Method and apparatus for biomass instant gasification and combustion

A biomass, pyrolysis and gasification technology, applied in the direction of combustion method, gaseous heating fuel, gas fuel burner, etc., can solve the problems of insufficient material utilization, tar pollution, adding domestic garbage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for instant biomass gasification and combustion comprises the following process steps:

[0041] ①Material preparation: crush the dried crop straw and other biomass into fine materials, saw and cut wooden sticks, branches, etc. 30% of the solid organic domestic waste that cannot be processed by the "domestic biogas generator", and the plastic bags in it will be knotted and ballized, and the waste metals such as copper and aluminum mixed in the material will be picked out, and the resulting mixed material will After there is no natural overhead phenomenon, the main furnace (51) is smoke-free and cleans the feeding operation, and the material is preheated and dried by non-external heat in the main furnace (51);

[0042] ② Ignition of the main furnace: Use the electric air igniter (13) to quickly convert the air at room temperature into "excited superheated air", and then introduce it into the combustible materials in the furnace to cause free radicals, so as to re...

Embodiment 2

[0048] A method for instant biomass gasification and combustion, including five process steps: material treatment, main furnace ignition, pyrolysis gasification, purification and reforming, and gas combustion. In the step, the collected "tar liquid" is not subjected to "variable temperature gasification and the gasification product is mixed with air, and then introduced into the furnace again for secondary infrared heat storage, heat preservation, catalytic cracking and instant complete combustion"; in the "gas combustion" In the process, the waste heat in the furnace is not exported, but "add low-temperature spare materials to the furnace when the combustion is over", and use the newly added low-temperature materials to absorb the waste heat in the furnace and reduce the temperature in the furnace to suppress the pyrolysis gas of the materials in the furnace. The purpose of preventing secondary pollution; In addition, the infrared heating agent is zinc oxide (ZnO), aluminum ox...

Embodiment 3

[0051] A method for instant biomass gasification and combustion, including five process steps of material treatment, main furnace ignition, cracking gasification, purification and reforming, and gas combustion. Compared with [Example 1], in the "gas combustion" step , does not additionally export the waste heat in the furnace, but "add low-temperature spare materials to the furnace at the end of combustion", use the newly added low-temperature materials to absorb the waste heat in the furnace, and reduce the temperature in the furnace to suppress the pyrolysis and gasification of the materials in the furnace. The purpose of preventing secondary pollution; in addition, the infrared heating agent is silicon carbide (SiC); other than that, the remaining parts are exactly the same as [Example 1].

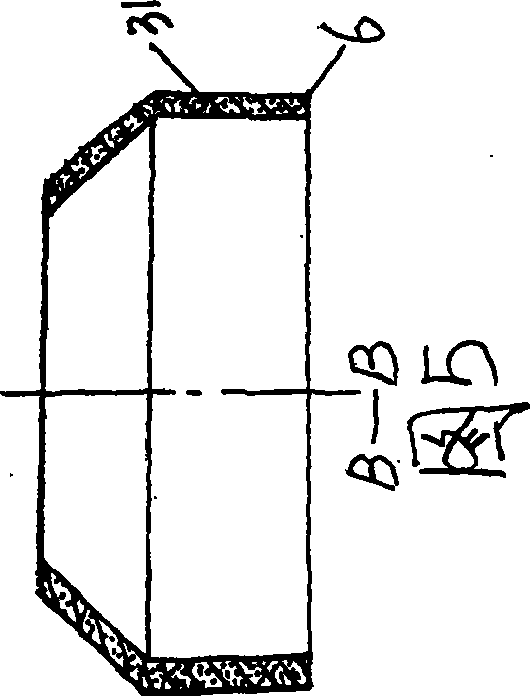

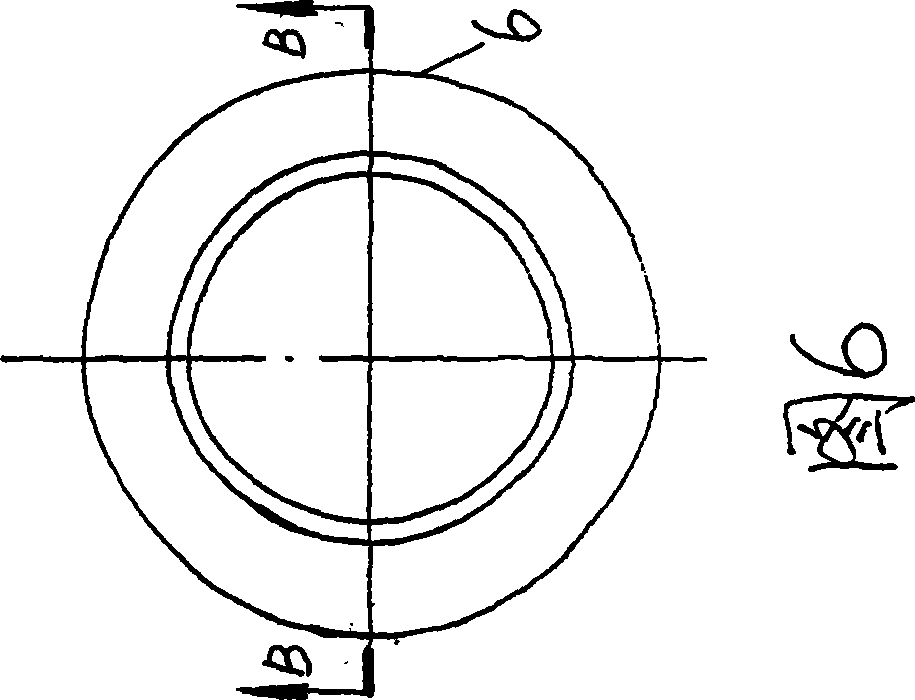

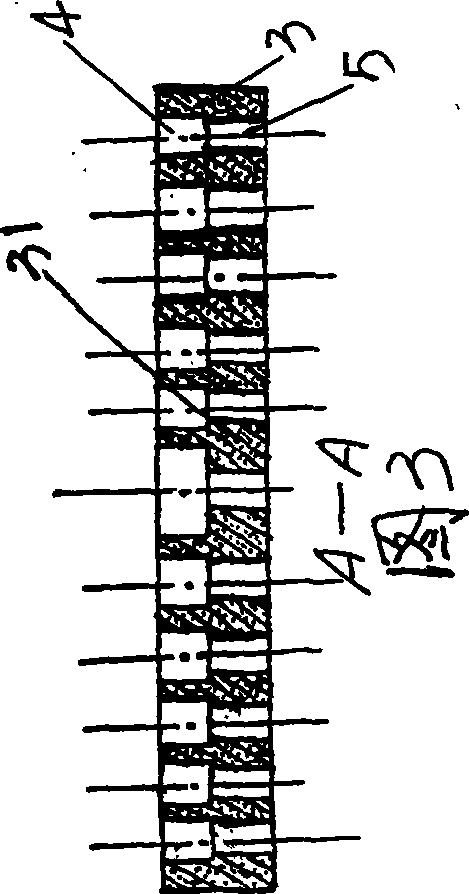

[0052] A biomass instant gasification combustion device for realizing the method described above, as shown in Figure 65, consists of a main furnace (51), a gas stove (107) and a pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com