Six-segment process for kitchen garbage to regenerate grease, bio-natural gas, medicinal fertilizer, feedstuff

A technology of bio-natural gas and kitchen waste, which is applied in the six-stage process of medicinal fertilizer and feed, bio-natural gas, and recycled oil from kitchen waste. Economic and social benefits, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

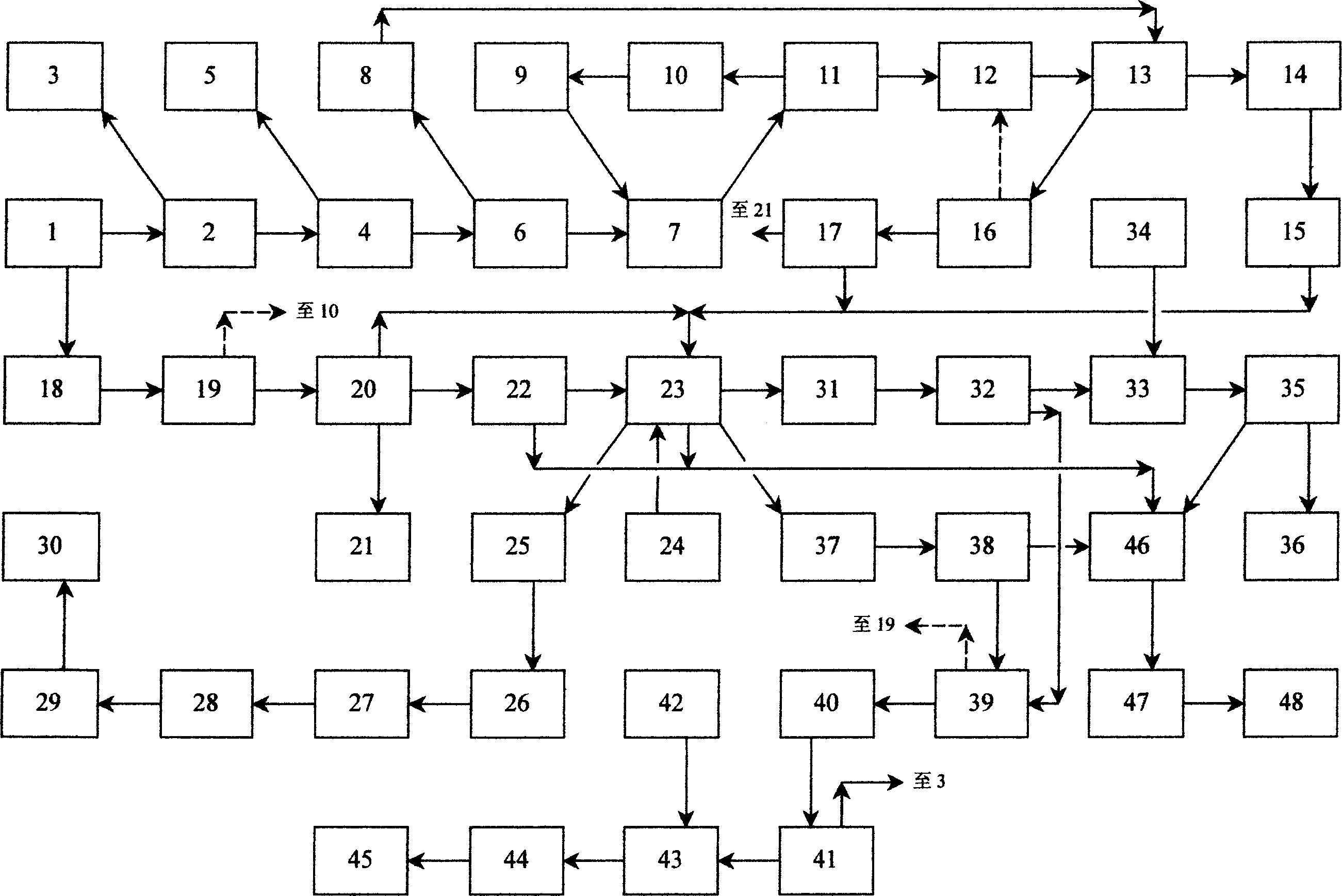

[0007] The accompanying drawings of the description are the process flow chart of the production line of the present invention

[0008] As can be seen from the accompanying drawings, the present invention includes a discharge chute 1, an even material sorting device 2, a waste bin 3, a magnetic separation conveyor 4, a magnetic waste bin 5, a vibrating sorter 6, a low level horizontal conveyor 7, and a return conveyor Machine 8, circulating conveyor 9, mixing storage tank 10, vertical conveyor 11, horizontal heating conveyor 12, press machine 13, pulverizer 14, fine material conveyor 15, thick mixed liquid heating storage tank 16, deoiling equipment 17 , dilute mixed liquid storage tank 18, heater 19, three-phase separator 20, oil tank 21, drainage control valve 22, bio-natural gas generating device 23, bio-natural gas auxiliary agent delivery equipment 24, biogas dehydration equipment 25, biogas pressurization equipment 26. Pressure gauge and one-way valve 27. Biogas desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com