Preparation method of silicon/graphene nanocomposite material for cathode of lithium ion battery

A nano-composite material, lithium-ion battery technology, applied in graphene, battery electrodes, nanotechnology for materials and surface science, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

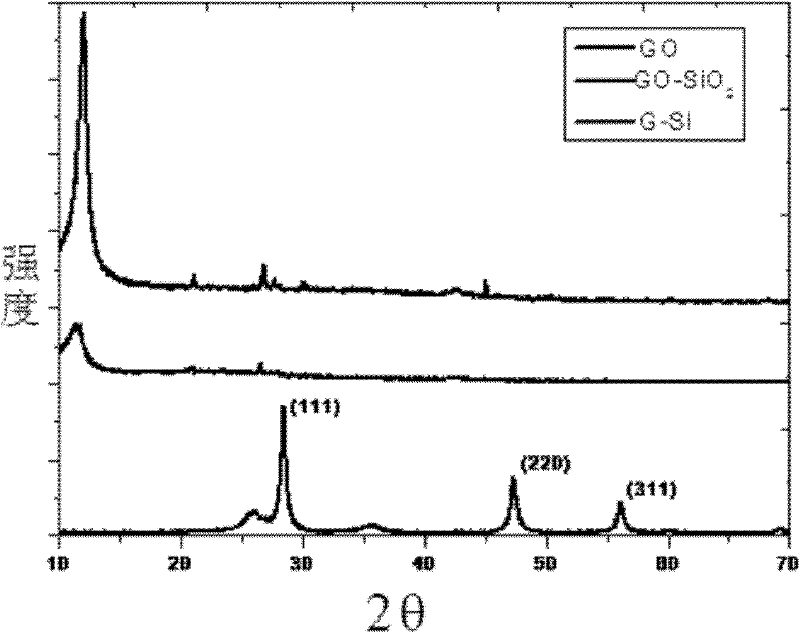

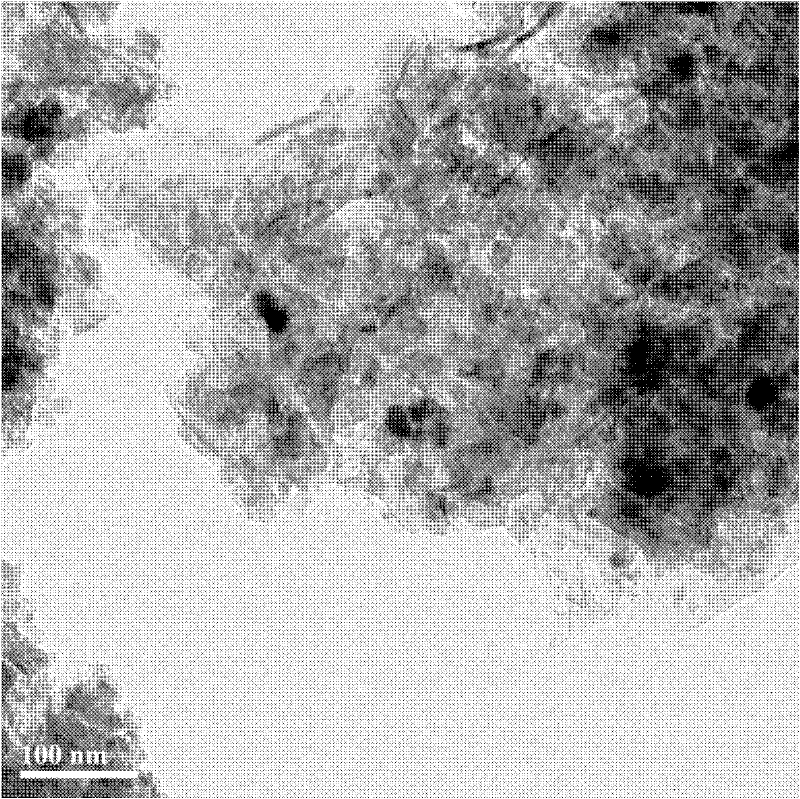

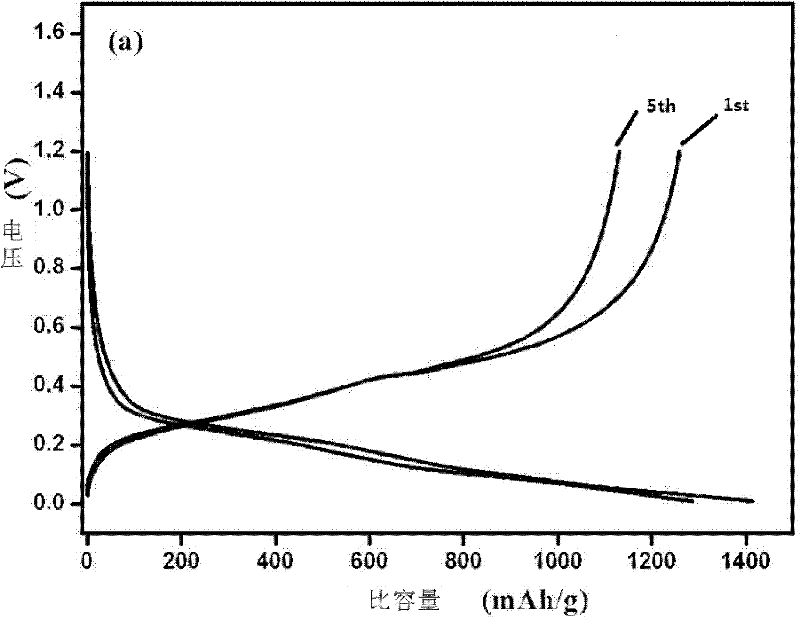

[0032] A method for preparing a silicon / graphene nanocomposite material for a negative electrode of a lithium ion battery, specifically comprising the following steps:

[0033] (1) Under the condition of an ice-water bath, add 2 grams of graphite and 1 gram of sodium nitrate to 50 milliliters of concentrated sulfuric acid, stir for 30 minutes, then slowly add 6 grams of potassium permanganate powder, and keep the temperature of the entire system at 20 ° C and stir About 2 hours, then the temperature was raised to 40°C and kept for 1 hour. Add 90 milliliters of deionized water to the mixture, raise the temperature to 95° C., then dropwise add 20 milliliters of 5% hydrogen peroxide solution, stir evenly, centrifugally filter, and vacuum dry to obtain graphite oxide.

[0034] (2) Get 0.4 gram of graphite oxide prepared in the previous step and add in 78 milliliters of ethanol solution, ultrasonic for 3 hours, add 0.0025 gram of cetyltrimethylammonium bromide, stir for 0.5 hour, a...

Embodiment 2

[0039] A method for preparing a silicon / graphene nanocomposite material for a negative electrode of a lithium ion battery, specifically comprising the following steps:

[0040] (1) the preparation of graphite oxide is with embodiment (1)

