Carbon dioxide capture systems and methods

a carbon dioxide and carbon dioxide technology, applied in the field of carbon dioxide capture, can solve the problems of high cost of carbon dioxide capture using current technology, high cost of cosub>2 /sub>capture, etc., and achieve the effect of convenient co2 separation and capture from power plants and more cost effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

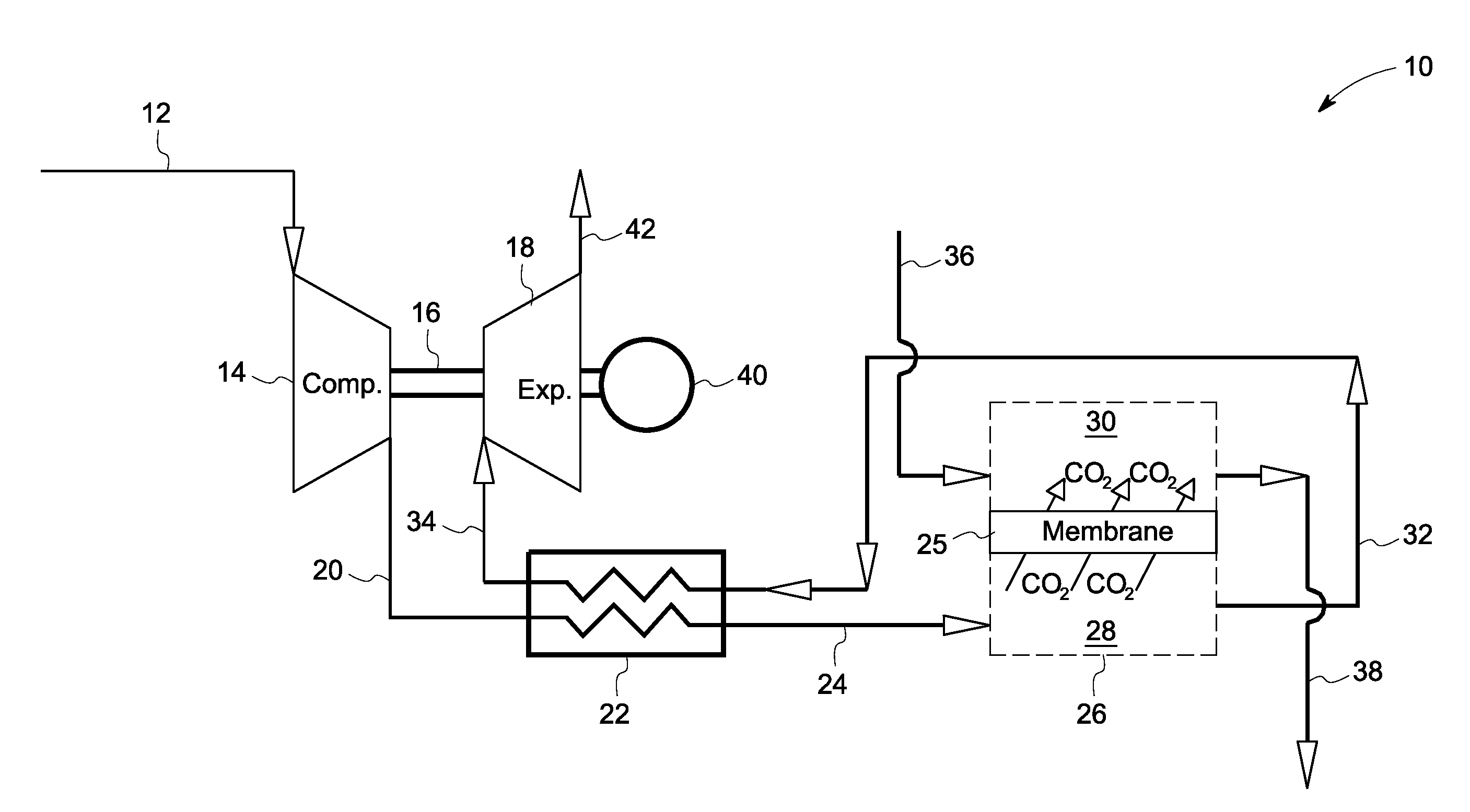

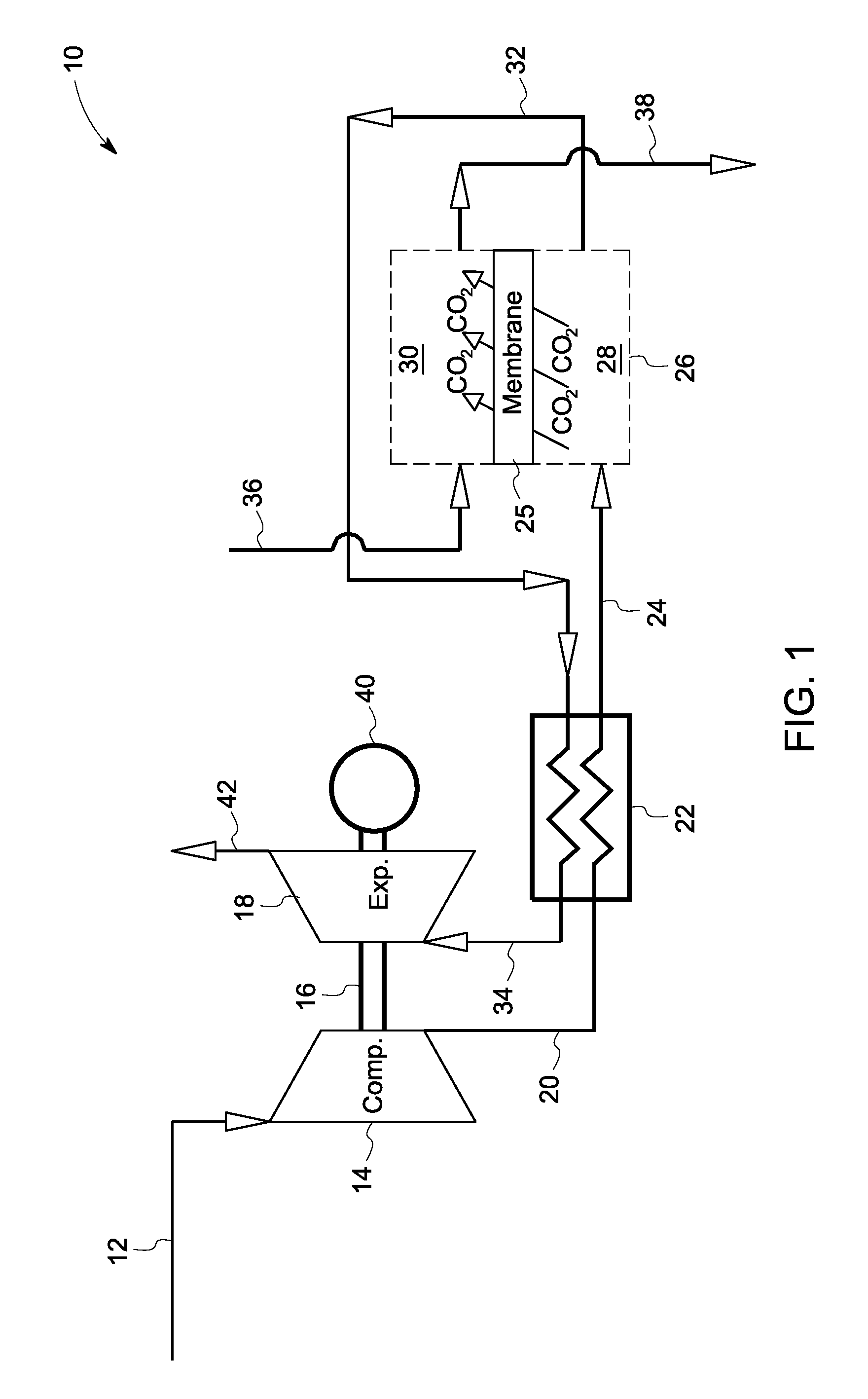

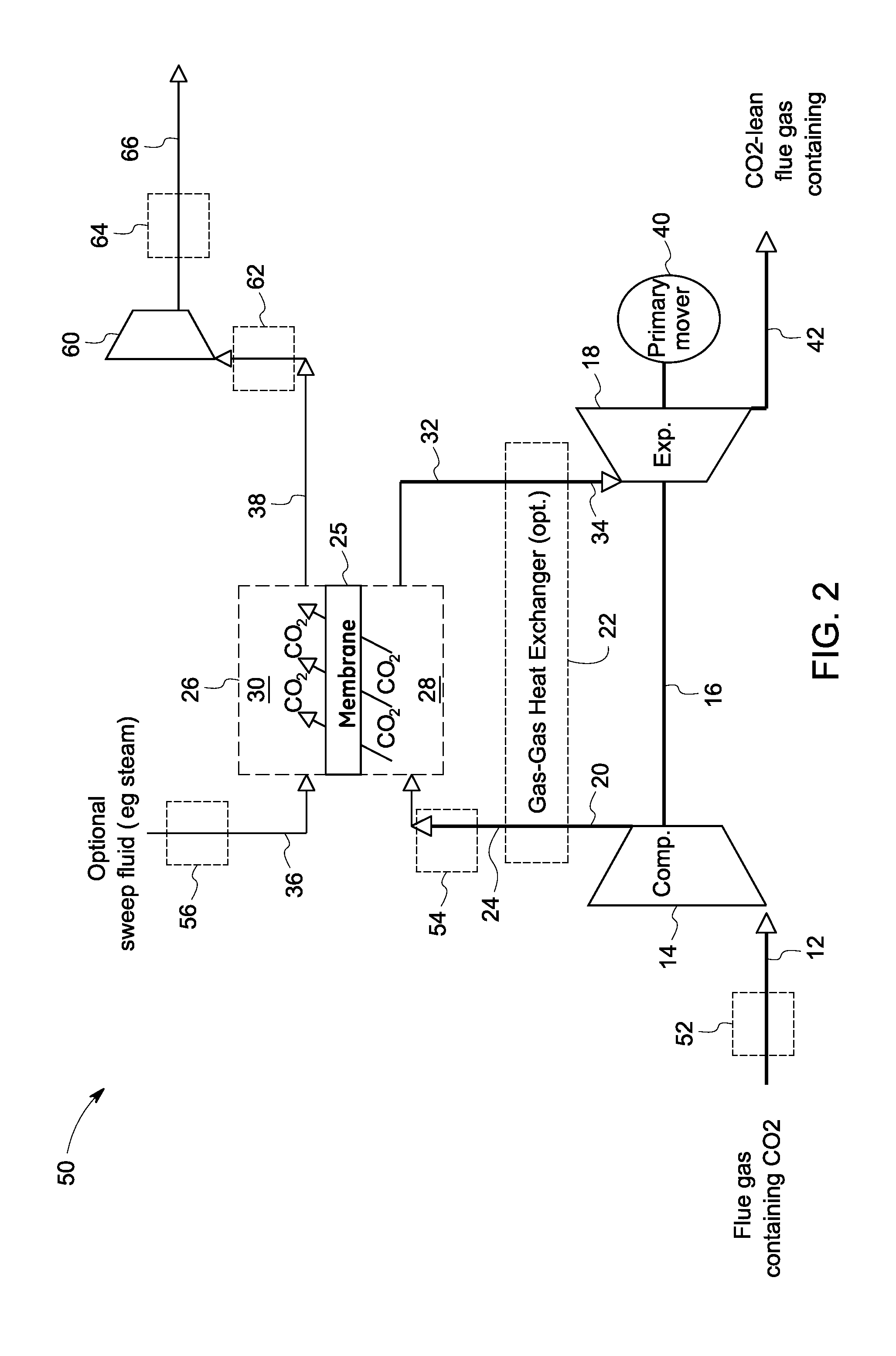

[0017]FIG. 1 illustrates a carbon dioxide (CO2) separation system 10 including a compressor 14 for receiving an exhaust gas 12 comprising CO2 and generating a compressed exhaust gas 20. The separation system 10 also includes a separator 26 configured to receive the compressed exhaust gas 20 and generate a CO2 lean stream 32. The separator 26 includes a first flow path 28 for receiving the compressed exhaust gas 20, a second flow path 30 for directing a sweep fluid 36 therethrough, and a material 25 with selective permeability of carbon dioxide for separating the first and the second flow paths 28 and 30 and for promoting carbon dioxide transport therebetween. The CO2 separation system 10 further includes an expander 18 optionally coupled to the compressor 14 through a common shaft 16 for receiving and expanding the CO2 lean stream 32 to generate power through generator 40 and an expanded CO2 lean stream 42, or reduce the overall power requirement in the compressor-expander section t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com