Radioactive waste liquid storage tank bottom mud withdrawing method and system

A technology for radioactive waste liquid and storage tanks, which is applied in radioactive purification, nuclear engineering and other directions, can solve the problems of large differences in the characteristics of the sediment in the structure form, a large amount of residual mud at the bottom of the tank, and difficulty in recovering the sediment, and achieve the stirring effect. Better, avoid close contact, ensure the effect of traffic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

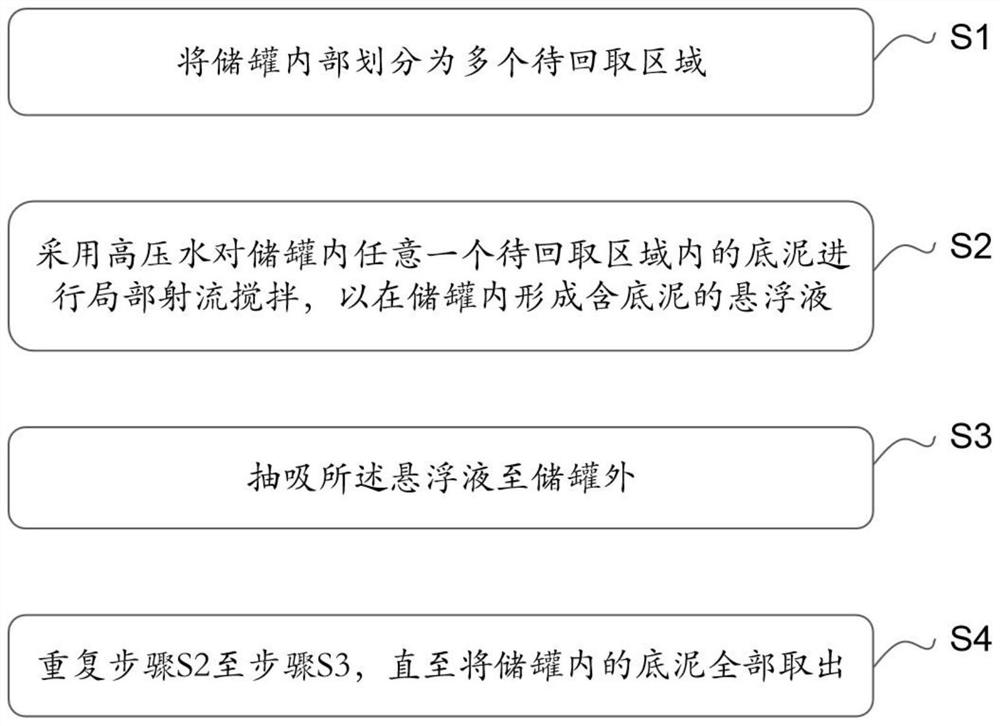

[0059] Such asfigure 1 As shown, this embodiment discloses a method for retrieving bottom sludge of a radioactive waste liquid storage tank, including:

[0060] S1, divide the interior of the storage tank into multiple areas to be retrieved.

[0061] Specifically, the bottom of the storage tank can be divided into multiple areas to be retrieved according to its area. The area to be retrieved is the area where residual mud (ie bottom mud) needs to be retrieved. The size of each area to be retrieved can be determined according to The working range of the device used to perform the retrieval operation is determined.

[0062] S2, using high-pressure water to locally jet-stir the sediment in any area to be retrieved in the storage tank, so as to form a suspension containing sediment in the storage tank.

[0063] A stirring device is used to carry out local jet agitation of the sediment. The agitating device includes a high-pressure water unit and a nozzle. The high-pressure water ...

