Swinging arm type transmission line polling robot

A technology for patrolling robots and power transmission lines, applied in the field of robotics, can solve problems such as high risk, difficulty in ensuring accuracy, and low inspection efficiency, and achieve strong obstacle-crossing capabilities, extended operating range, and low-accuracy solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

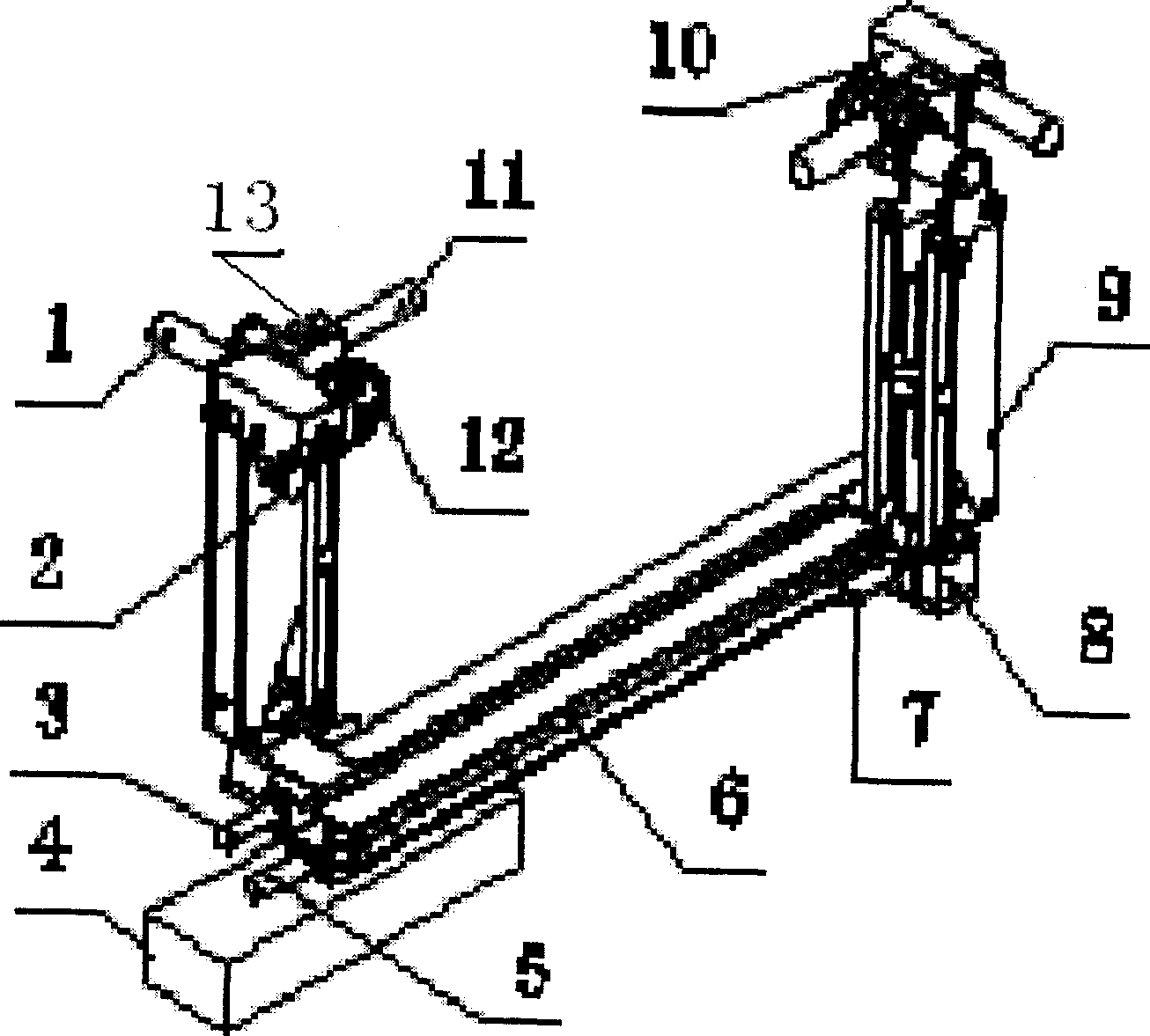

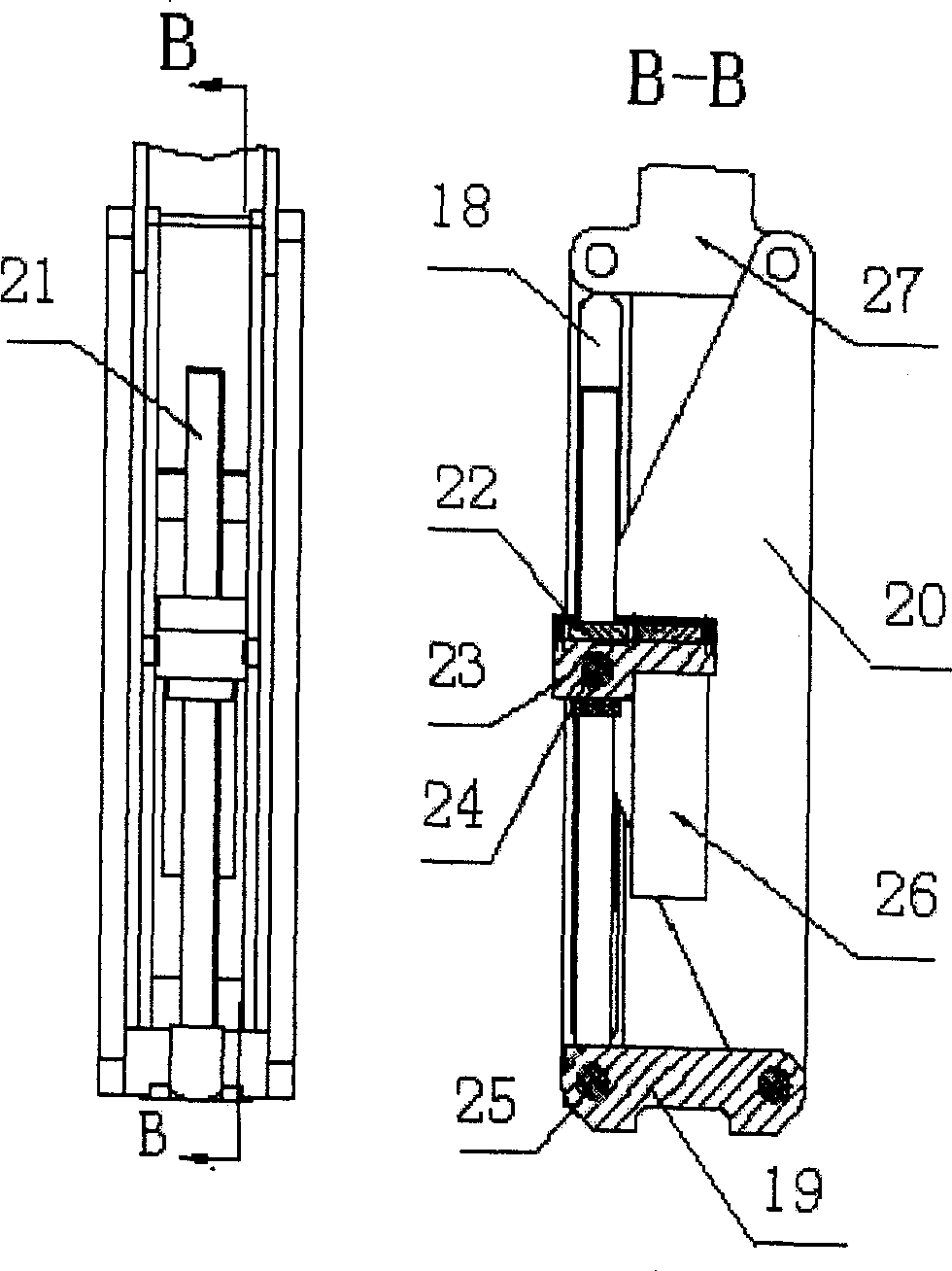

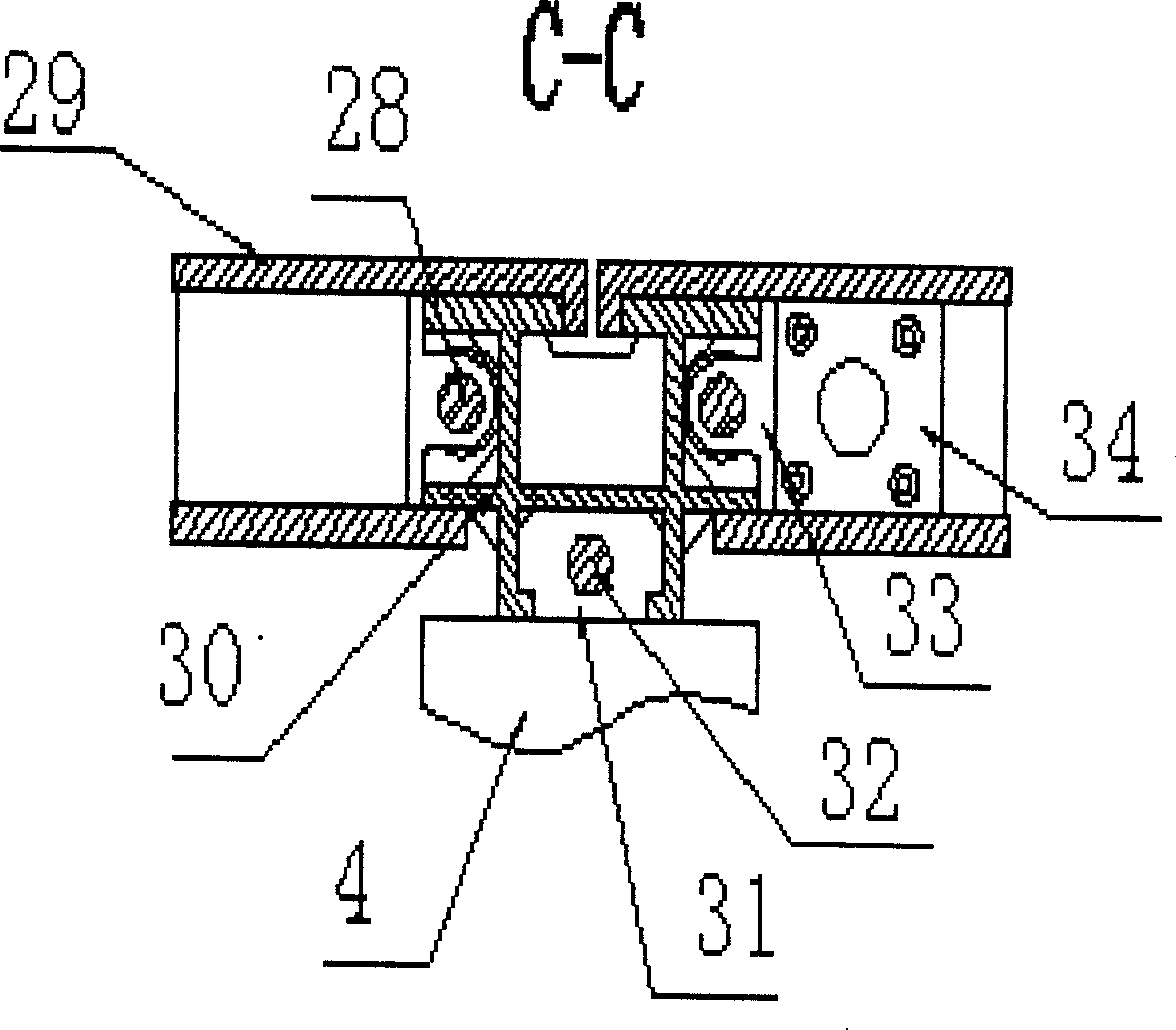

[0011] Reference attached Figure 1-6 , illustrating the implementation of the structure of the swing arm type transmission line automatic inspection robot structure is as follows:

[0012] The transmission line inspection robot of the present invention includes a pair of arms 9, and the upper end of the arms 9 is equipped with a clamping device 10, which includes a roller 12 that can be hung on the transmission line and a multipurpose gripper 2 that can grasp the angle steel and the transmission line. The lower end of the arm is connected to the sliding table 8 that can slide along the guide rail, and the arm can also rotate around the connecting axis in the vertical plane. Each small arm has 3 degrees of freedom. The pitch joint for axis rotation.

[0013] In the clamping device 10 , the jaw driving motor 1 drives the screw rod-rack-gear to rotate, so as to realize the loosening and clamping of the jaws. The rollers 12 are directly driven by the roller drive motor 11 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com