Control method for coordination and automatic power generation of coal quality self-adaptive thermal power generating unit

A technology of automatic power generation control and thermal power unit, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc. It can solve the problems of fuel change and the unsteady operation of the fuel control system, and achieve stable changes, improved accuracy of controlled parameters, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

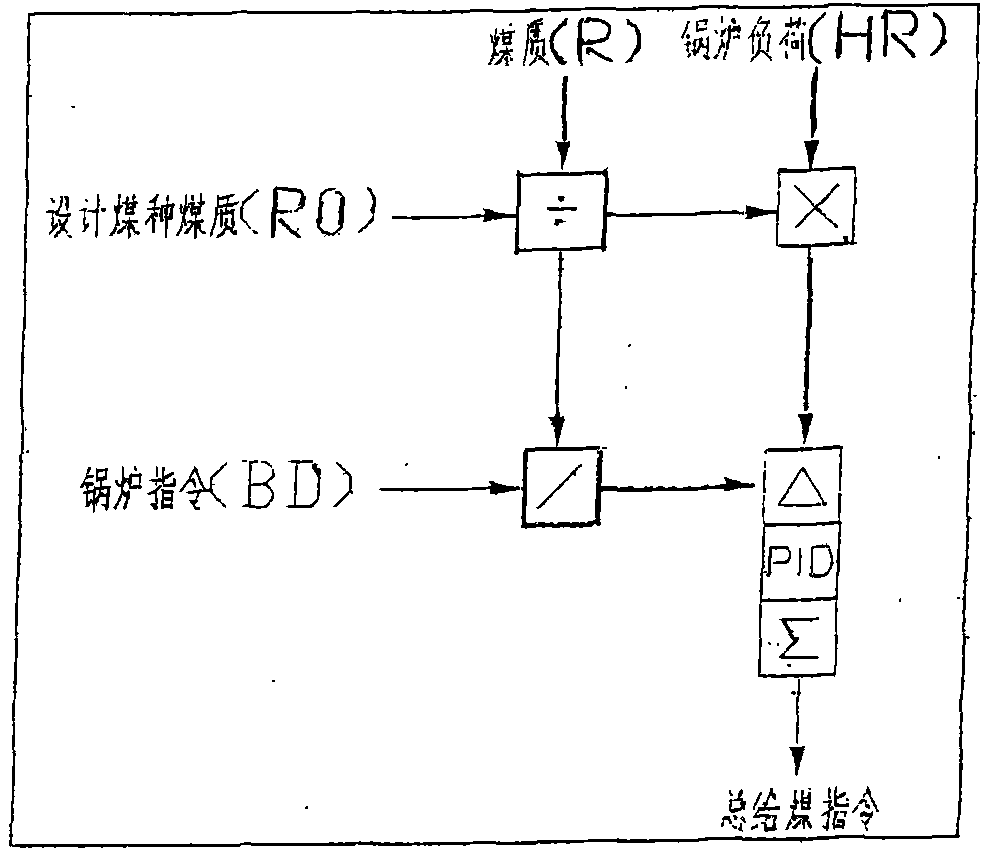

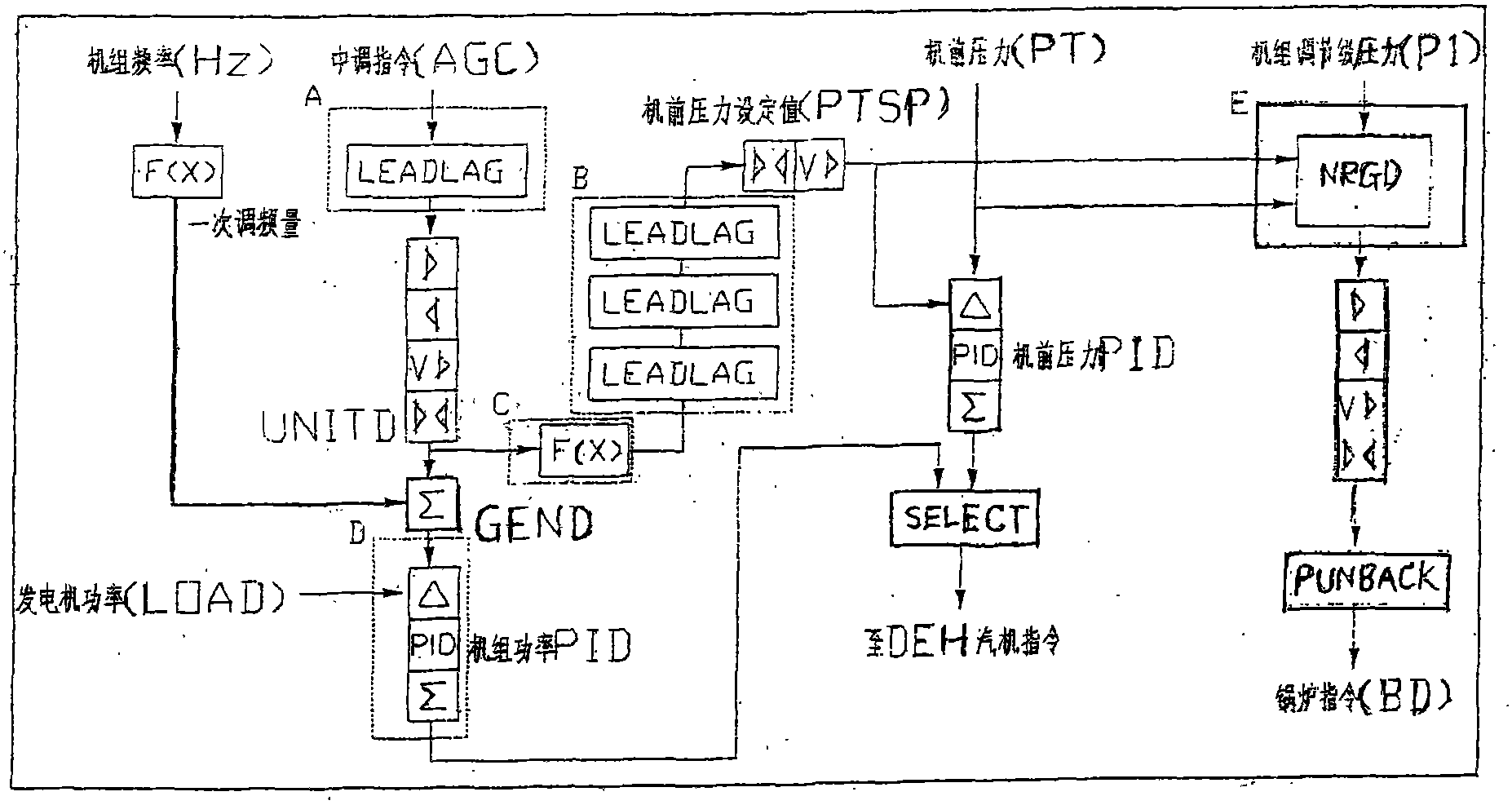

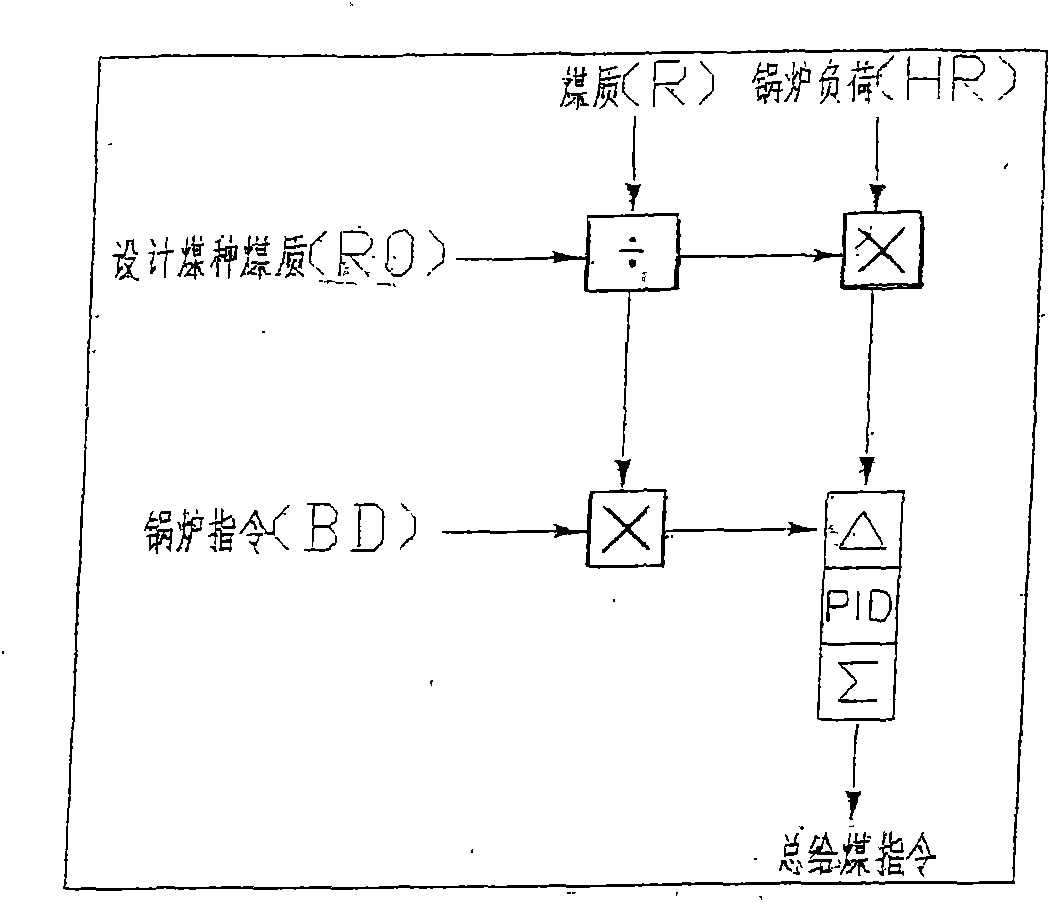

[0064] Coal quality self-adaptive thermal power unit coordination and automatic power generation control method, the method includes the following steps:

[0065] (1) The coal quality is comprehensively calculated from parameters such as the primary pressure of the steam turbine, the pressure of the steam drum, the amount of coal fed, and the load of the unit;

[0066] The coal quality is represented by calculating the filtered value of the ratio of the boiler heat signal to the coal quantity:

[0067] R=Filter(HR / M) (1)

[0068] HR-Heat Release heat signal (MW);

[0069] M-coal supply, t / h;

[0070] Filter-filtering module;

[0071] R-coal quality coefficient;

[0072] The heat signal is calculated using the following formula:

[0073] HR=TEF+C b ·P D ' (2)

[0074] C b - Boiler heat storage coefficient (MW.s / MPa);

[0075] P D '-drum pressure (or boiler steam separator pressure) rate of change (MPa / s);

[0076] TEF-Total Energy Flow total energy flow (MW)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com