Embodiment 2

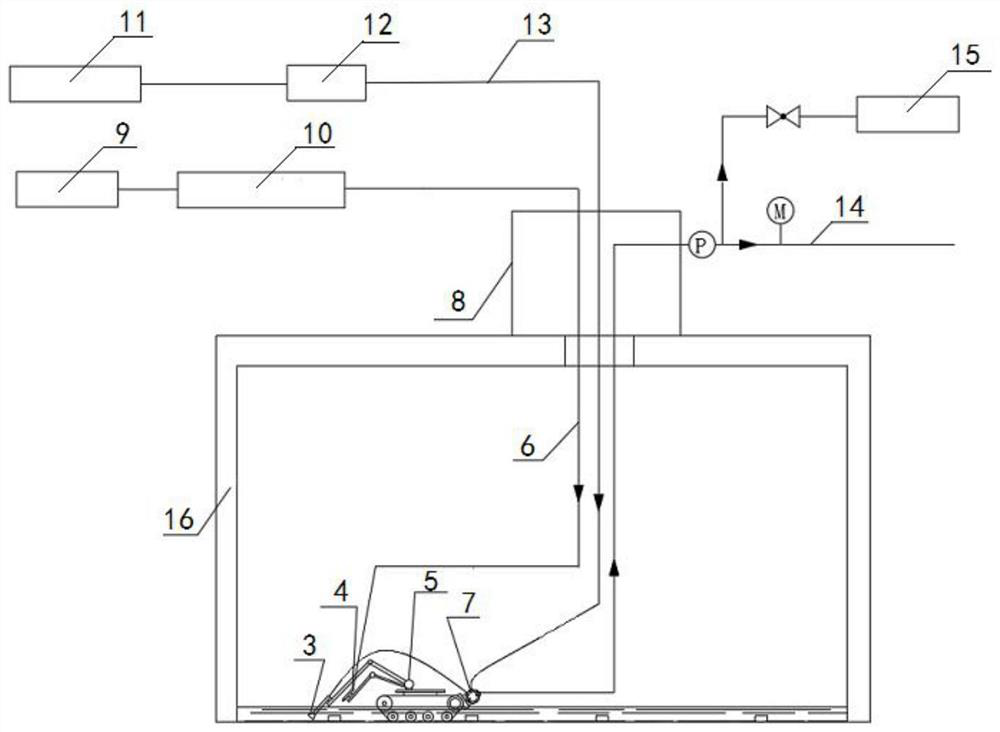

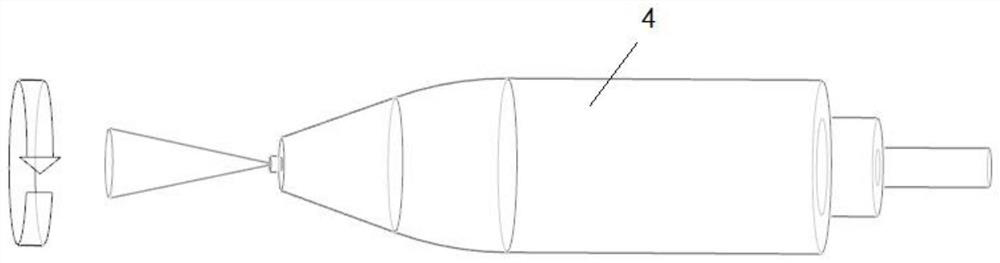

[0073] Such as figure 2 As shown, this embodiment discloses a system for retrieving the bottom mud of a radioactive waste liquid storage tank, including a stirring device and a suction device, wherein: the stirring device uses high-pressure water hydraulic jets for stirring, and includes a high-pressure water unit and a nozzle 4. The water unit is connected with the nozzle 4, and is used to provide high-pressure water to the nozzle, so that the high-pressure water jet sprayed by the nozzle 4 can locally jet-stir the sediment in the storage tank 16, and form a suspension containing sediment (i.e. solid-liquid Mixture 18); suction device for suctioning the suspension.

[0074] Specifically, the high-pressure water unit includes high-pressure water generating equipment 12 and production water supply equipment 9 for supplying water to the high-pressure water generating equipment. The high-pressure water generating equipment 12 can adopt a high-pressure water pump, such as a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com