Household straw gasifying device

A gasification device and straw technology, applied in the field of household straw gasification device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

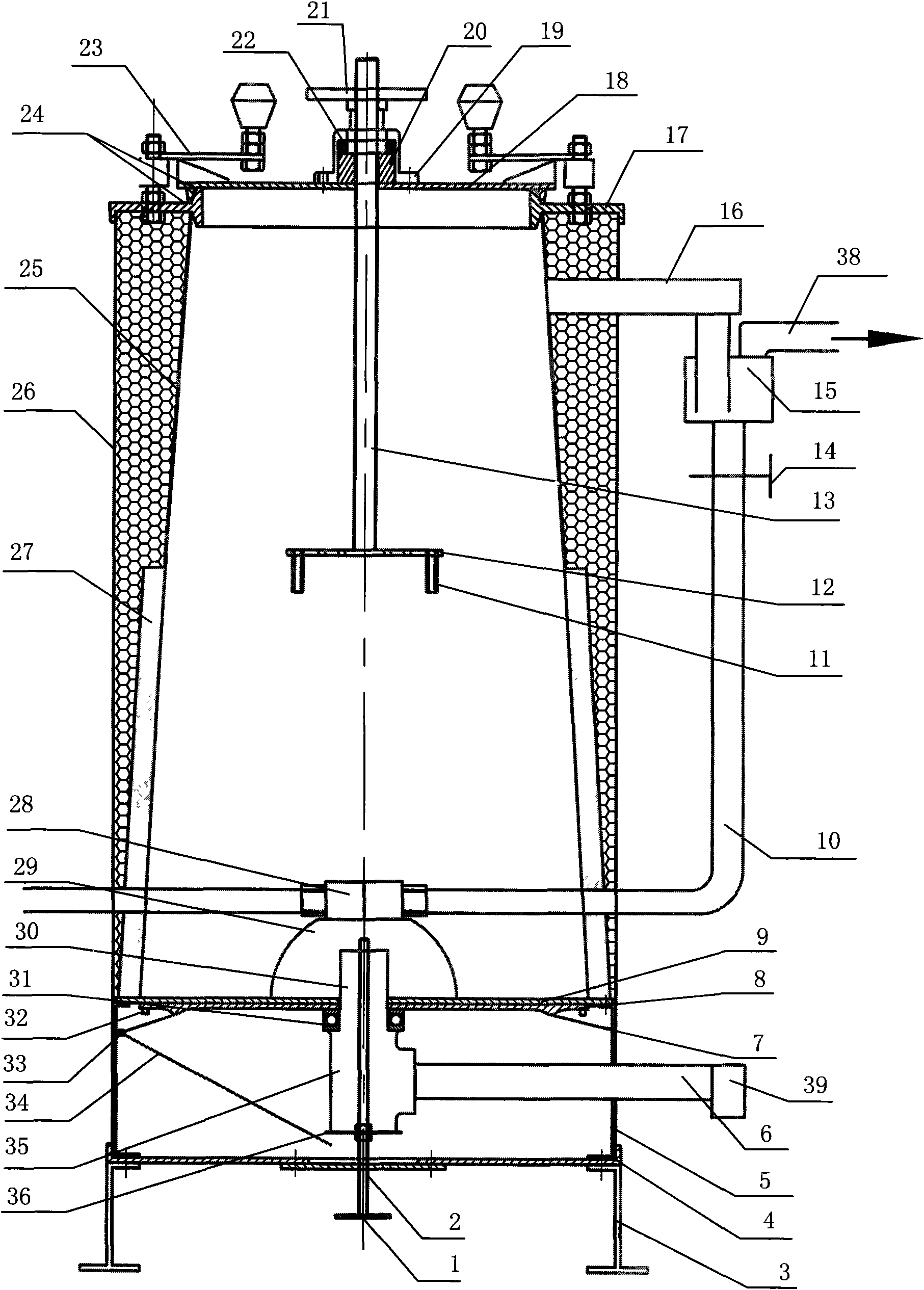

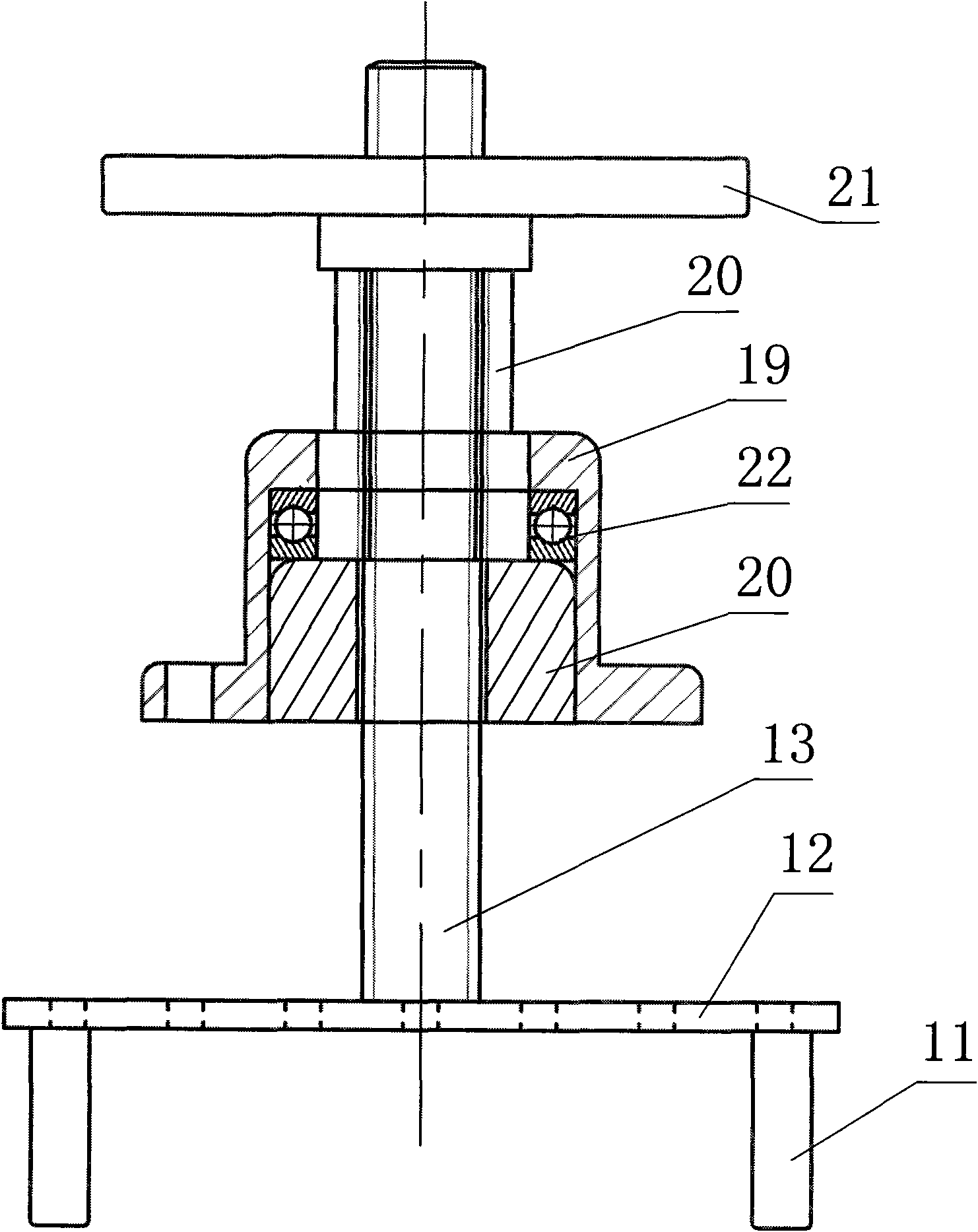

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] refer to Figure 1 ~ Figure 2 , a household type stalk gasification device, comprising a furnace body 26, a furnace cover 17 fixedly and sealingly connected with the upper end surface of the furnace body 26, and a furnace bottom 4 placed at the bottom of the furnace body 26, etc., the furnace cover 17 is provided with A top cover 18, a sealing ring 24 is added to the contact between the furnace cover 17 and the top cover 18, and the sealing ring 24 is preferably a silica gel pad; the center of the top cover 18 is provided with a material compacting device; Pressing sheets 23 are evenly distributed on the edge. When in use, turn the pressing sheets 23 to press the top cover 18 to make the sealing effect better; the lower end surface of the furnace body 26 is embedded with a large furnace tooth 9, and the large furnace tooth 9 and the support 5 is affixed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com