Separator and separation and purification method of gas-liquid phase absorbing membrane

A liquid phase absorption and membrane separation technology, applied in separation methods, chemical instruments and methods, through absorption, etc., can solve the problems of complex technical operations, affecting separation effects, and high regeneration costs, achieving simple process and strong process compatibility. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

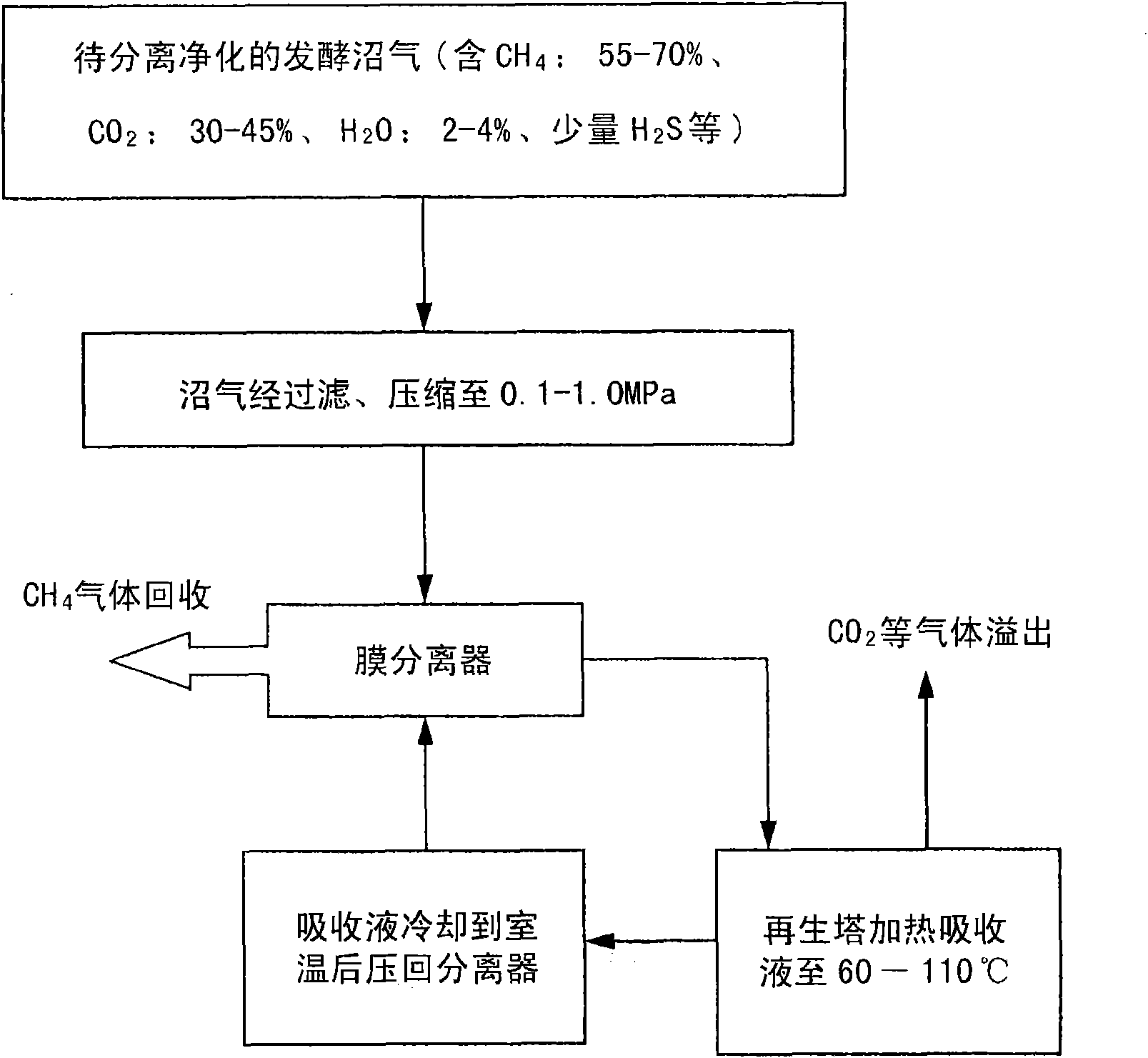

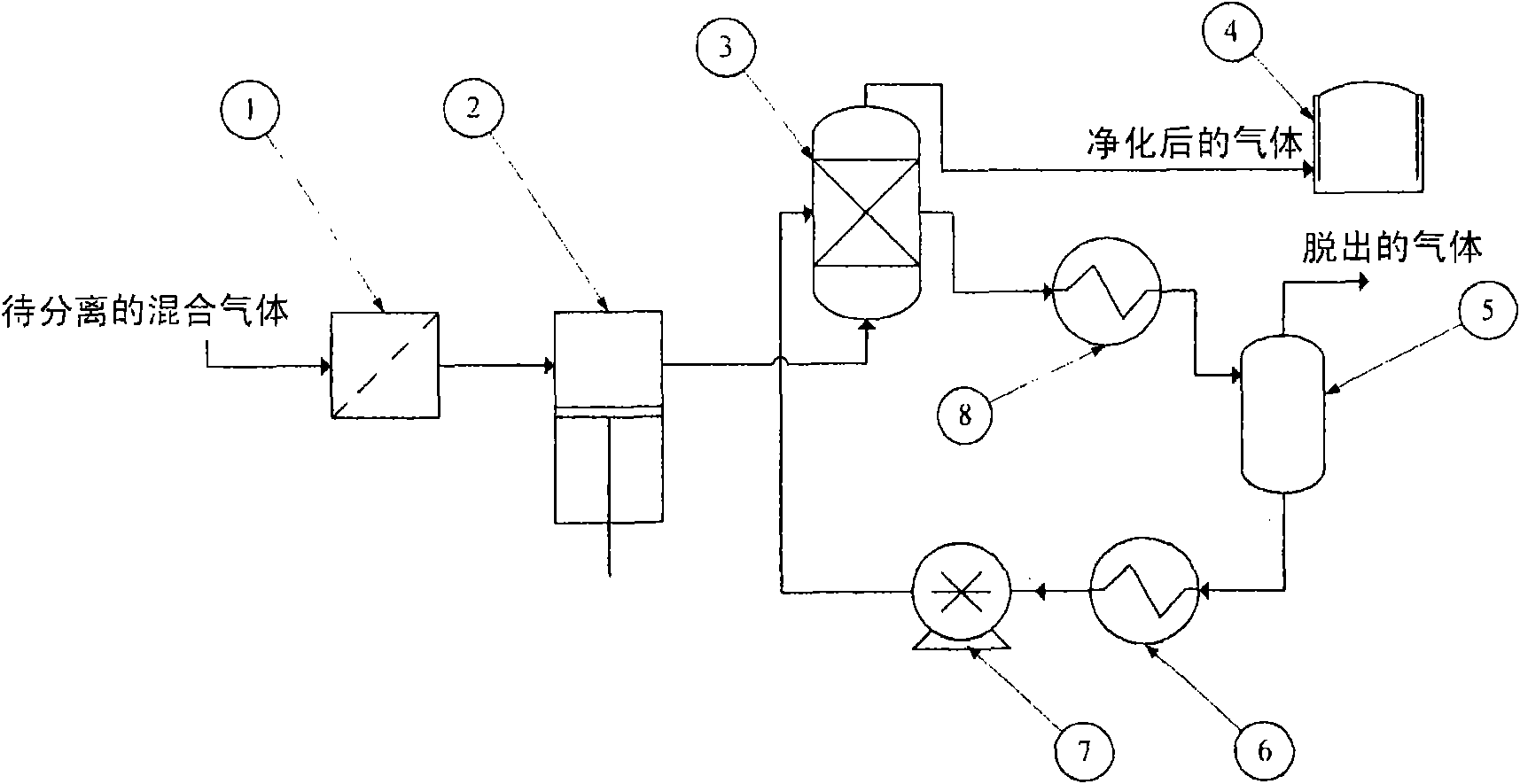

