Internal combustion steam thermal engine

A heat engine, internal combustion steam technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of not considering the fuel ignition conditions, service life, unburned, etc., to reduce rough combustion or The effect of knocking phenomenon, improving low temperature starting ability, and sufficient fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

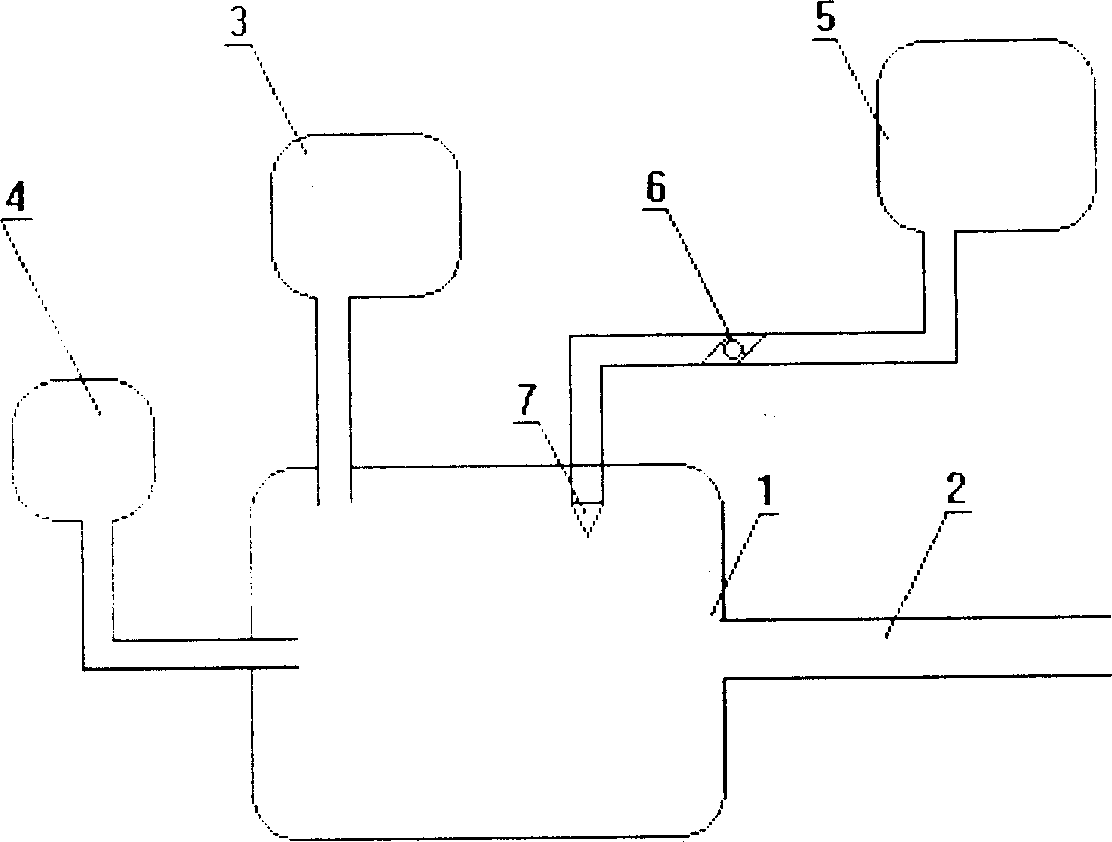

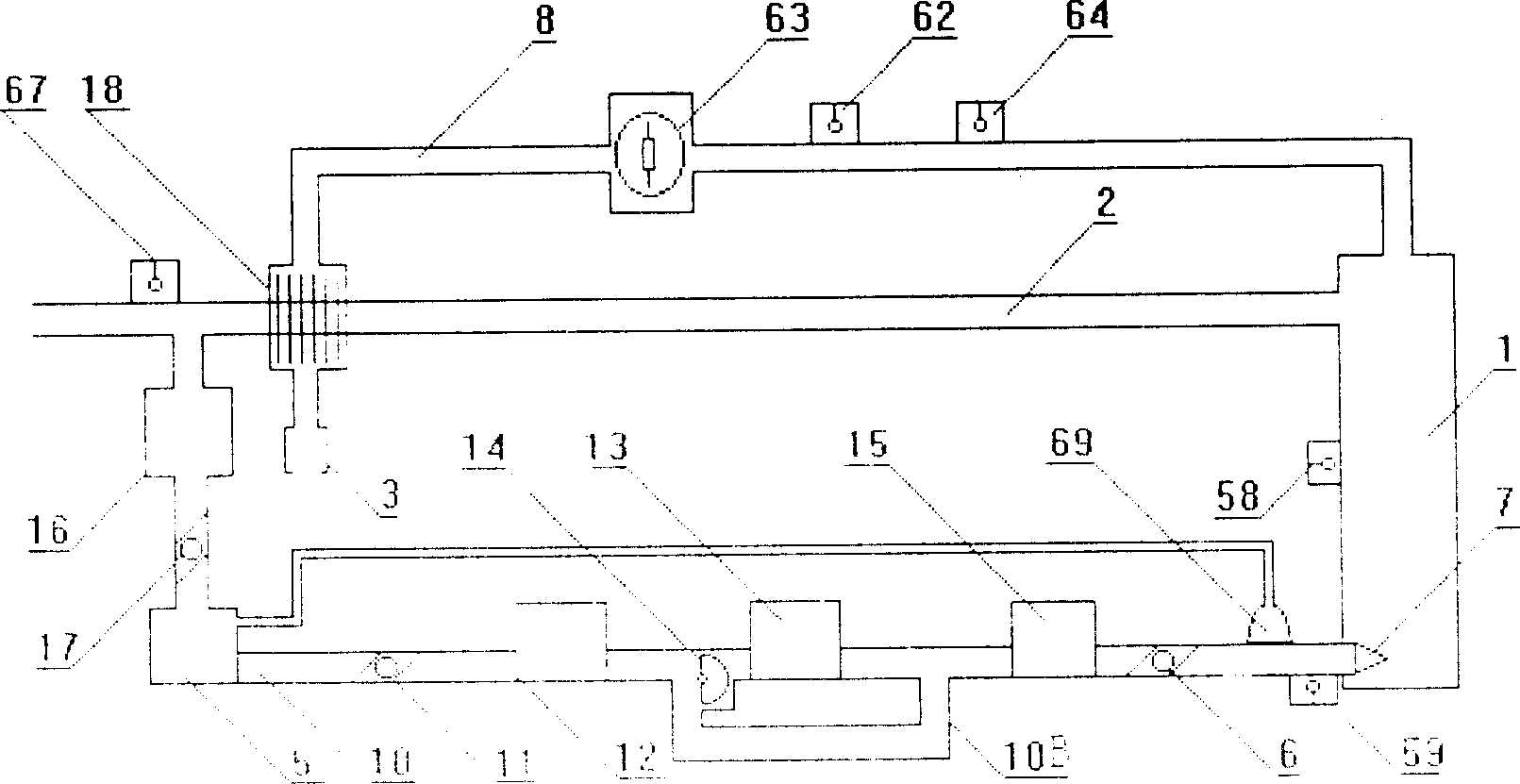

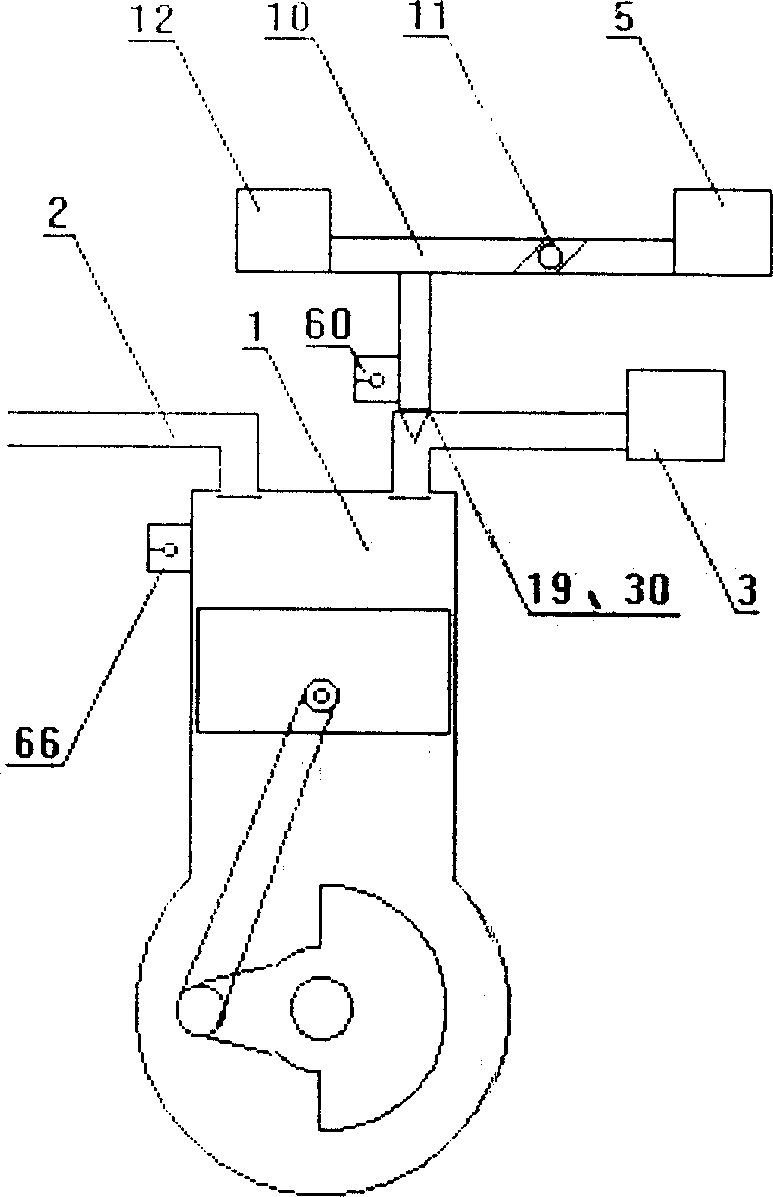

[0035] Depend on figure 1 It can be seen that the internal combustion steam engine of the present invention is based on the existing engine main body (not drawing power output parts such as pistons, rotors, gas wheels, etc.) generated by the expansion of high-temperature exhaust gas after fuel combustion, except retaining the original Combustion chamber 1 on the engine, exhaust pipe (or exhaust port) 2, air (oxygen) gas source (or air filter) 3, fuel source 4 and other components, and remove various parts for heat dissipation, and then Install water storage tank 5, high-pressure water pump 6 and install high-pressure sprinkler 7 to form on combustion chamber. The high-pressure water injector 7 is installed in the position that the water of spraying both does not affect the normal combustion of the fuel in the combustion chamber 1, and can make the water of spraying absorb the heat energy that the fuel combustion produces rapidly and gasify instantly. When the engine is workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com