[0041] (2) Get 0.3 gram of graphite oxide prepared in the previous step and add in 80 milliliters of ethanol solution, ultrasonic for 3 hours, add 0.003 gram of cetyltrimethylammonium chloride, stir for 1 hour, add 20 milliliters of deionized water and 5 ml of tetraethyl silicate, ultrasonic treatment for 3 hours, adding 5 ml of hydrazine hydrate, stirring at 90°C for 12 hours, washing, filtering, and vacuum drying to obtain a silica / graphene composite material.

[0042] (3) Mix 0.2 grams of silica / graphene composite material with 0.2 grams of magnesium powder, spread evenly on the bottom of the magnetic boat, put the magnetic boat into a quartz tube filled with argon, seal it, and place the quartz tube with the argon Calcined at 750°C for ...

Embodiment 3

[0046] A method for preparing a silicon / graphene nanocomposite material for a negative electrode of a lithium ion battery, specifically comprising the following steps:

[0047] (1) Preparation of graphite oxide: under the condition of an ice-water bath, add 1 gram of graphite and 1 sodium nitrate to 50 ml of concentrated sulfuric acid, stir evenly, slowly add 4 g of potassium permanganate powder, in the process, the temperature of the whole system is controlled Stir between 10°C and heat up to 30°C. 60 ml of deionized water was added dropwise to the above mixed solution, and the temperature was controlled at 90°C. Then 10 ml of 5% hydrogen peroxide solution was added dropwise, stirred evenly, centrifugally filtered, and vacuum-dried to obtain powdered graphite oxide.

[0048] (2) Preparation of silica / graphene oxide composite material: Take 0.2 g of graphite oxide powder and add it to 60 ml of ethanol solution, ultrasonicate for 2 hours, add 0.001 g of cetyltrimethylammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com