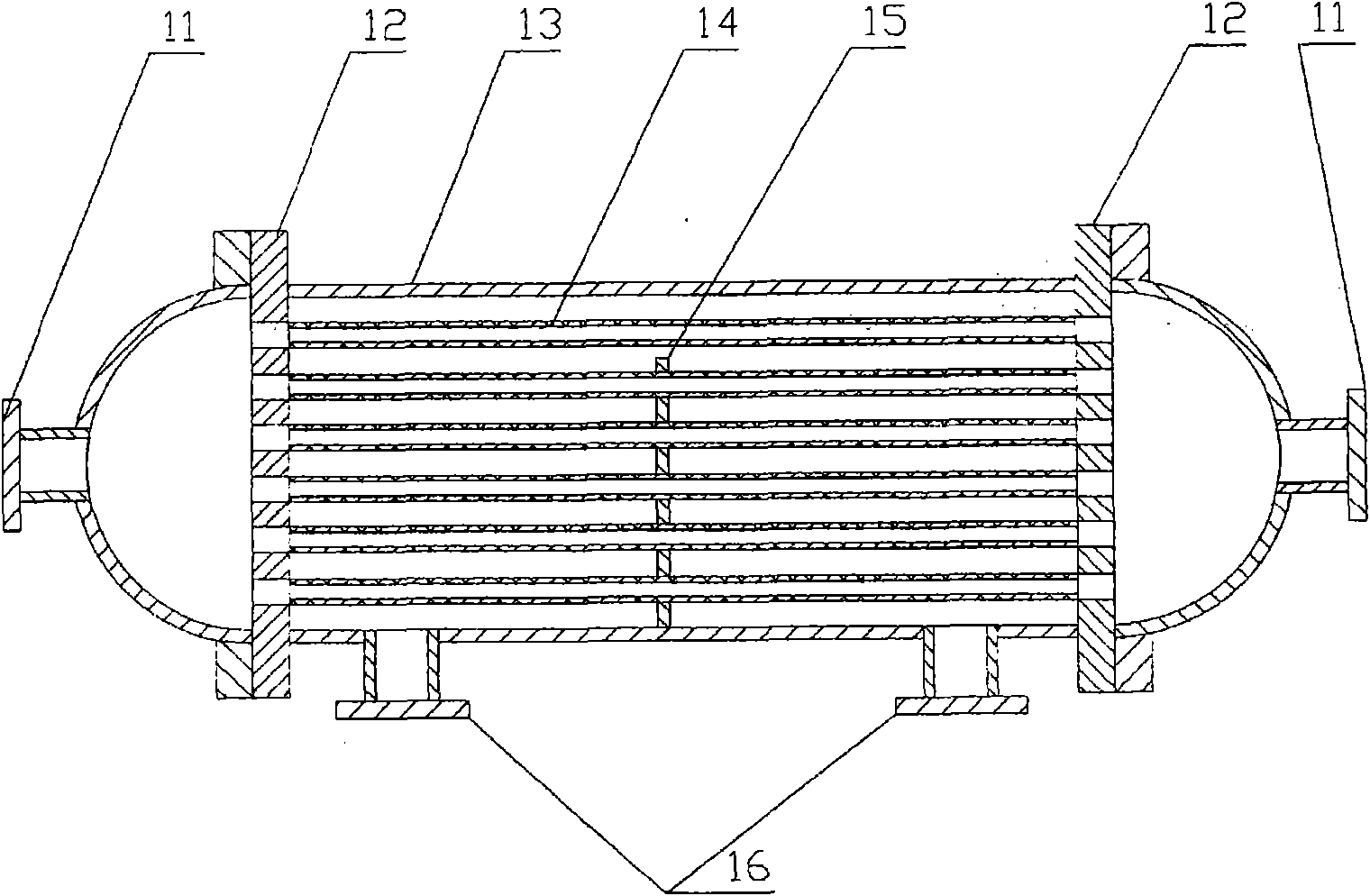

[0028] The gas phase-liquid phase absorption membrane separation and purification method of the present invention is: after the mixed gas to be treated is filtered and dedusted, it is compressed to 0.1MPa~1.0MPa by an oil-free compressor, and enters the gas phase-liquid phase membrane separator through the gas phase pipeline. . The gas phase passes through the gas phase side of the separation membrane, and the liquid phase absorbent flows through the other side of the separation membrane. The mixed gas that can pass through the separation membrane tube and can be dissolved in the liquid phase absorbent is absorbed by the liquid phase absorbent. , remove. It is not easy to pass through the separation membrane layer, and the gas that is hardly soluble in the liquid-phase absorbent stays on the gas-phase side to be purified and concentrated. The liquid-phase absorbent flows into the regeneration tower. According to the characteristics of the liquid-phase absorbent, the gas absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com