An assembled lightweight partition wall with a built-in filling box and its manufacturing method

A manufacturing method and filling box technology, applied in the direction of walls, sound insulation, insulation layers, etc., can solve the problems of heavy wall body, long construction period, poor integrity of masonry partition walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

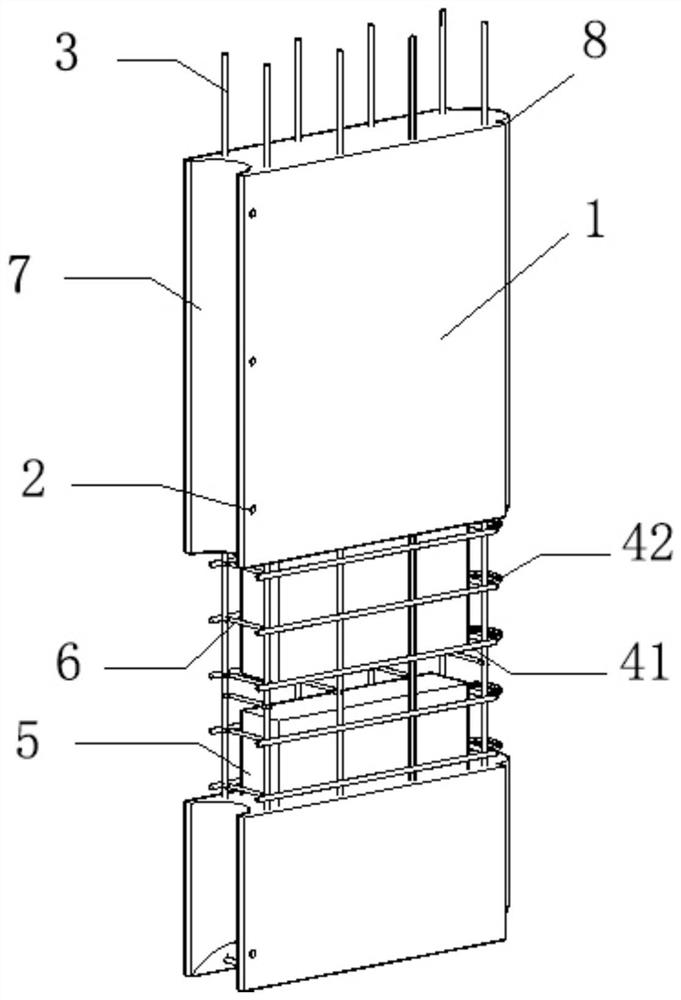

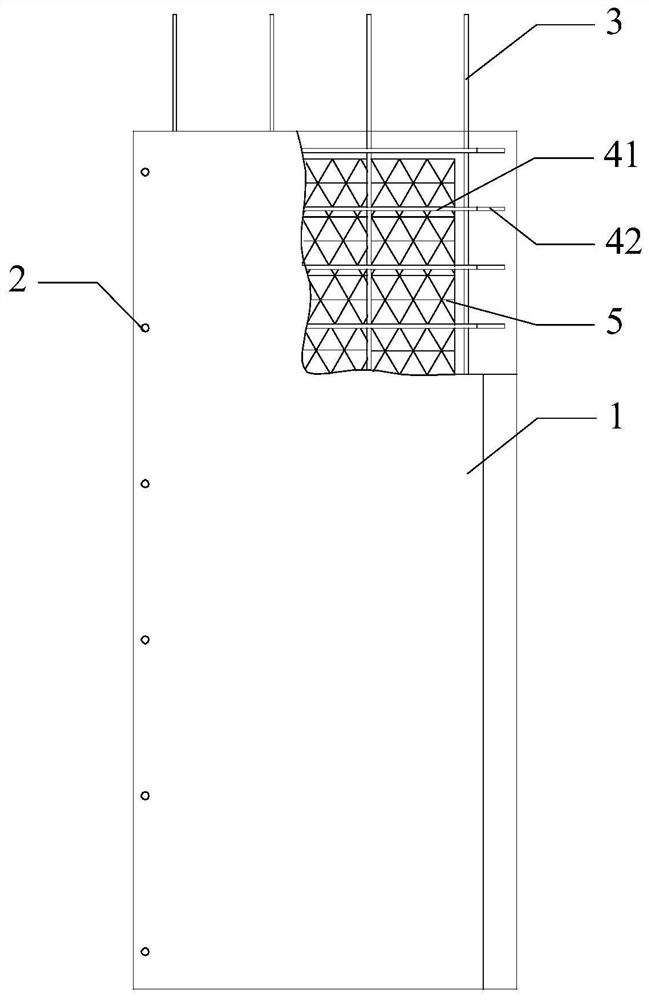

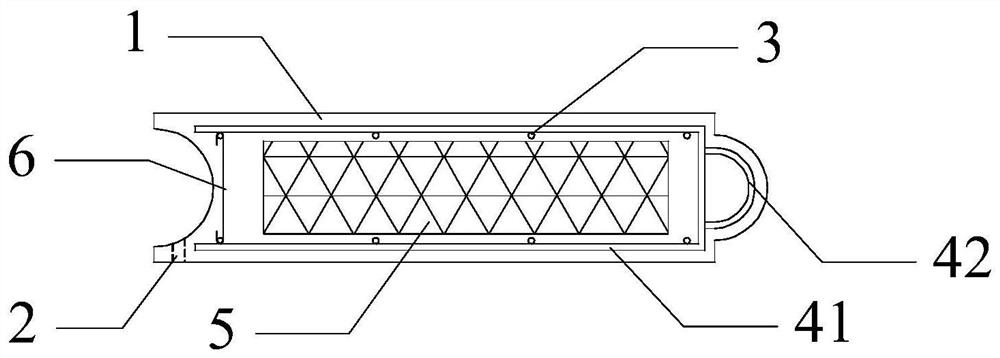

[0031] Attached below Figure 1-5 The present invention will be further described with specific examples. The following examples are only used to illustrate the present invention, but not to limit the scope of the present invention.

[0032] Such as Figure 1-5 As shown, an assembled lightweight partition wall with a built-in filling box of the present invention includes a concrete wall 1 with a built-in filling box. The left and right sides of the concrete wall 1 with a built-in filling box have different structural forms, and one side is a groove 7. The other side is a tenon 8, and the tenon matches the shape of the groove. The bottom of the concrete wall 1 with the built-in filling box is also provided with a groove 7 . The grooves and tenons on both sides of the built-in filling box concrete wall 1 and the grooves on the bottom are semicircular in shape matching each other. A pouring hole 2 is arranged on the wall surface of the groove side of the concrete wall body 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com