Lightweight high strength waterproof door

A high-strength waterproof door technology, which is applied in the direction of door leaves, windows/doors, building components, etc., can solve the problems of complex waterproof door forming process, inconvenient installation and transportation, and inconvenient industrial production, so as to meet the structural strength requirements and reduce the cost. The effect of manufacturing process and material reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

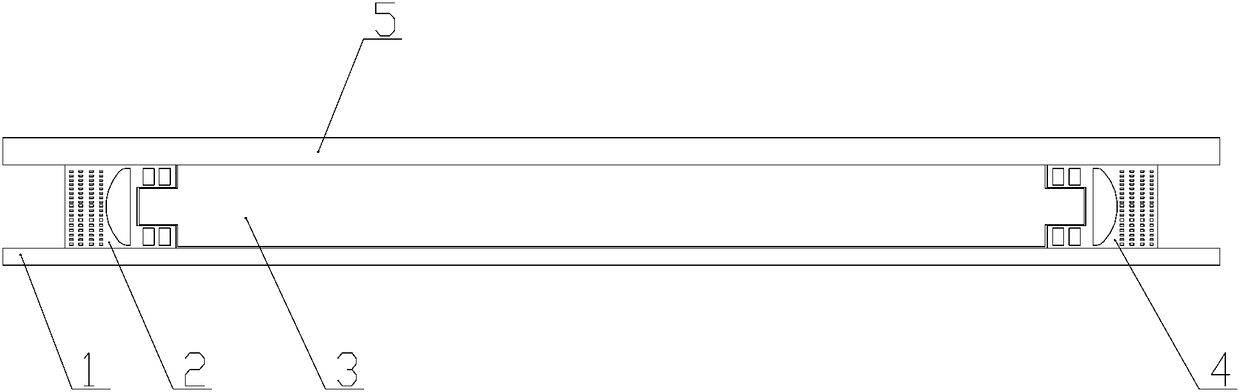

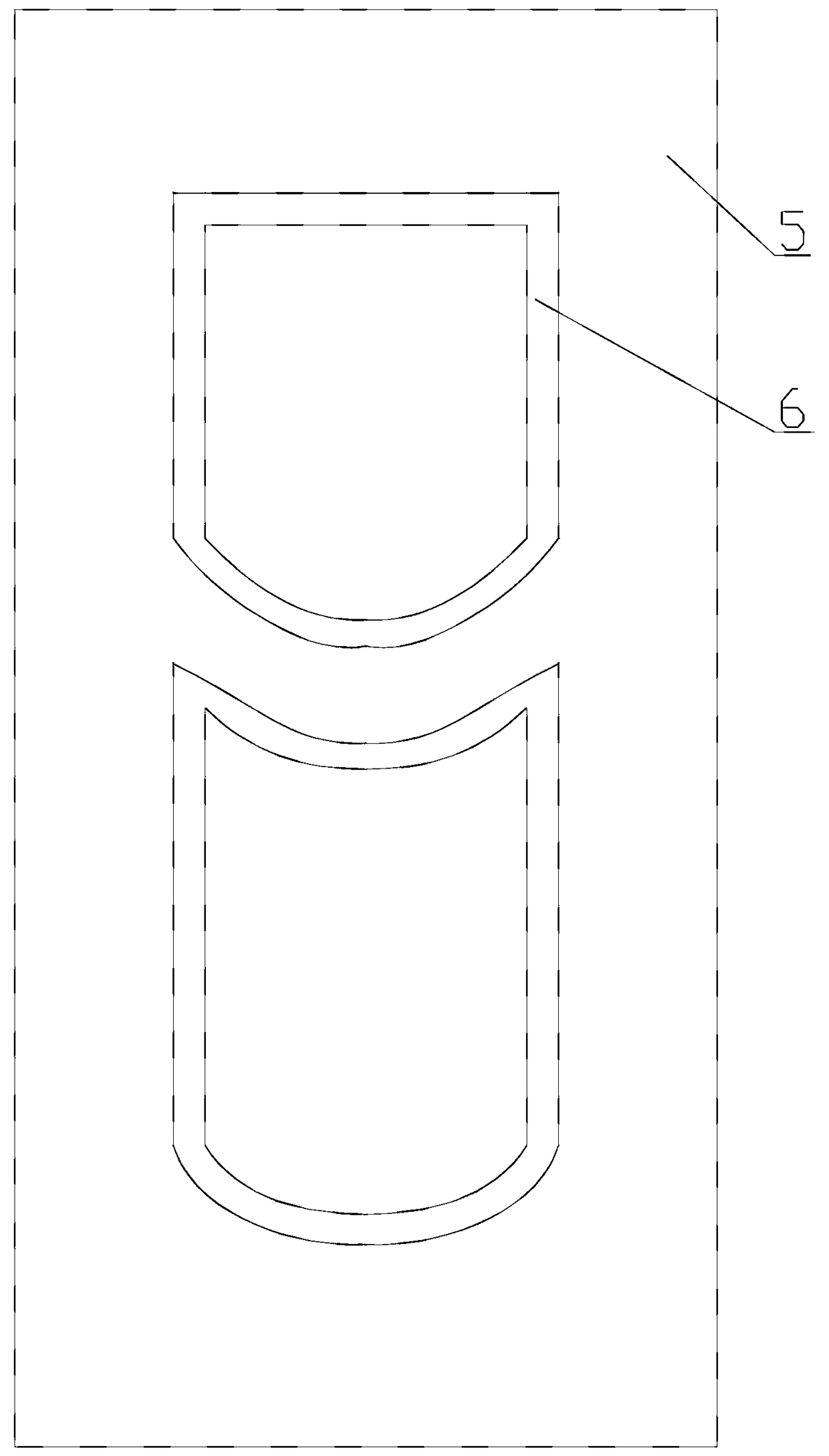

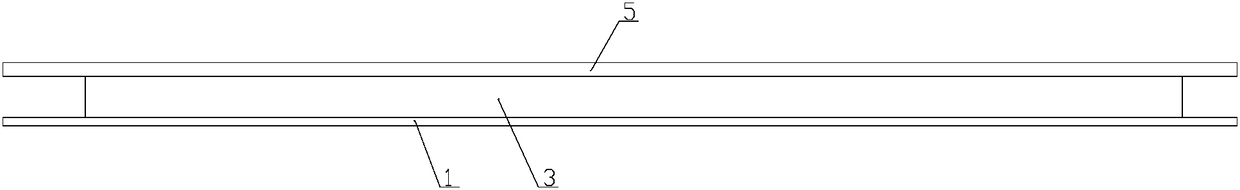

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-8 As shown, the lightweight high-strength waterproof door includes a base plate 1, a left frame 2 and a right frame 4 are fixedly installed on the upper surface of the base plate 1, and a front frame is installed on both ends of the left frame 2 and the right frame 4. 3 and the rear frame 7, honeycomb waterproof paper net 8 is installed inside the four frames, and a top plate 5 is installed on the top of the honeycomb waterproof paper net 8, and a plurality of annular grooves are processed on the top surface of the top plate 5 6. The above-mentioned door panel structure improves the quality of the door panel while ensuring its waterproof function, and the door panel has a simple structure, simple manufacturing process, low manufacturing cost, and can be produced in large quantities.

[0031] Further, the bottom plate 1, the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com