Internal combustion directly-heating steam engine

A steam engine and direct heating technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of heat energy loss and low efficiency of steam engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

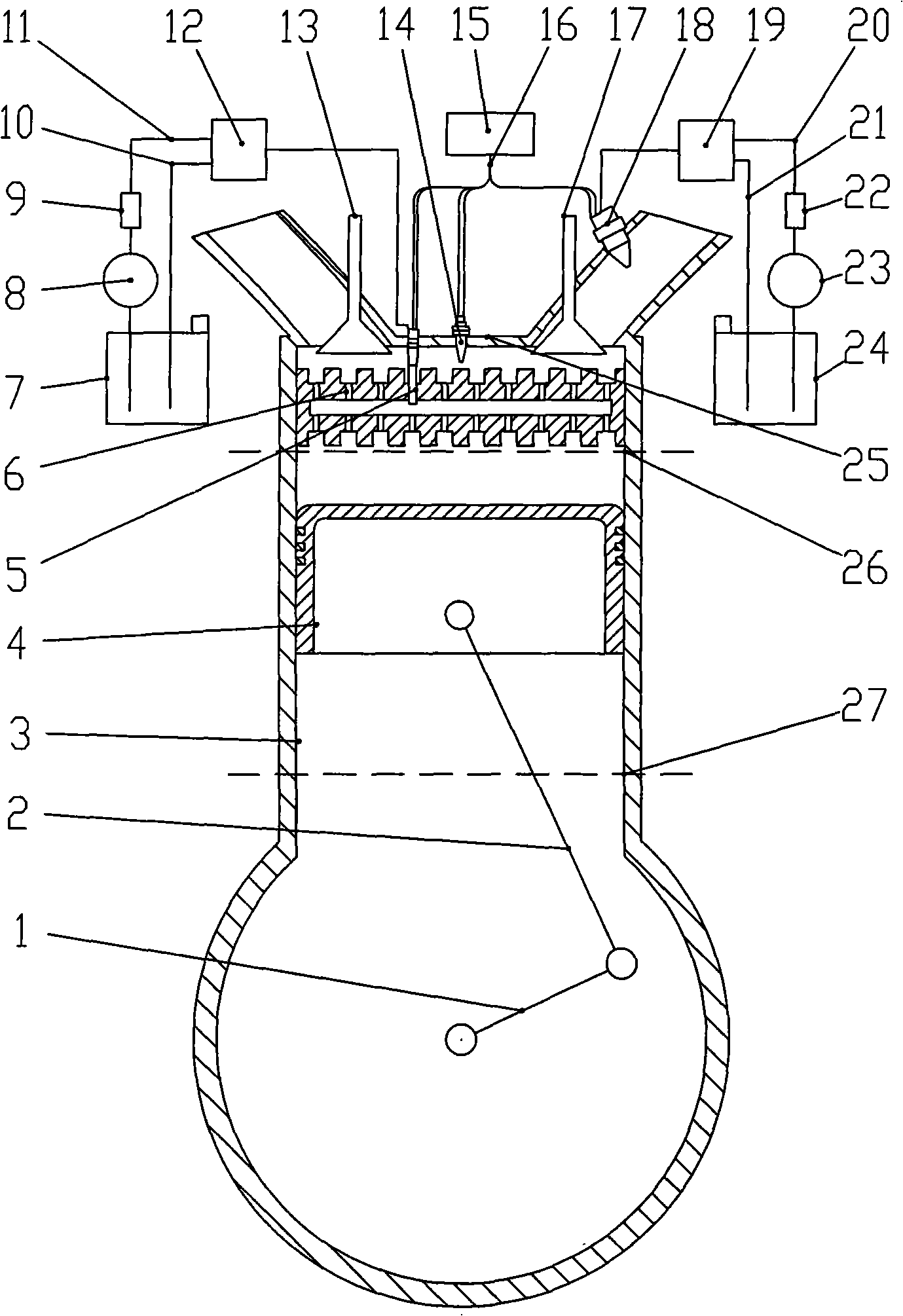

[0016] Embodiment 1 Four-stroke internal combustion direct heating steam engine

[0017] The principle structure of the four-stroke internal combustion direct heating steam engine is as follows: figure 1 shown in figure 1 Among them, the crankshaft 1 is connected with the connecting rod 2, the connecting rod is connected with the piston 4, the piston is set in the cylinder 3, the water sprayer 5 is set on the cylinder head 25, the water sprayer is connected with the water pressure regulator 12, and the water tank 7 is transmitted through the The water pipe 11 is connected to the water pressure regulator, and the high-pressure water pump 8 and the water filter 9 are connected in series on the water delivery pipeline between the water tank and the water pressure regulator. Above, the oil pressure regulator 19 is connected to the fuel tank 24 through the oil delivery pipe 20, a gasoline filter and a high-pressure oil pump 23 are connected in series between the oil pressure regul...

