Method and device for removing hydrogen sulfide from gas containing hydrogen sulfide and recovering sulfer using catalytic oxidation

A technology for catalytic oxidation and hydrogen sulfide, applied in chemical instruments and methods, separation methods, catalysts for physical/chemical processes, etc., can solve the problems of low processing capacity, low conversion activity, complex process, etc., and achieve fast conversion speed and simple equipment. , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

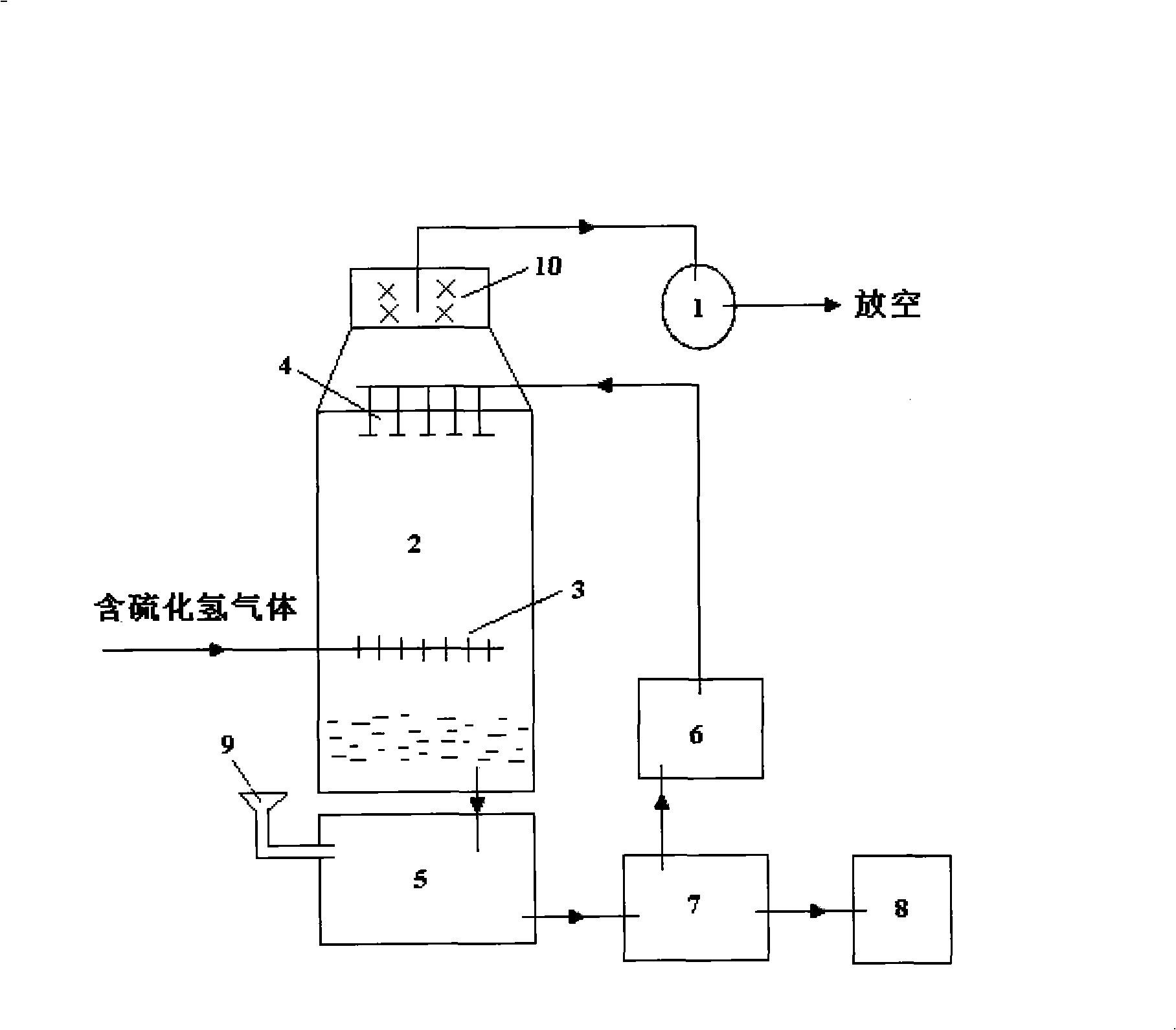

[0033] Taking the removal of the hydrogen sulfide odor gas produced by the fecal residue treatment plant, municipal solid waste transfer compression station, and public toilets as examples, the application process of hydrogen sulfide odor removal is described (see attached Figure 1 ).

[0034] The prepared hydrogen sulfide oxidation catalyst solution containing 0.1 mole of iron ions is diluted 10 times with tap water and injected into the liquid storage tank.

[0035] With the help of the negative pressure generated by the exhaust fan, the hydrogen sulfide content is reduced to 3.5mg / m 3 The malodorous gas in the upper space of the septic tank of the dung disposal site enters the desulfurization tower evenly through the gas distributor at the bottom of the spray oxidation tower, and contacts with the hydrogen sulfide oxidation catalyst solution sprayed down from the top of the tower in countercurrent. With the participation of inhaled air, a catalytic oxidation reaction is c...

