Floating belt grinding device with feed back and adjustable pressure

A technology of abrasive belt grinding and pressure, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., which can solve the problems of inability to accurately reflect the change of grinding pressure, difficulty in guaranteeing the quality of the profile, and reduce the grinding process. Accuracy and other issues, to achieve good product consistency, low modification cost, and improve the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

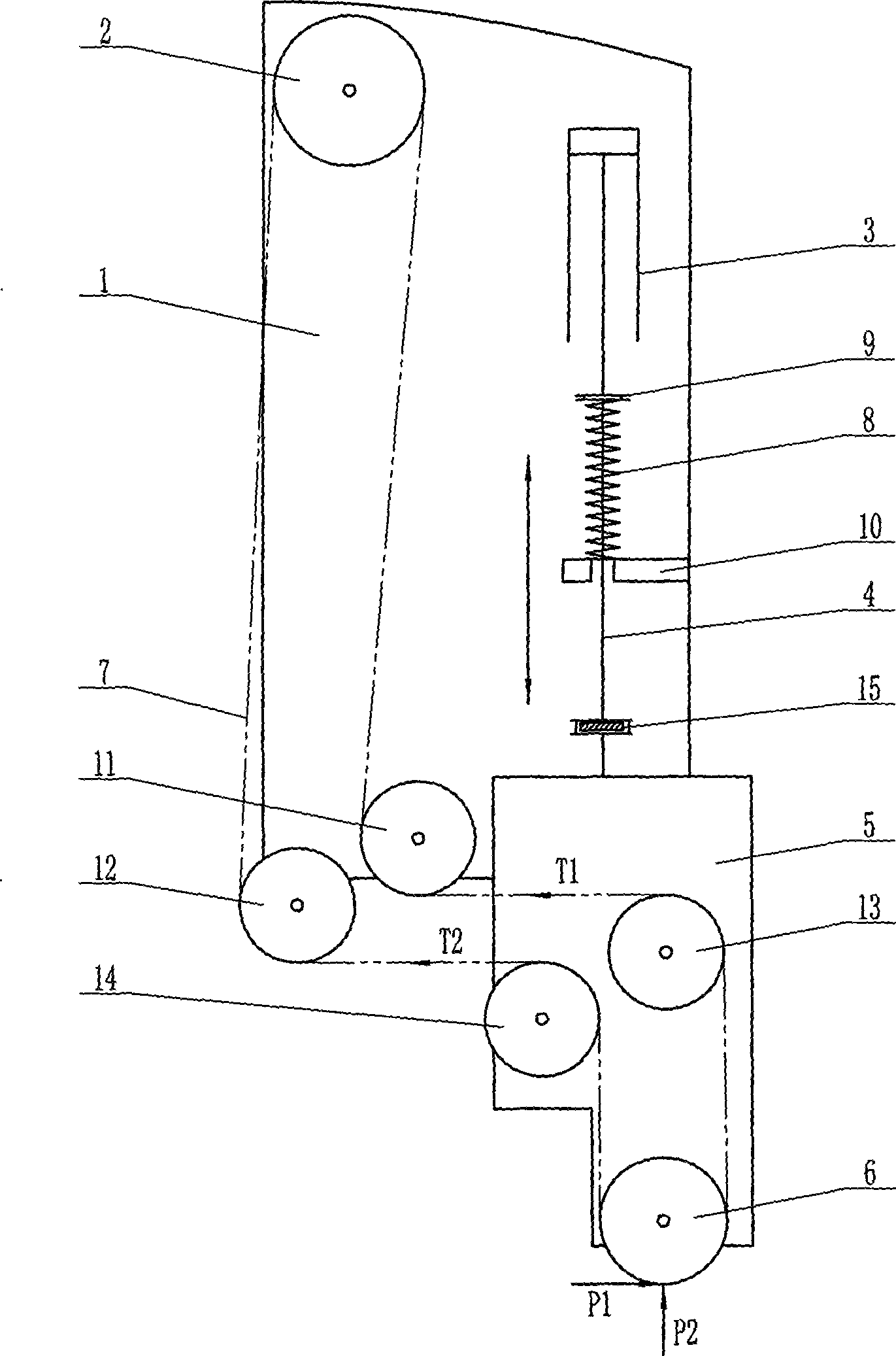

[0014] Such as figure 1 As shown, the present invention consists of a support plate 1, a drive wheel 2, a cylinder 3, a guide post 4, a fine-tuning sliding plate 5, a contact wheel 6, an abrasive belt 7, a spring 8, a nut 9, a baffle plate 10, a first idler wheel 11, The second idle gear 12, the third idle gear 13, the fourth idle gear 14 and the pressure sensor 15 are composed of components. A drive motor (not shown) and a cylinder 3 are installed on the top of the support plate 1, wherein the drive wheel 2 is sleeved on the output shaft of the drive motor. The piston rod of the cylinder 3 is vertically downward, and is fixedly docked with the upper end of the guide post 4 , and the lower end of the guide post 4 passes through the baffle plate 10 and is fixedly connected with the top of the fine-tuning sliding plate 5 . The baffle plate 10 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com