Top-mounted turbulent burner with low NOx emission for water-coal-slurry steam-injection boiler

A technology for steam injection boilers and coal-water slurry, which is applied to burners, lighting and heating equipment, etc., can solve the problems of ash and slag pollution and high NOx emissions, and achieve the effects of high cost, reduced NOx emissions, and low NOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

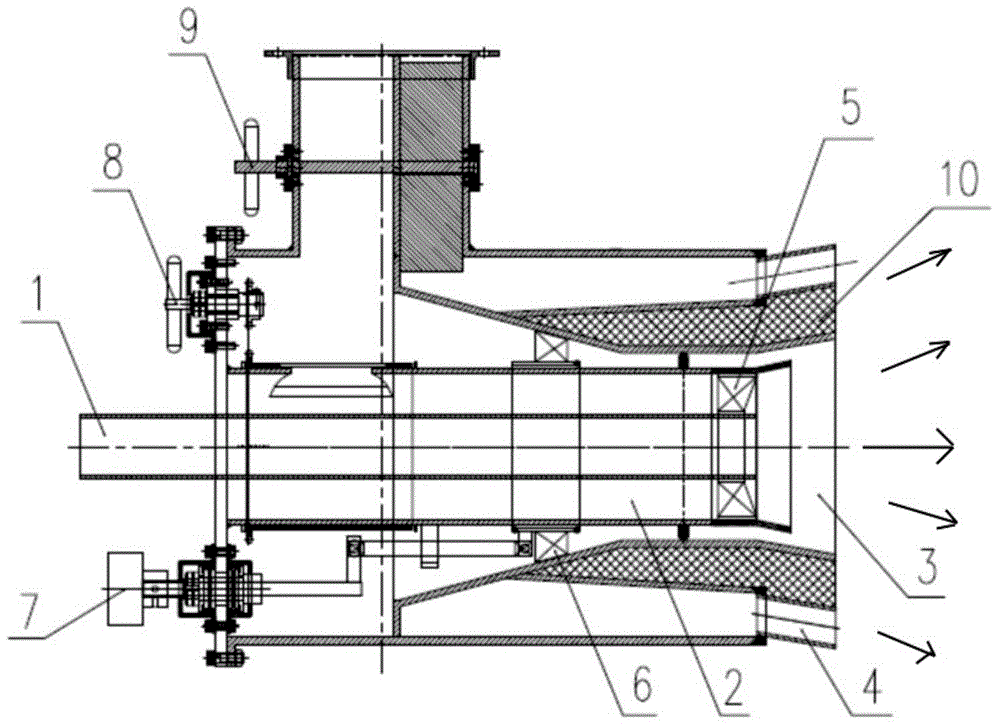

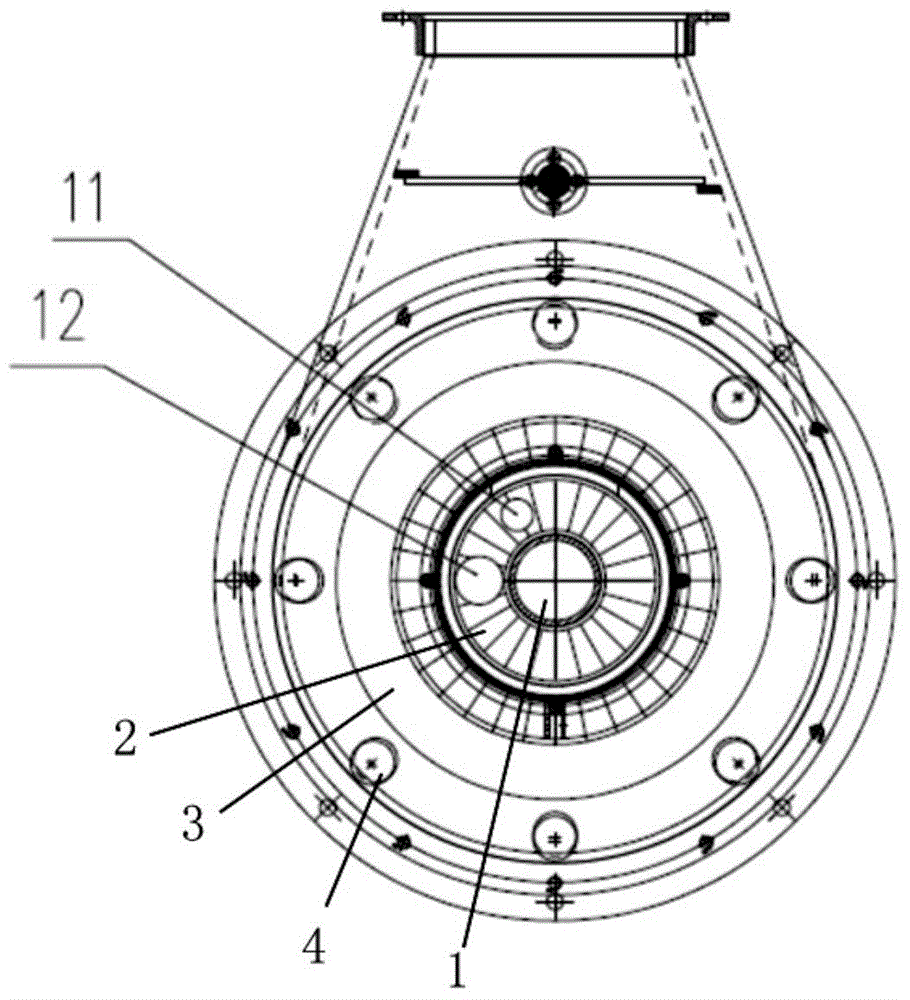

[0015] Attached below figure 1 And attached figure 2 , to illustrate the specific implementation of the present invention.

[0016] The coal water slurry low NOx burner is arranged on the top of the steam injection boiler, figure 1 Arrows are wind direction. From the inside to the outside, there are coal water slurry gun casing 1, primary air duct 2, and inner secondary air duct 3, which are arranged concentrically. The center is the coal water slurry channel, the periphery is the swirl primary air channel, and the outer layer is the The inner secondary air channel of the swirling flow has 8 outer secondary air pipes 4 arranged in a ring at the outermost layer, and all the nozzles face downward. Among them: the primary air cyclone 5 is installed at the outlet of the primary air duct, and the swirl strength is fixed, and the air volume can be adjusted through the primary air door adjustment device 8; the inner secondary air cyclone 6 is installed in the middle of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com