Embodiment 2

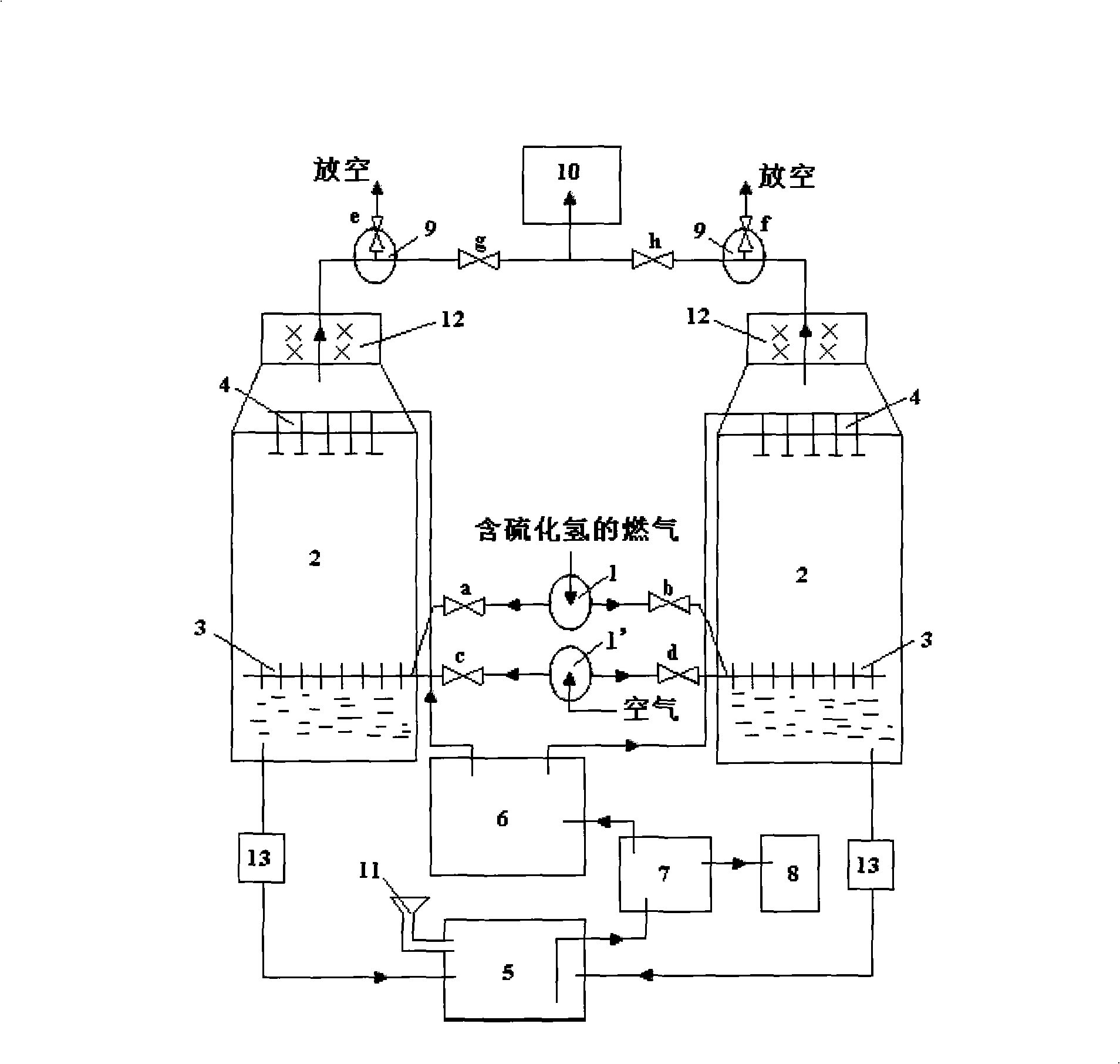

[0037] Taking the treatment of hydrogen sulfide in biogas, landfill gas and natural gas as examples, the process of removing hydrogen sulfide in combustible gas is described.

[0038] Combustible gases such as biogas, landfill gas and natural gas contain a large amount of hydrogen sulfide, generally at 0.1-12g / m 3 within range. When they are used as fuel, the hydrogen sulfide in them is converted into highly corrosive sulfurous acid mist, which pollutes the environment and corrodes equipment. In order to prevent the harm caused by hydrogen sulfide, desulfurization treatment must be carried out before using this kind of gas. The device disclosed by the present invention for removing hydrogen sulfide in combustible gases such as biogas, landfill gas and natural gas consists of two hydrogen sulfide catalytic oxidation towers with the same structure and related auxiliary equipment (see the appendix Figure II ). In the process of removing hydrogen sulfide, one of the towers is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com