A kind of preparation method of carbon dots/chitosan in situ composite material

An in-situ composite material and chitosan technology, applied in the direction of luminescent materials, chemical instruments and methods, electrolytic organic material coating, etc., can solve the problems of prolonging the production cycle, increasing equipment and operation steps, increasing production costs, etc., to achieve Simplified post-processing, a wide range of subsequent applications, and short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of carbon dot / chitosan in situ composite material, it comprises following specific steps:

[0037] 1) Preparation of chitosan solution: Add chitosan to distilled water to obtain a chitosan dispersion with a mass concentration of 2.5g / 100mL, then adjust its pH to 4.86 with 0.8M hydrochloric acid solution, 25 o Under magnetic stirring for 9 hours at C, the chitosan is fully dissolved, and its pH is adjusted to 5.60 with 0.8M sodium hydroxide solution to obtain a chitosan solution;

[0038] 2) Preparation of carbon dots / chitosan in situ composite: Take 12 mL of the chitosan solution obtained in step 1), add it to a beaker, and then put it into a household microwave oven with a power of 700W for microwave reaction; the microwave reaction time is 5 minutes , after the reaction is finished, take out the microwave reaction product after natural cooling, then add 24mL distilled water to the microwave reaction product, 25 o After 10 hours of magneti...

Embodiment 2

[0047] A kind of preparation method of carbon dot / chitosan in situ composite material, it comprises following specific steps:

[0048] 1) Preparation of chitosan solution: Add chitosan to distilled water to obtain a chitosan dispersion with a mass concentration of 3.0g / 100mL, then adjust its pH to 5.00 with 1.0M hydrochloric acid solution, 30 o Under magnetic stirring for 10 hours at C, the chitosan was fully dissolved, and its pH was adjusted to 6.00 with 1.0M sodium hydroxide solution to obtain a chitosan solution;

[0049] 2) Preparation of carbon dots / chitosan in situ composite: Take 15 mL of the chitosan solution obtained in step 1), add it to a beaker, and then put it into a household microwave oven with a power of 700W for microwave reaction; the microwave reaction time is 6 minutes , after the reaction is finished, take out the microwave reaction product after natural cooling, then add 30mL distilled water to the microwave reaction product, 30 o After 12 hours of magn...

Embodiment 3

[0058] A kind of preparation method of carbon dot / chitosan in situ composite material, it comprises following specific steps:

[0059] 1) Preparation of chitosan solution: Add chitosan to distilled water to obtain a chitosan dispersion with a mass concentration of 2.0g / 100mL, then adjust its pH to 4.50 with 0.5M hydrochloric acid solution, 20 o Under magnetic stirring for 8 hours at C, the chitosan was fully dissolved, and its pH was adjusted to 5.50 with 0.5M sodium hydroxide solution to obtain a chitosan solution;

[0060] 2) Preparation of carbon dots / chitosan in situ composite: Take 10 mL of the chitosan solution obtained in step 1), add it to a beaker, and then put it into a household microwave oven with a power of 700W for microwave reaction; the microwave reaction time is 4 minutes , after the reaction is finished, take out the microwave reaction product after natural cooling, then add 20mL distilled water to the microwave reaction product, 20 o After 8 hours of magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

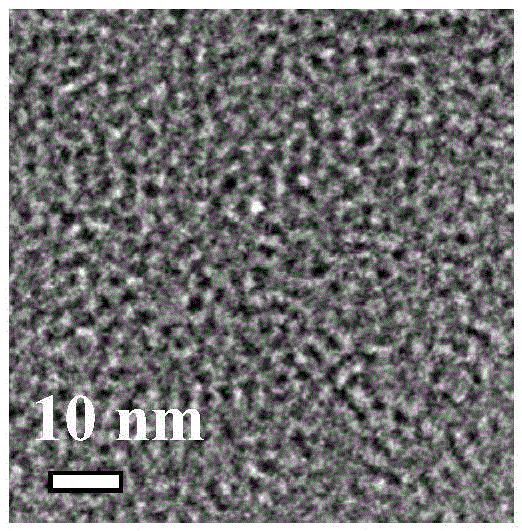

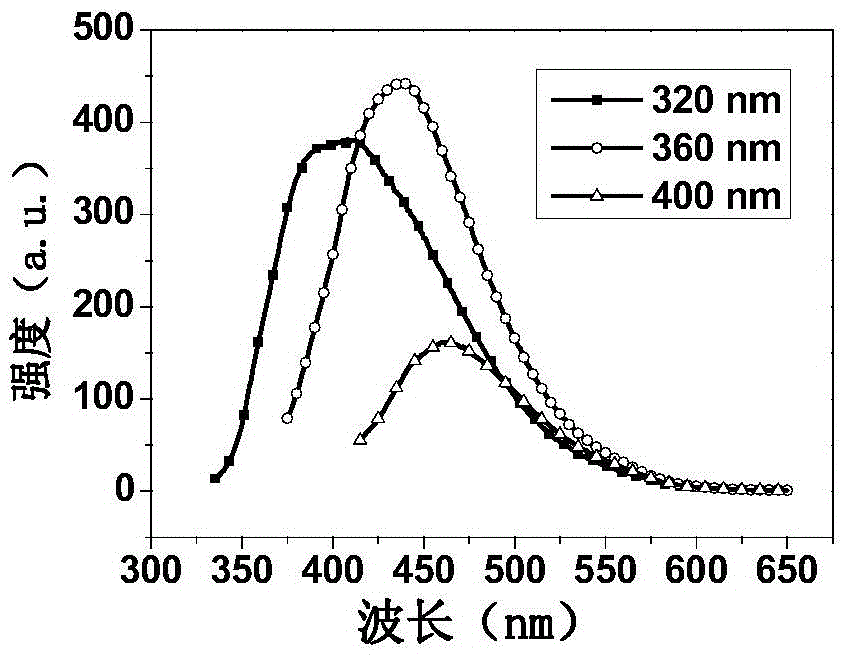

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com