Self-repairing type grid drive circuit

一种栅极驱动电路、自修复的技术,应用在液晶领域,能够解决薄膜晶体管失效、影响Gate波形延迟、GOA电路修复难度高等问题,达到确保Gate波形输出、良好Gate波形输出、实现电路自修复功能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

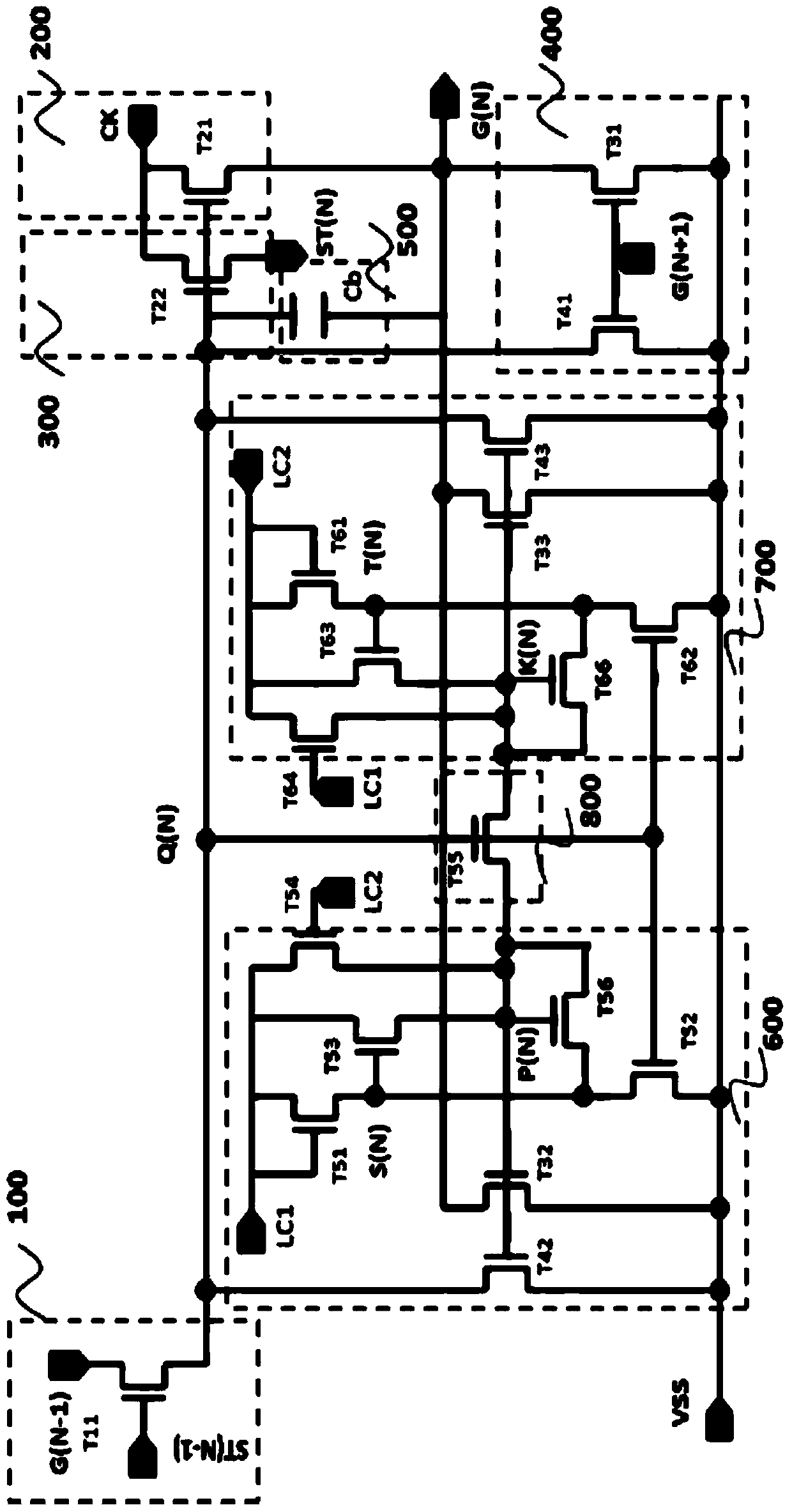

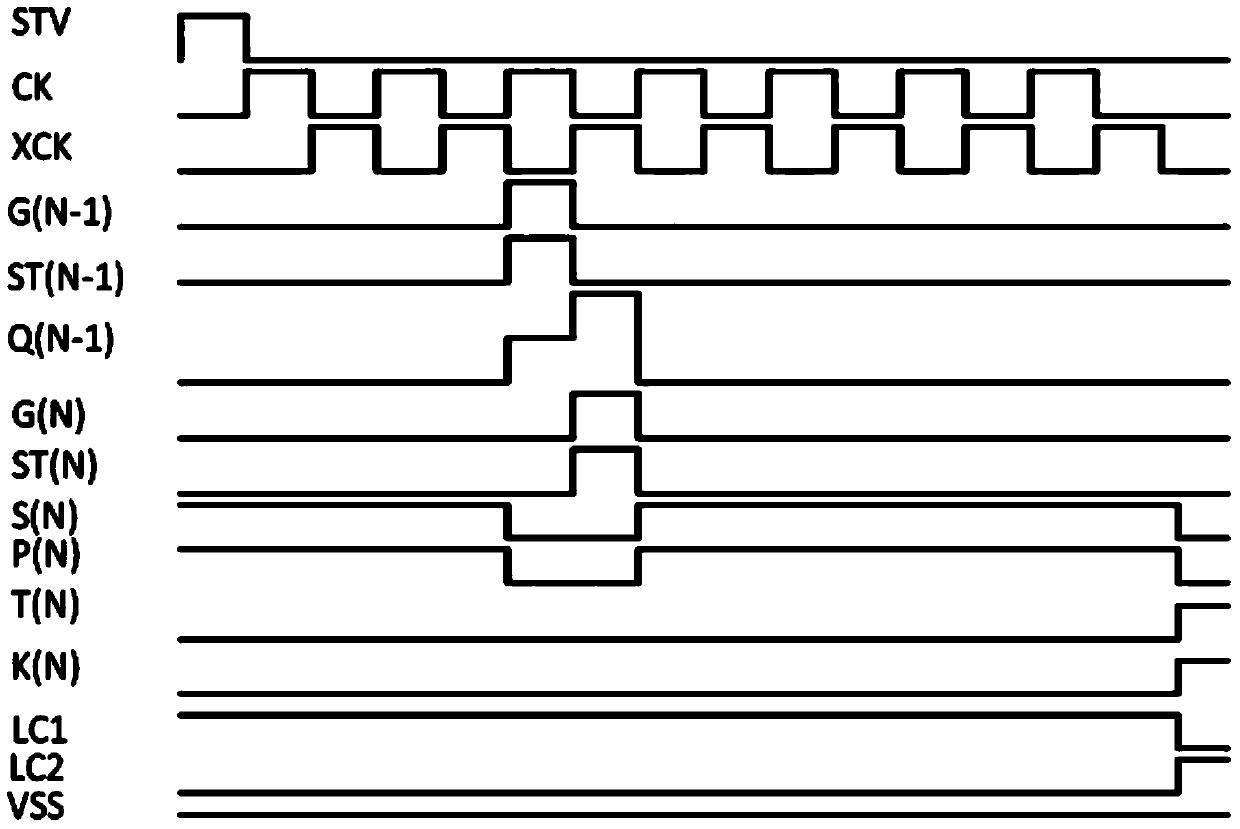

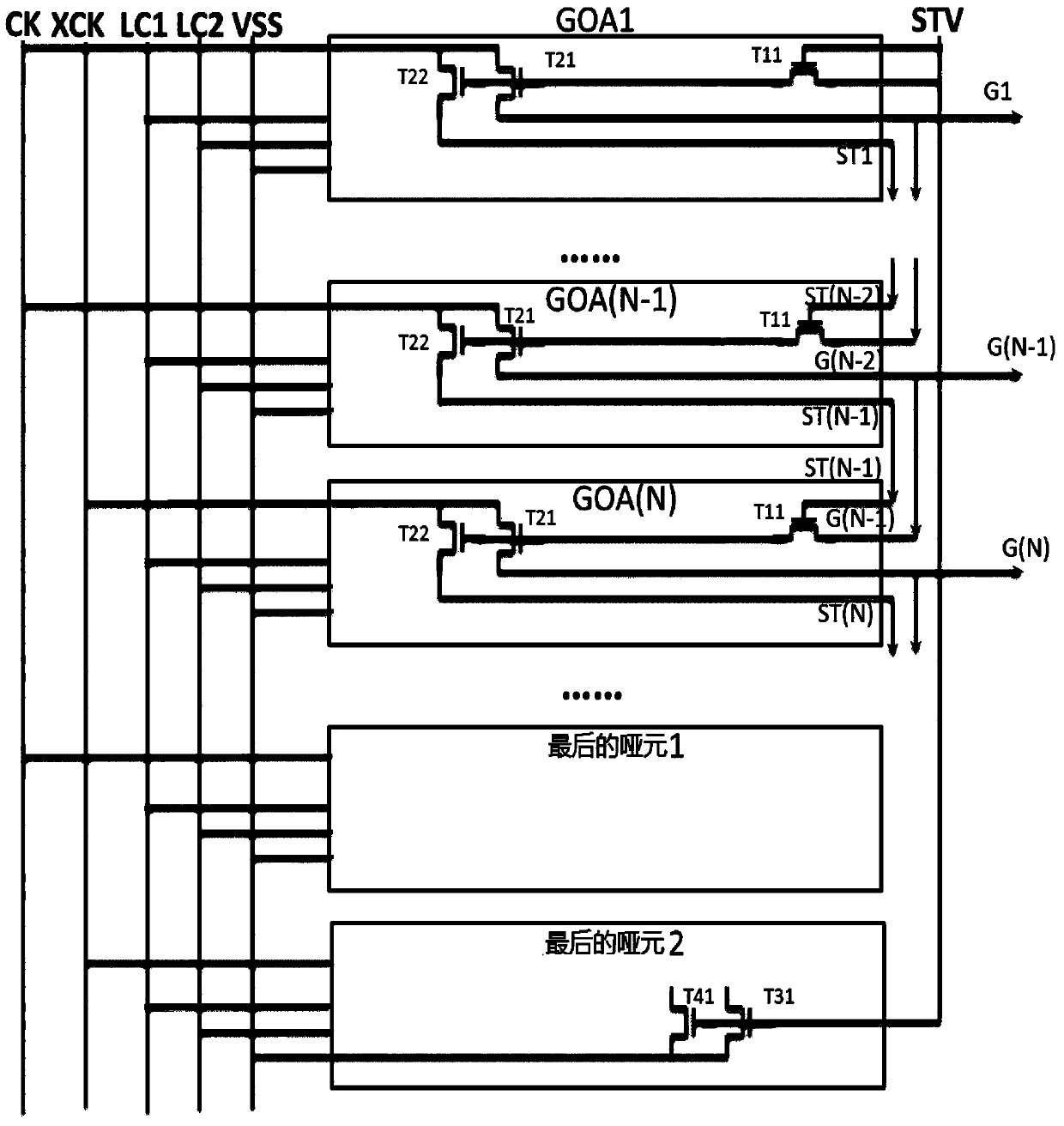

[0045] see figure 1, which is a circuit diagram of an embodiment of the self-repairing gate driving circuit of the present invention. The self-repairing gate drive circuit of the present invention includes a plurality of cascaded GOA units, and charges the Nth level horizontal scan line G(N) in the display area according to the control of the Nth level GOA unit. The Nth level GOA unit includes a pull-up Control circuit 100, pull-up circuit 200, downlink circuit 300, pull-down circuit 400, bootstrap capacitor 500, first pull-down sustaining circuit 600, second pull-down sustaining circuit 700, and bridge circuit 800; the pull-up circuit 200, pull-down The circuit 400, the first pull-down sustaining circuit 600, the second pull-down sustaining circuit 700 and the bootstrap capacitor 500 are respectively connected to the gate signal point Q(N) and the Nth-level horizontal scan line G(N). The pull-up control The circuit 100 and the downlink circuit 300 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com