Firework fuel gas driven high speed sprinkling device

A spraying device and gas technology, which is applied in the direction of liquid spraying device, spraying device, etc., can solve the problems of difficult shape of cloud and mist, easy formation of mushroom cloud, and difficulty of directional and concentrated spraying, so as to achieve easy control of cloud shape, long-term storage and production The effect of fast air speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

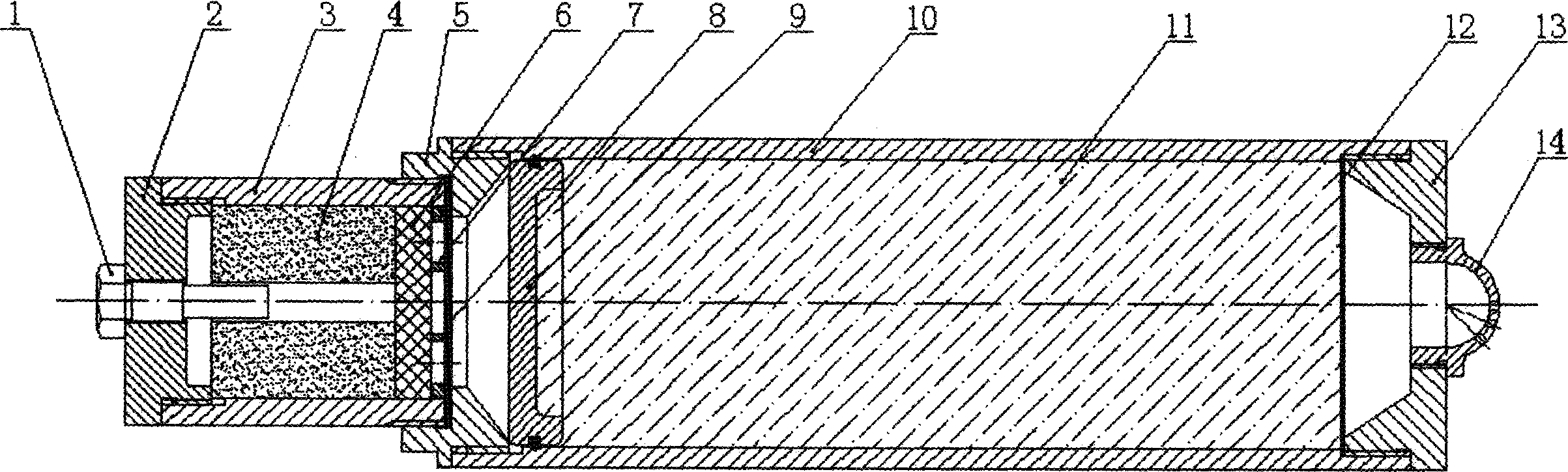

[0011] exist figure 1 Among them, the igniter (1), the gas generator end cover (2), the gas generator casing (3), the gas generating agent grain (4), the intermediate connector (5), the filter screen (6), the gas generator Exhaust port (7), copper sealing diaphragm (8), piston (9), liquid storage chamber casing (10), spray liquid (11), nozzle end sealing diaphragm (12), liquid storage chamber end cover (13 ), the nozzles (14) are arranged axially in turn to form a pyrotechnic gas-driven liquid high-speed spraying device. The gas generator shell (3) and the gas generator end cover (2) are connected by a threaded structure. In order to ensure the overall airtightness of the gas generator, the connection is sealed with a copper high-temperature and high-pressure gasket. The two shells (3, 10) The intermediate connector (5) is threaded, and the liquid storage chamber end cap (13) and the liquid storage chamber shell (10), the nozzle (14) and the liquid storage chamber end cap (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com