Embodiment 2

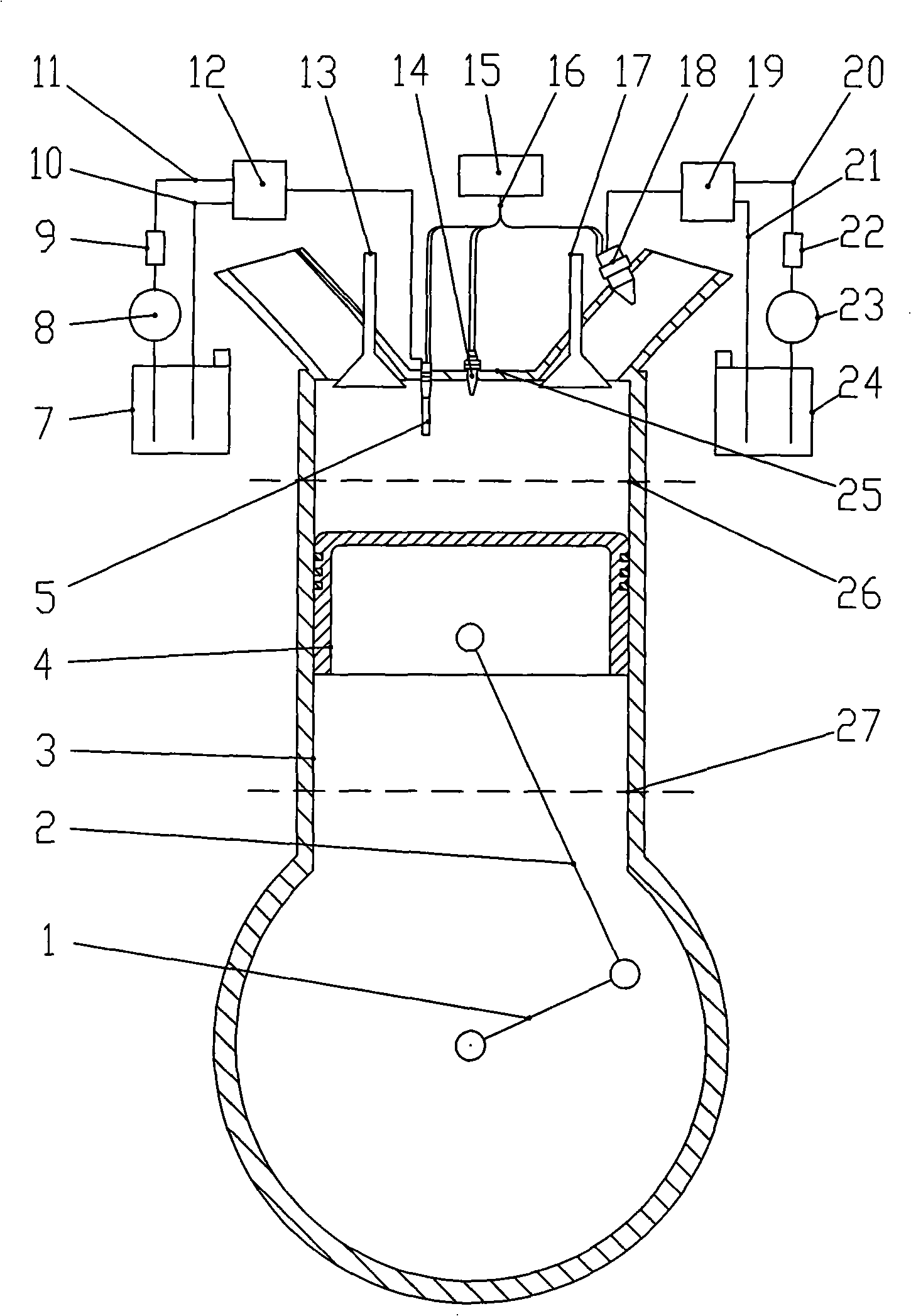

[0026] Embodiment 2 Simple four-stroke internal combustion direct heating steam engine

[0027] Simple four-stroke internal combustion direct heating steam engine such as figure 2 As shown, the simple four-stroke internal combustion direct heating steam engine is in figure 1 On the basis of the heat storage vaporizer, in the power stroke, when the gas is completely combusted, the water jet injects water into the cylinder, the high-temperature gas in the cylinder and the high-temperature cylinder wall vaporize the water, and the steam pushes the piston to do work and output mechanical energy . Without a heat storage vaporizer, the structure is simple, but the thermal efficiency is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com