Method and device for recycling waste heat in discharged smoke of marsh gas power generation

A biogas power generation and waste heat technology, applied in steam engine installations, engine components, combustion engines, etc., to achieve the effect of easy technology, strong operability, and overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

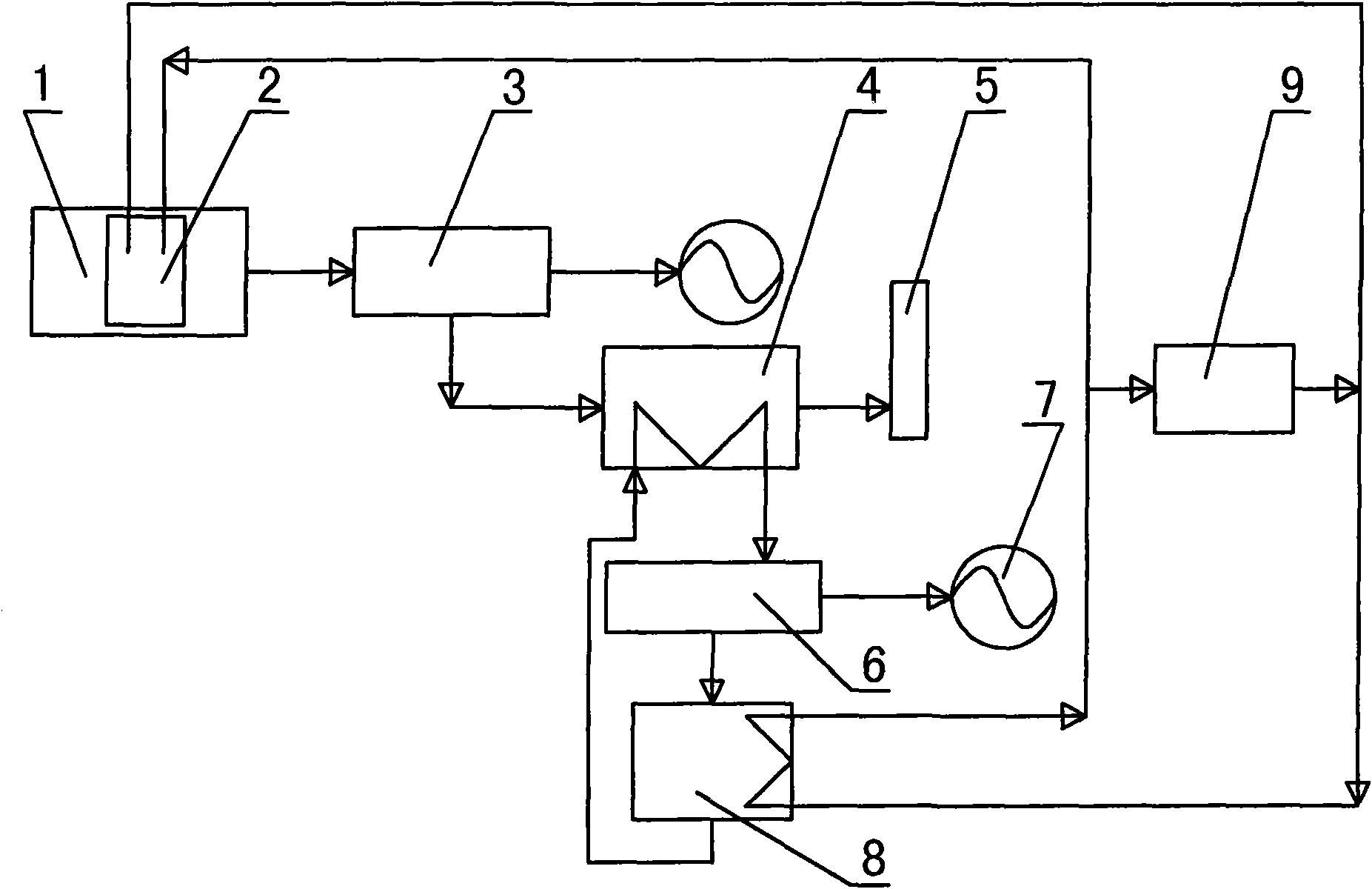

[0018] Embodiment 1 of the present invention: the method for recovering and utilizing the waste heat of exhaust gas generated by biogas power generation is as follows: the exhaust gas generated by the biogas internal combustion engine 3 enters the waste heat boiler 4 for heat exchange with water, the temperature of the flue gas is lowered, and the cooled flue gas passes through the chimney 5 Discharge; the saturated steam (pressure 0.7MPa~1.1MPa, temperature 200℃~280℃) produced after the water absorbs heat enters the screw expansion power machine 6 and the generator 7 for expansion and power generation, and the exhaust steam enters the condenser 8, and the condensed water Enter the waste heat boiler for 4 cycles. The temperature of the circulating cooling water in the condenser 8 rises after absorbing the heat released by the condensation of the exhaust steam. Part of the circulating water enters the fermenter 2 in the biogas system 1 to provide heat for the fermenter 2, and th...

Embodiment 2

[0020] Embodiment 2 of the present invention: the method for recovering and utilizing the waste heat of exhaust gas generated by biogas power generation is as follows: the exhaust gas generated by the biogas internal combustion engine 3 enters the waste heat boiler 4 for heat exchange with water, the temperature of the flue gas is lowered, and the cooled flue gas is discharged into the atmosphere The superheated steam (pressure 1.1MPa~1.5MPa, temperature 280°C~350°C) produced after water absorbs heat enters the screw expansion power machine 6 and generator 7 for expansion and power generation, exhaust steam enters condenser 8, and condensed water enters The waste heat boiler is used in 4 cycles. The temperature of the circulating cooling water in the condenser 8 rises after absorbing the heat released by the condensation of the exhaust steam. Part of the circulating water enters the fermenter 2 in the biogas system 1 to provide heat for the fermenter 2, and the rest of the circ...

Embodiment 3

[0022] Embodiment 3: The method for recovering and utilizing the waste heat of exhaust gas generated by biogas power generation is as follows: the exhaust gas generated by the biogas internal combustion engine 3 enters the waste heat boiler 4 for heat exchange with water, the temperature of the flue gas is lowered, and the cooled flue gas is discharged into the atmosphere; The saturated steam (pressure 0.3MPa~1.0MPa, temperature 135℃~250℃) generated after heating enters the screw expansion power machine 6 and the generator 7 for expansion and power generation, the exhaust steam enters the condenser 8, and the condensed water enters the waste heat boiler 4 recycle.

[0023] According to the above-mentioned method, the device for recovering and utilizing the waste heat of exhaust gas generated by biogas power generation includes a biogas internal combustion engine 3, a waste heat boiler 4, a screw expansion power machine 6, a generator 7 and a condenser 8, a biogas internal combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com