Robot three-dimensional scanning device and robot three-dimensional scanning method

A technology of three-dimensional scanning and robotics, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of scanning blind spots, low scanning accuracy, long scanning time, etc., to achieve increased working range, high scanning accuracy, and scanning speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

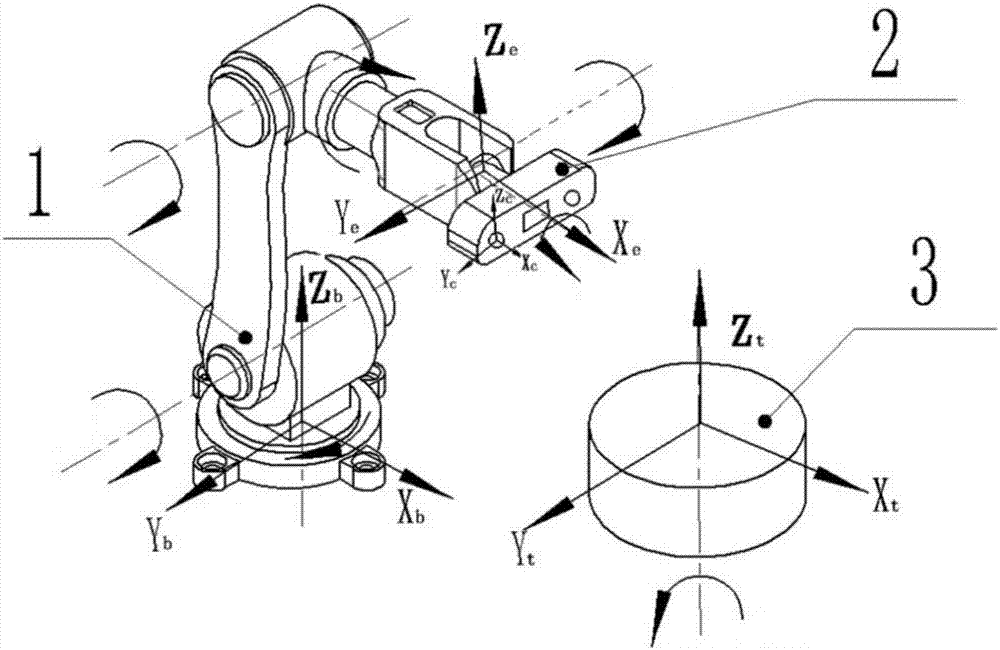

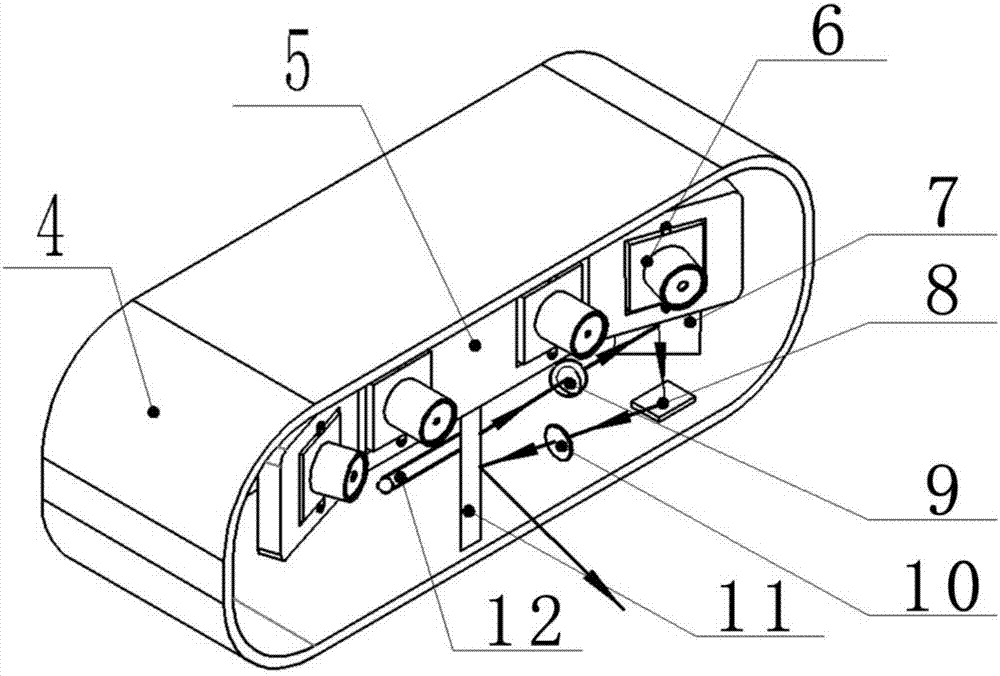

[0030] A robot three-dimensional scanning device ( figure 1 shown) is composed of six-axis robotic arm (1), MEMS scanning galvanometer laser three-dimensional measuring head (2), and turntable (3); among them, MEMS scanning galvanometer laser three-dimensional measuring head ( figure 2 Shown) consists of MEMS probe housing (4), camera support plate (5), CCD camera (6), mirror surface (7), MEMS vibrating mirror (8), collimating lens (9), aspheric lens (10) , a reflector (11) and a laser (12), and the scanning measuring head is placed at the end of the six-axis mechanical arm.

[0031] The MEMS scanning galvanometer laser three-dimensional measuring head ( figure 2shown), the arrow represents the laser light path, and the part that the light path passes is the laser MEMS projection device, and its working method is as follows: the laser beam emitted by the laser is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com