Anaerobic fermentation technique for combined treatment of dejection and straw

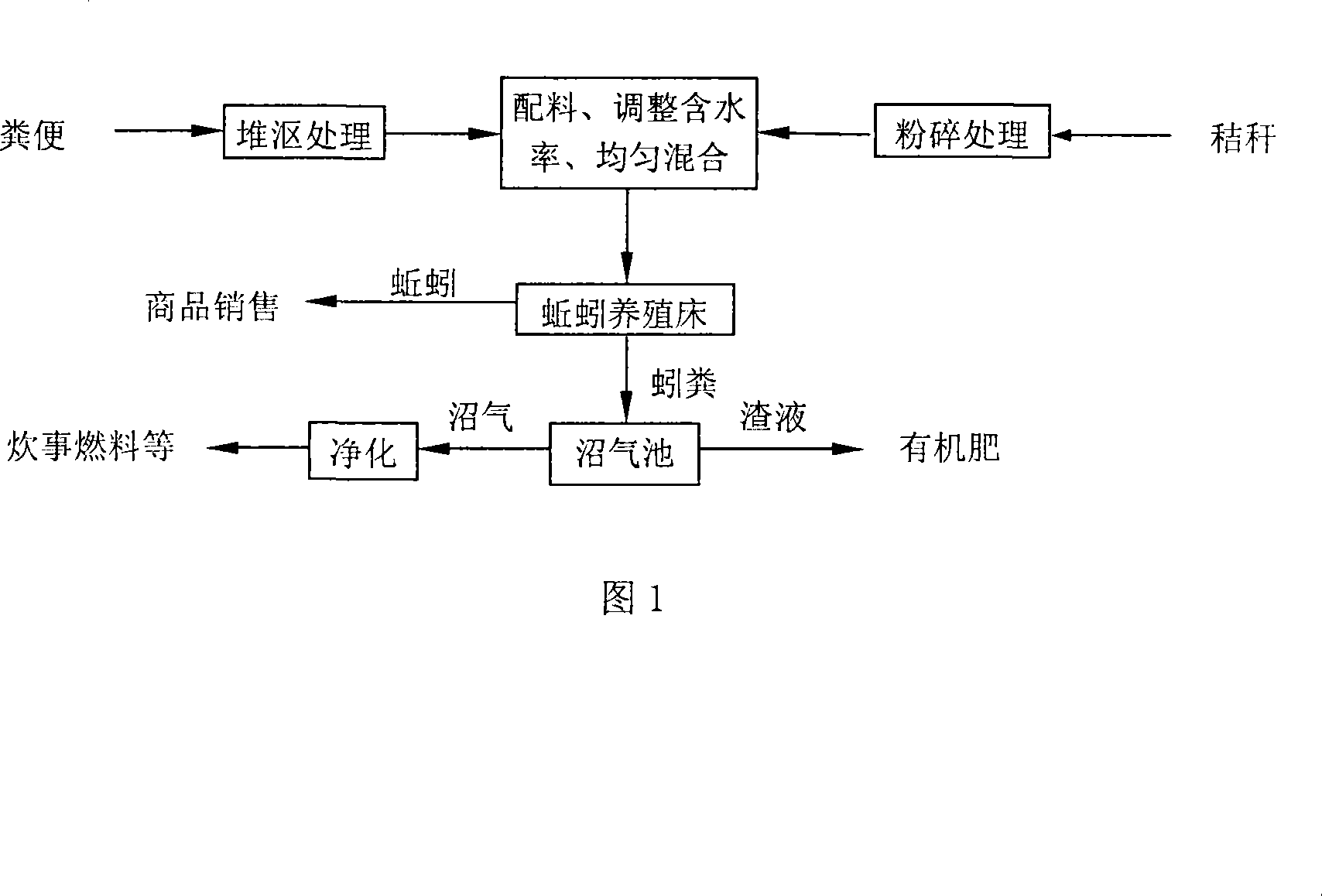

A technology of anaerobic fermentation and combined treatment, which is applied in the direction of fermentation, bio-organic part treatment, and organic fertilizer preparation. It can solve the problems of increasing the burden on farmers, stratifying raw materials, and limiting applications, and achieve the effect of improving economic output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The fresh pig manure is firstly retting, and the retting time is controlled at about 25 days. Crush the straw into 1-2cm particles, then mix the retting pig manure and straw according to the ratio of manure: straw = 7:3 (TS) and adjust the water content of the mixed raw materials after adjusting the C / N to 20 rate to around 65%.

[0025] Put the proportioned raw materials into the earthworm breeding bed for processing. The earthworm breeding bed adopts the method of building in the greenhouse, the accumulation height of raw materials is 15-20cm, and the temperature in the greenhouse is maintained at 20°C-25°C. Sprinkle water on the raw materials regularly every 1 to 2 days to maintain the moisture content of the raw materials. The species of earthworms is Eisenia chinensis, and the number of earthworms planted is about 8,000 per square meter of worm beds. Collect vermicompost every 15 days, and add new raw materials to the breeding bed at the same time. The collecte...

Embodiment 2

[0027]The fresh chicken manure is firstly subjected to stack retting treatment, and the stack retting time is controlled at about 30 days. Crush the corn stalks into 1-2cm particles, then mix the composted chicken manure and corn stalks evenly at the ratio of manure: straw = 6: 4 (TS) and adjust the C / N to 20, then adjust the mixed raw materials The moisture content is about 65%. Put the proportioned raw materials into the earthworm breeding bed for processing. The earthworm breeding bed adopts an open-air form, and the stacking height of the raw materials is 15-20 cm. The raw material pile is covered with straw to keep warm and keep moisture. Water is regularly sprinkled on the raw materials every 1-2 days to maintain the moisture content of the raw materials. The species of earthworms is Eisenia chinensis, and the number of earthworms planted is about 8,000 per square meter of worm beds. Collect vermicompost every 15 days, and add new raw materials to the breeding bed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com