Method for achieving water-injecting high-pressure combustion through pipeline of fuel nozzle

A combustion method and oil nozzle technology, which are used in burners, earth-moving drilling, and fluid production, etc., can solve the problems of shortened service life (sometimes less than one working day of gas injection, prone to bursting, denudation, difficult practical application, etc.) Achieve the effect of prolonging the continuous working cycle, improving work stability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

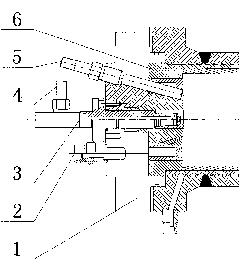

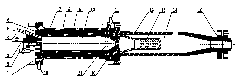

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The purpose of the present invention is to provide a new method for the oil thermal recovery gas injection high-pressure mixed gas generating device, which can create a reliable, easy-to-operate, long service life (main components can be continuous) for the recovery of oil, especially heavy oil. Work 8000 hours), energy-saving and efficient alternative new technology.

[0023] The device uses diesel oil, crude oil, natural gas or liquefied petroleum gas and compressed air to produce high-temperature and high-pressure flue gas mixed with water, thereby producing temperature and humidity that can be adjusted according to requirements, mainly composed of N2, CO2, water vapor (H2O) of the gas mixture. The mixed gas generating device is mainly used in the thermal exploitation of petroleum. The mixed gas generated by the mixed gas generating device can be directly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com