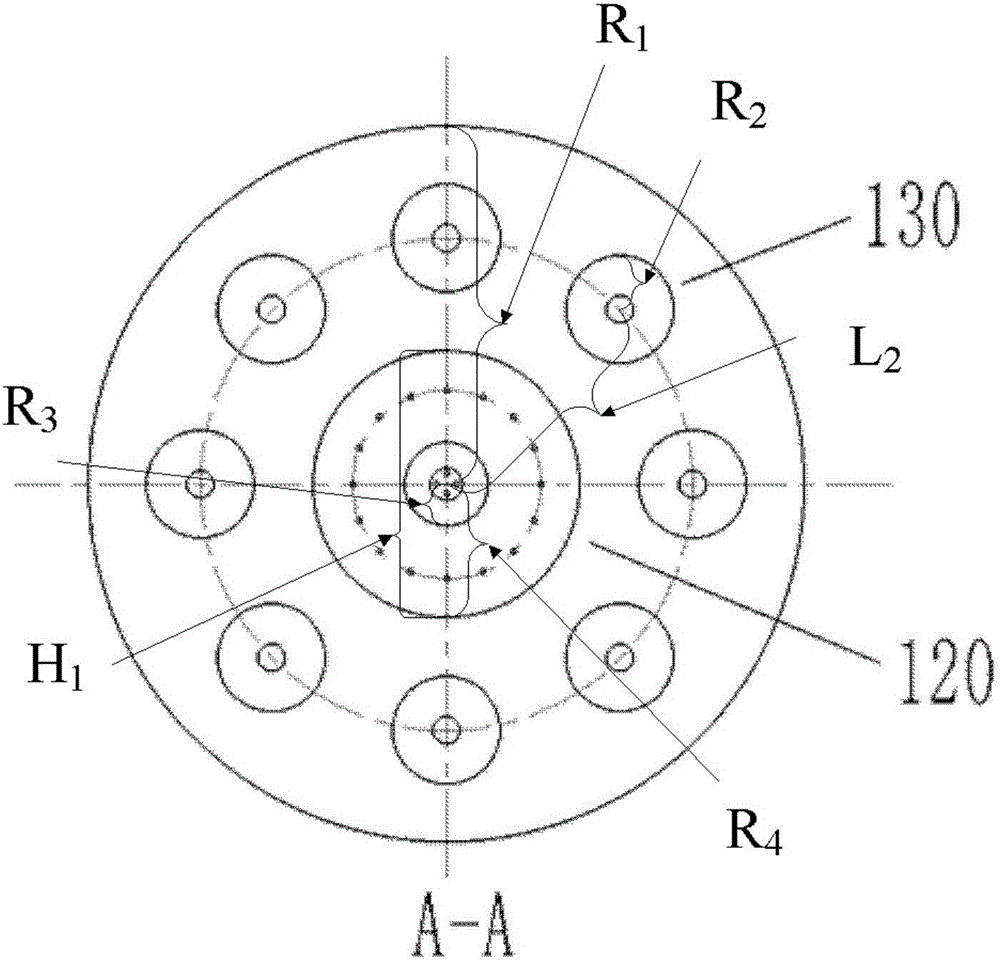

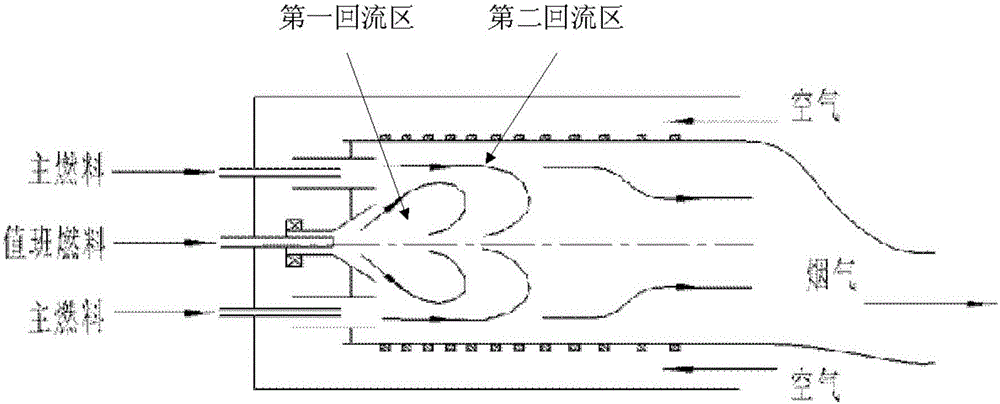

[0042] In the present invention, jet nozzles and on-duty swirl nozzles are arranged in the combustion chamber, and the joint action of the jet nozzles and on-duty swirl nozzles is used to form a high-efficiency low-pressure drop backflow inside the combustion chamber, and the mixed gas jet entrains high-temperature flue gas to quickly form high-temperature and low-oxygen The mixture reduces the mixing time and improves the mixing efficiency, which can directly realize soft combustion and effectively reduce the peak flame temperature during the combustion process, thereby achieving ultra-low nitrogen oxide emissions. On the premise of ensuring the combustion efficiency and performance of the combustion chamber, the invention can realize ultra-low nitrogen oxide emission in a wide load range, the combustion chamber has a compact structure, and is suitable for natural gas, coal-based synthesis gas and other medium and low calorific value Combustion of syngas.

[0043] In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com