Multifunctional air compressor

An air compressor and multi-functional technology, applied in the direction of electromechanical devices, mechanical equipment, machines/engines, etc., can solve the problems of reducing cooling wind, smooth air intake resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

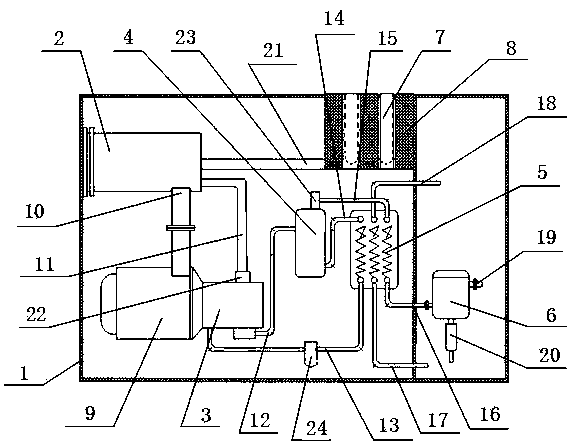

[0011] In this example, refer to figure 1 As shown, a multifunctional air compressor includes a chassis 1, and an air intake device (not shown), a motor (not shown), a booster air filter 2, a compressor 3, an oil and gas Separator 4, full heat recovery hot water machine 5 and centrifugal gas-liquid separator 6; the air inlet device (not shown) is provided with a filter bag 7 and a noise reduction pressure relief device 8, and the filter bag 7 is arranged on two Between the silencer and pressure relief device 8, the air outside the chassis 1 enters the chassis 1 after passing through the filter bag 7 to filter dust and the noise reduction and pressure relief device 8; the periphery of the motor (not shown) is provided with a motor cooling heat collector Cover 9, a heat collecting air duct 10 is arranged between the motor cooling heat collecting cover 9 and the pressurized air filter 2, the motor cooling heat collecting cover 9 collects the heat in the chassis 1 and transports i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com