A maskless fabrication method for multilayer film capacitors

A multi-layer film and capacitor technology, applied in the direction of film/thick film capacitors, multilayer capacitors, fixed capacitor electrodes, etc., can solve the problems of high process control requirements, high cost, low efficiency, etc., and reduce the production process and cost. Low, simple process control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as the above-mentioned invention patent, the specific implementation steps are as follows:

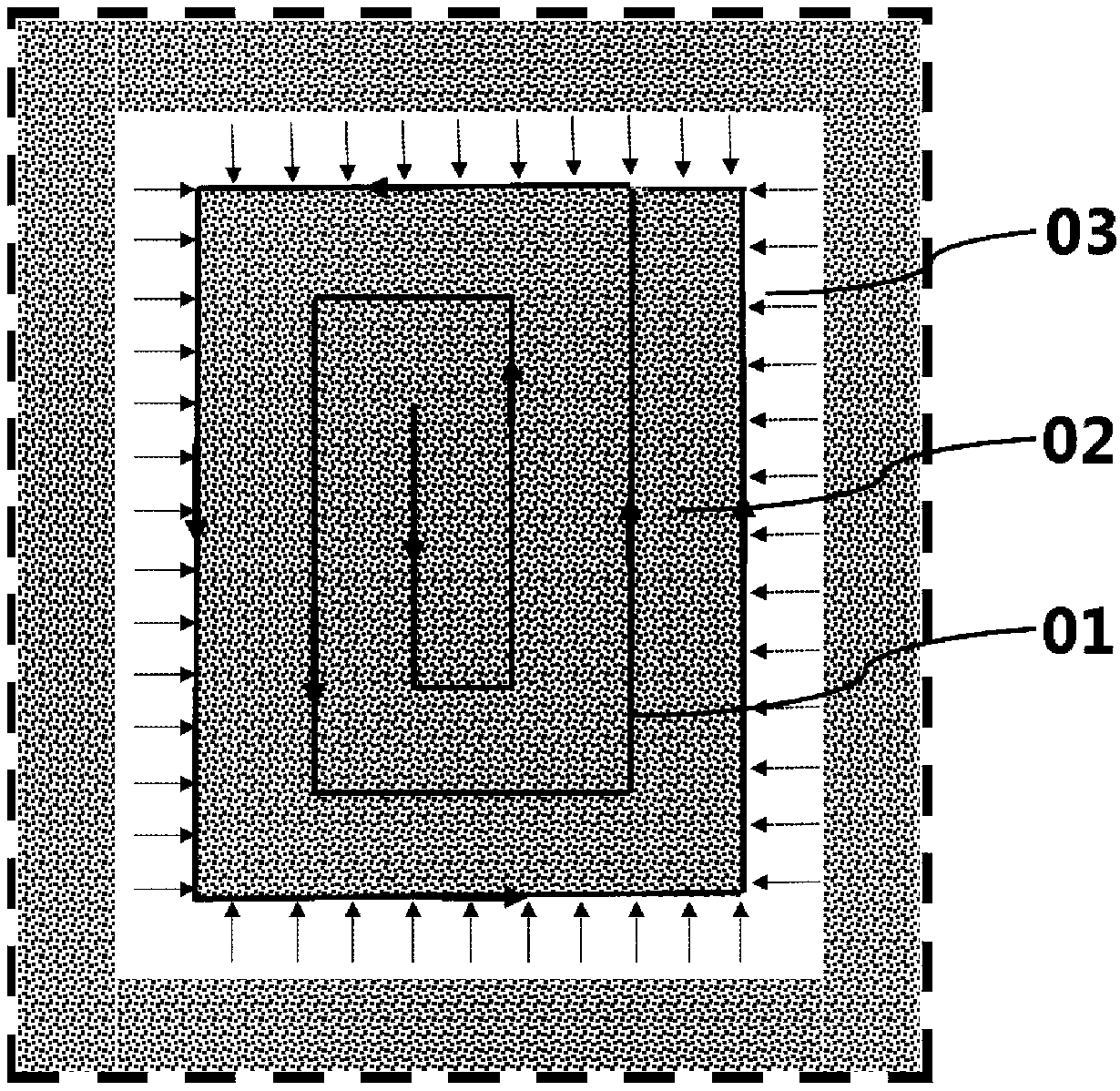

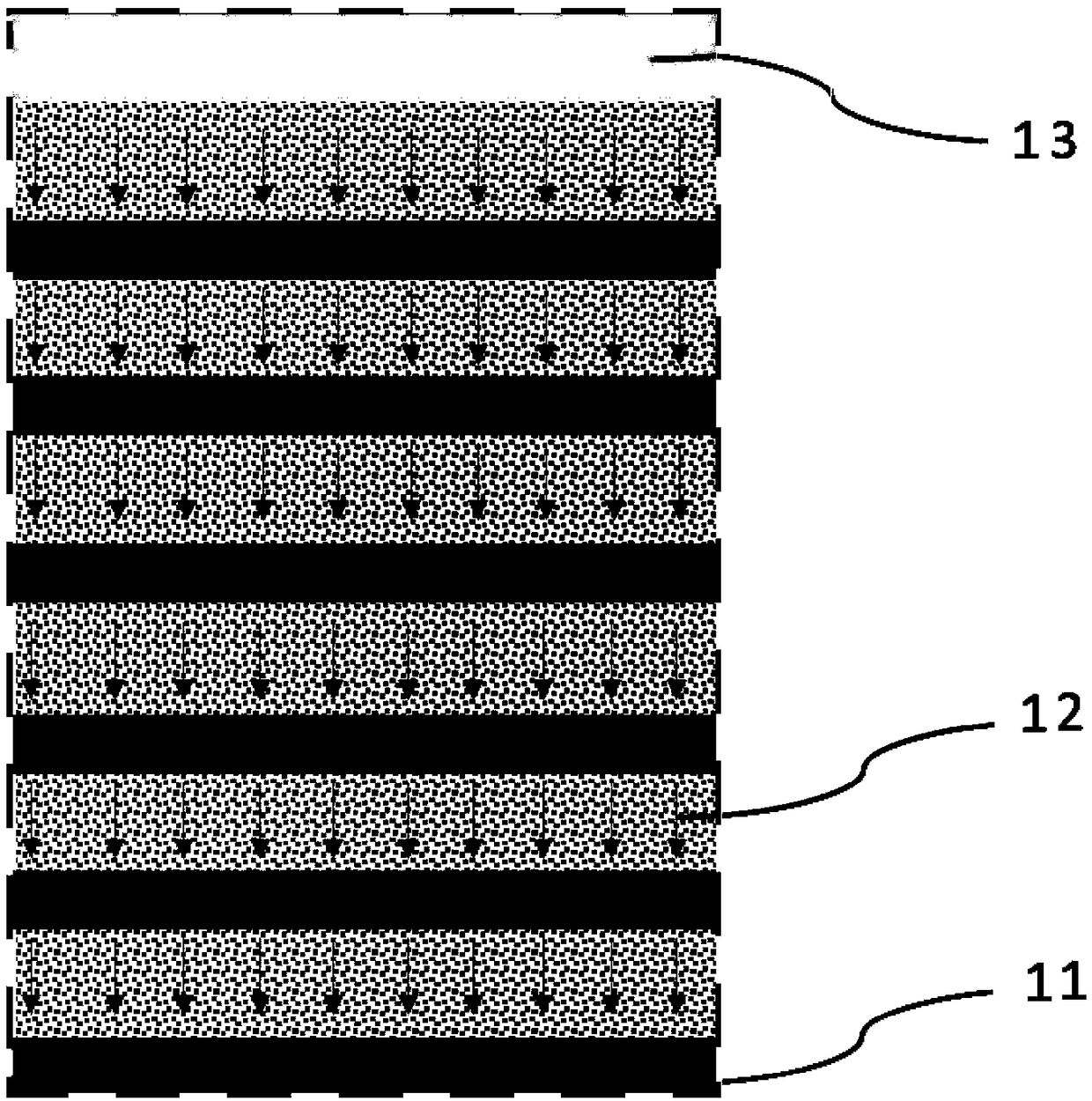

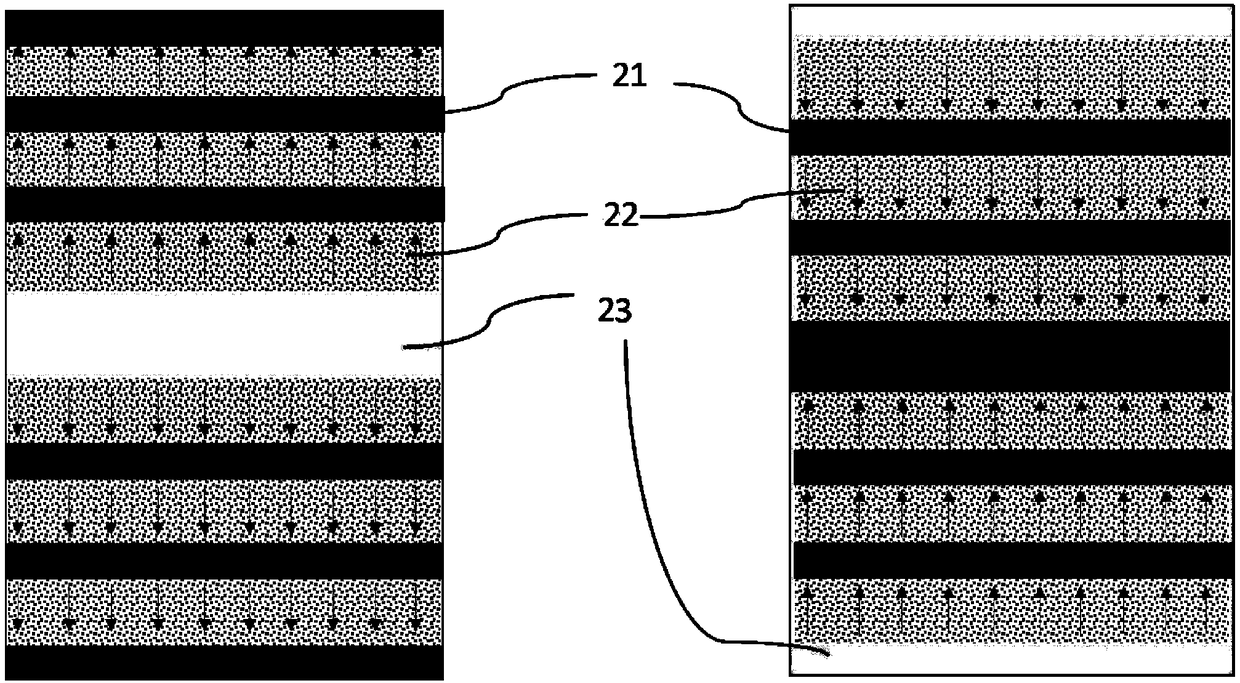

[0033] (1) The metal Ag powder with an average particle size of 50nm is prepared into a slurry according to metal powder: epoxy resin = 50:50 (mass percentage), and then the electrode layer with a thickness of 200nm is prepared on the alumina ceramic substrate, Then, a square infrared spot with a side length of 0.05 mm at 90°C was used to press the figure 1 The method shown is to carry out directional scanning heating on the surface of the film. The length and width of the directional scanning heating area are 0.2×0.1 mm. Finally, a laser beam with a temperature of 550 ° C, a line width of 30 μm, and a length of 0.1 mm is used to press the figure 2 In the shown manner, the thin film is heated directionally, and finally the metal electrode is formed into the desired electrode pattern.

[0034] (2) Using butyl titanate, barium acetate, glacial acetic acid and acetylacetone ...

Embodiment 2

[0038] (1) The metal Ni powder with an average particle size of 20nm is prepared into a slurry according to metal powder: epoxy resin = 60:40 (mass percentage), and then an electrode layer with a thickness of 100nm is prepared on a quartz substrate, and then A circular infrared spot with a diameter of 0.03mm at 50°C is used to press the figure 1 The method shown is to carry out directional scanning heating on the surface of the film. The length and width of the directional scanning heating area are 0.4×0.2 mm. Finally, a laser beam with a temperature of 450 ° C, a line width of 10 μm, and a length of 0.2 mm is used to press figure 2 In the shown manner, the thin film is heated directionally, and finally the metal electrode is formed into the desired electrode pattern.

[0039] (2) Using butyl titanate, barium acetate, glacial acetic acid, acetylacetone, zirconium acetate and other raw materials according to the ratio of Y5V porcelain powder, prepare a sol with a metal ion dep...

Embodiment 3

[0043](1) The metal Cu powder with an average particle size of 200nm was prepared into a slurry according to metal powder: epoxy resin = 65:35 (mass percentage), and then the electrode layer with a thickness of 500nm was prepared on a silicon wafer, and then A circular infrared spot with a diameter of 0.05mm at 150°C is used to press the figure 1 The method shown is for directional scanning heating on the surface of the film. The length and width of the directional scanning heating zone are 0.6×0.3. figure 2 In the shown manner, the thin film is heated directionally, and finally the metal electrode is formed into the desired electrode pattern.

[0044] (2) Using butyl titanate, barium acetate, glacial acetic acid, acetylacetone, zirconium acetate and other raw materials according to the ratio of Y5V porcelain powder, prepare a sol with a metal ion depth of 0.2mol / L, and prepare it on the above patterned electrode substrate through several A Y5V dielectric film with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com